2

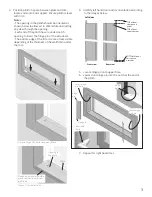

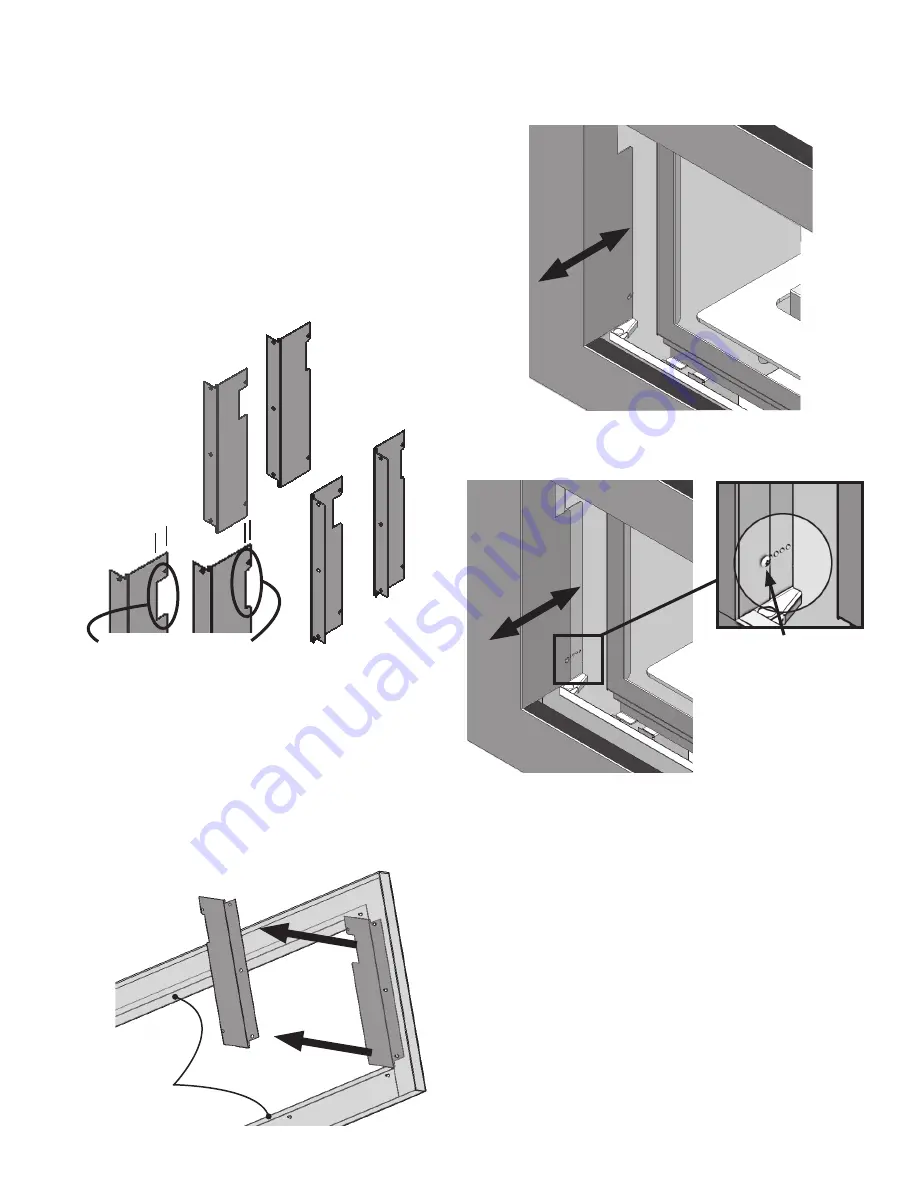

Installation

1. Locate trim inside perimeter of ‘window’ aperture

flanges, press firmly against finished face of wall.

2. Select a pre punched hole and secure trim using 4

no 8 screws.

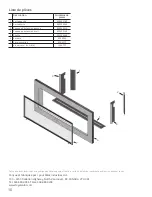

Note: The metal

flange is wider at the

top of the trim than

at the bottom

Top

Bottom

fixing

screws (4)

LH side

panels

RH side

pannels

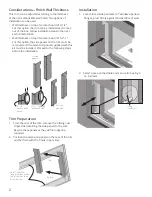

0 - 1/2”,

panels ‘deep’

notch

1/2” - 1”, panels

‘shallow’ notch

Considerations—Finish Wall Thickness

This trim can be adjusted according to the thickness

of the non-combustible wall finish. Two options of

installation can be used:

• Wall thickness on top of cement board of 0–1/2”.

For this option, the trim can be installed as it comes

out of the box. Follow installation steps in the next

section

Installation

.

• Wall thickness on top of cement board of 1/2”–1”.

For this option, the side panels on the trim must be

removed and the extension panels supplied with this

kit must be installed. Proceed to the following steps

before the installation.

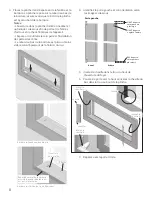

Trim Preparation

1. From the rear of the trim, remove the 6 fixing nuts

(3 per side) retaining the side panels to the trim.

Recycle these panels as they will no longer be

required.

2. Position the extension panels on the rear of the trim

and fix them with the 6 nuts (3 per side).