SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

4

INSTALLATION

BEFORE OPERATION

1

1

2

2

3

3

4

4

5

WARNING

WARNING : To avoid possible personal injury

or equipment damage, a register electrician or

an authorized service representative should

perform installation and all service. Under no

circumstances should an unqualified person

attempt to wire into utility circuit.

Give the generator at least two feet of space from

any nearby wall to dissipate heat.

WARNING

WARNING: do not use a pipe carrying

combustible material as the ground

source.

WARNING

WARNING : To avoid back feeding into

utility system, isolation of the residence

electrical system is required. Before

temporary connection of a generator

to the residence electrical system turn

off the main switch. Before making permanent

connections a double throw transfer switch

must be installed. To avoid electrocution or

property damage, only a trained electrician should

connect generator to residence electrical system.

California law requires isolation of the residence

electrical system before connecting generator to

residence electrical system.

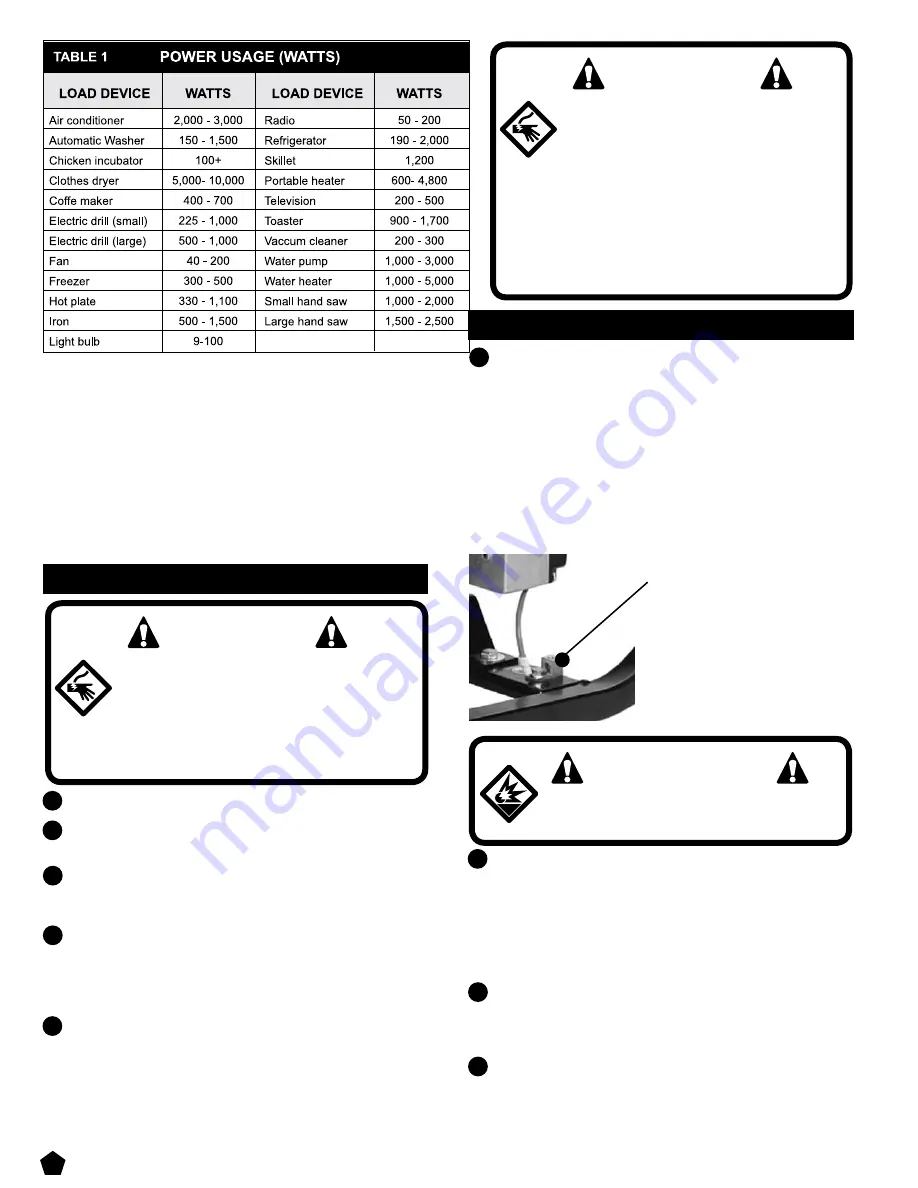

Generator Ground Terminal

A power line conditioner should be used when running

one or more of the following solid state items:

• Garage door openers.

• Kitchen appliances with digital displays.

• Televisions.

• Stereos.

• Personal computers.

• Quartz clocks.

• Copy machines

• Telephone equipment

Other solid state equipment may require a power line

conditioner, for more information contact customer

service.

To avoid back feeding into utility systems, isolation of

the residence electrical system is required.

Before temporary connection of the generator to

the residence system, turn off the main service

disconnecting device.

If your generator is to be used as a stand – by power

source in case of utility power failure, it should be

installed by a registered electrician and in compliance

with all applicable local electrical codes.

Proper use requires that a double throw transfer switch

be installed by licensed qualified electrician so that the

building’s electrical circuits may be safely switched

between utility power and the generator output; thereby

preventing back feed into the power utility’s electrical

system.

Always follow local codes and regulations that apply to

the installation of any item that concerns this product.

1. NFPA 70 – National Electrical Code.

2. NFPA 37 – Standard for Installation and Use of

Stationary Combustible Engines.

3. Agricultural Wiring handbook of Farm Standby Electric

Power.

GROUNDING THE GENERATOR

The National Electric Code requires that this product be

properly connected to appropriate earth ground to help

prevent electric shock. A ground terminal connected

to the frame of the generator has been provided for

this purpose. Connect a length of a heavy gauge (12

AWG min.) bare cooper cable between the ground lug

attached to the generator´s frame (identified with a label

with the ground symbol- see figure below) and a cooper

rod drawn 1 meter into the ground which should provide

a suitable ground connection. However, consult with

a local electrician to insure that local codes are being

adhered to.

Connect a bare # 12 AWG copper

cable from the ground terminal to

an earth grounding point

LUBRICATION

DO NOT attempt to start the engine without filling the

engine crankcase with the proper amount and type of

oil. Use SAE 30 oil.

Your generator has been shipped from the factory without

oil in the engine crankcase. Operating the unit without oil

can damage the engine and lose the warranty.

Fill the engine according to the engine manual (page

5).

LOW OIL PRESSURE

The engine is protected for low oil pressure in the

lubrication pump, this is indicated by the light on the side

of key switch. Do not try to start the engine if the light

does not turn off.

FUEL

Fill the tank with unleaded fuel, clean and new. You can

use regular-grade fuel as long as it has a high octane

value (at least 85 octane). Always use a fuel additive.

A fuel additive will minimize the development of fuel

Summary of Contents for G120MG2200RV

Page 1: ......

Page 10: ...SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE 10 WIRING DIAGRAM ...

Page 11: ...SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE 11 IDLE DOWN WIRING DIAGRAM ...

Page 12: ...SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE 12 G120 G135 SPARE PARTS LIST ...

Page 22: ...ESPECIFICACIONES SUJETAS A CAMBIO SIN PREVIO AVISO 22 DIAGRAMA DE CABLEADO ...