40

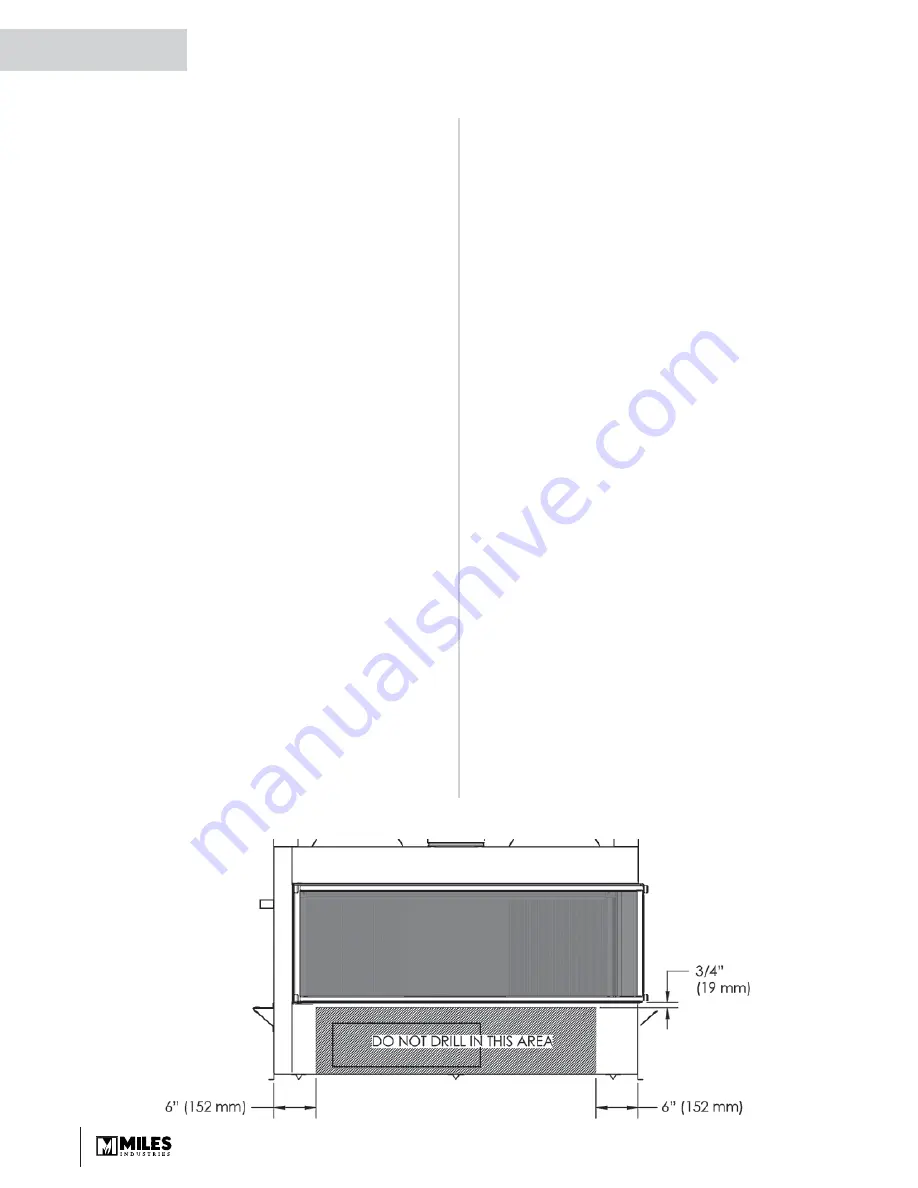

Applies to both LJ and RJ

corner appliances

Plan Wall Finish

Non-Combustible Materials Specifi cations

Material which will not ignite and burn. Such materials

are those consisting entirely of steel, iron, brick, tile,

concrete, slate, glass or plasters, or any combination

thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in a

Vertical Tube Furnace at 750 °C shall be considered

non-combustible materials.

Combustible Materials Specifi cations

Materials made of or surfaced with wood, compressed

paper, plant fi bers, plastics, or other material that

can ignite and burn, whether fl ame proofed or not,

or plastered or unplastered shall be considered

combustible materials.

Non-combustible cement board

The LX2 fi replace requires a 1/2” (13 mm) thick non-

combustible cement board to be used as a wall surface

immediately above the unit opening in the front and

above and behind the opening on each side.

Extending the cement board well beyond the minimum

will help avoid cracking due to diff erential expansion of

materials.

Pre-drill cement board with oversized holes and do

not over-tighten screws to avoid cracking due to heat

expansion.

Standard gypsum wall board may be used beyond the

perimeter of the cement board.

Non-combustible fi nishing over cement board

Additional non-combustible material such as tile, etc.,

may be applied over top of the cement board or you

may choose to leave it fi nished clean with no tile.

Cracking wall fi nishes

The LDK HeatShift Duct Kit reduces the wall tem-

peratures and minimizes the possibility of cracking

wall fi nishes.

If a clean fi nish with no tile, etc. is desired, joints in

the cement board and the transition to gypsum board

will require special attention if future cracking is to be

controlled. Be aware that temperatures on the non-

combustible wall surface above the appliance can

exceed 175°F.

Below are some tips on how to best avoid any

cracking:

• Allow materials to dry thoroughly before fi nishing

the wall. Cement board has the ability to absorb up

to 30 percent of its weight in water and may shrink

as much as 1/8” over a 48” length when drying from

a saturated condition. Running the fi replace before

fi nal fi nishing will help drive out moisture.

• Always pre-drill screw holes through cement board

and use screws with self-milling head.

• Always use tape over joints.

• Behind joints, double up studs or use studs “on the

fl at” to add extra support to the joint. Adhesive on

the backside of wall board behind any joints can

help control diff erential movement.

• Use multiple, thinner coats of joint compound and

allow to dry thoroughly between coats.

• Ensure framing materials are dry.

• After fi nishing the wall, introduce heat gradually to

slowly dry any excess moisture rather than drying

too fast.

• Avoid notching cement board or tiles around corners

of window opening and instead provide a joint that

intersects the corner.

INSTALLATION PLANNING

QUALIFIED

INSTALLER