Valtir.com

17

Revision D February 2023

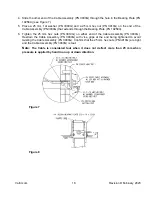

4. At Post location 4, fasten the Standard Guardrail (PN 10629G) and U-Bracket (PN 33461G) to

the 2000 mm C120 Post (PN 6183G) using a 16 mm x 50 mm Guardrail Post Bolt (PN

3400G), a rail nut (PN 3340G), and a flat washer (PN 3300G) (see Figure 6). The washer is

positioned between the post and the nut.

5. At Post location 3, splice the 4 m Anchor Guardrail (PN 29G) to the 4 m Standard Guardrail (PN

10629G) attached in Step 3 (above) using eight (8) 16 mm x 32 mm Guardrail Splice Bolts (PN

3360G) and rail nuts (PN 3340G).

Fasten a U-Bracket (PN 33461G) to the 2000 mm C120 Post (PN 6183G) using a 16 mm x50

mm Guardrail Post Bolt (PN 3400G), a rail nut (PN 3340G), and a flat washer (PN

3300G). The washer is positioned between the Post and the nut (see Figure 6)

Important:

Do not bolt the Rail Panels to Post 3.

6. At Post location 2, fasten the 4 m Anchor Guardrail (PN 29G) to the HBA Top Post 2 (PN

33877A) using a 16 mm x 50 mm Guardrail Post Bolt (PN 3400G), a rail nut (PN

3340G), and a flat washer (PN 3300G) (see Figure 1). The washer is positioned between

the post and the nut.

7. At Post Location 1, the 4 m Anchor Guardrail (PN 29G) must

not

be attached to the HBA Top

Post 1 (PN 33462A).

Important:

Do not bolt the Rail Panel to Post 1.

Cable Anchor Assembly

The Cable Anchor Bracket (PN 704A) is secured to the 4 m Anchor Guardrail (PN 29G) by inserting

the protruding hooks on the Cable Anchor Bracket (PN 704A) into the square slots in the Anchor

Guardrail (PN 29G). The Cable Anchor Bracket (PN 704A) is locked into place by pulling the bracket

towards the front end of the system.

1. Slide one end of the Cable Assembly (PN 3000G) into the Cable Anchor Bracket (PN 704A) and

the other end through the space between the HBA Top Post 1 (PN 33462A) and HBA Bottom

Post 1 (PN 33873A) (see Figure 7).

2. Place a 25 mm f at washer (PN 3900G) and a 25 mm hex nut (PN 3910G) on the end of the

Cable Assembly (PN 3000G) that extends through the Cable Anchor Bracket (PN 704A). Turn

the nut until at least 2 threads are completely through the nut.

3. Place the Bearing Plate (PN 19258A) [125 mm dimension up and the 76 mm dimension

down] in front of the HBA Top Post 1 (PN 33462A) and HBA Bottom Post 1 (PN 33873A) (see

Figures 7 and 8).

Note:

The tabs on the Bearing Plate (PN 19258A) rest on top of the HBA Top Post plates

(ears)

.

Warning:

Any grout, backfill, or other materials (such as concrete, asphalt, or soil)

must be low enough so as not to obstruct, constrain, or otherwise engage the bearing

plate. Failure to eliminate the interaction of soil or materials with the bearing plate will

hinder the performance of the EURO-ET™ system and could result in serious injury

or death in the event of a collision.

Summary of Contents for EURO-ET END TERMINAL

Page 1: ...PN 619489 REVISION D FEBRUARY 2023 EURO ETTM END TERMINAL PRODUCT DESCRIPTION ASSEMBLY MANUAL...

Page 24: ...Valtir com 23 Revision D February 2023 EURO ET Drawing...

Page 25: ...Valtir com 24 Revision D February 2023 Notes...

Page 26: ...Valtir com 25 Revision D February 2023 Notes...