---18---

C. General description

system, preprogrammed/preprogramed automatic

functions of Powershift--- for different driving conditions

and power shuttle.

The digital display panel in the tractor keeps the driver

informed by displaying the status of different operations,

e.g. driving direction, which of the Powershift--- gears is

engaged, chosen automatic operations, outdoor

temperature, it also shows when the PTO is engaged and

indicates any possible error function with a service code.

The main gearbox has 12 forward speeds and 12

reverse speeds. The 3---step Powershift gear on

tractors give 36 gears forward and 36 reverse gears.

Shafts and gearwheels in the gearbox are pressure

lubricated.

C 4.4.

Rear axle

The rear axle is fitted directly to the gearbox. The

differential lock in the rear axle is electro---hydraulically

controlled. When it is engaged, pressurized oil is pumped

to the multi---disc differential clutch, and this causes the

differential to lock. When the brake pedal is pressed the

differential lock is automatically disengaged. An indicator

lamp on the instrument panel lights when the differential

lock is engaged.

Final drives are of the planetary gear type. From the

planetary gears power is transmitted to the rear wheels.

C 4.5.

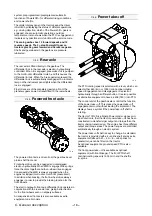

Powered front axle

T C10

The powered front axle is driven from the gearbox bevel

pinion shaft front end.

Front wheel drive can be engaged and disengaged

electro---hydraulically. When 4WD is engaged the springs

force the discs together and four---wheel drive engages.

Consequently the 4WD is always engaged when the

engine is stopped (multi---disc clutch not pressurized).

In addition when braking, the front---wheel drive always

engages in order to provide the braking function for the

front wheels.

The electro hydraulic front axle differential lock operates in

conjunction with the rear axle lock, giving better traction

for the front wheels even on slippery surfaces.

An suspensioned front axle is also available as extra

equipment on all models.

C 4.6.

Power take---off

T C11

The PTO rotating speed is selected with a lever, which can

select either 540 r/min or 1000 r/min nominal rotating

speed. Engagement and disengagement is electro---

hydraulically through a different button. It is also possible

as alternative equipment to have a 540E (750) r/min PTO.

The control unit of the gearbox also controls the function

of the power take---off. This makes the power take---off

engagement smooth without loading the implement. The

display shows a symbol if the power take---off shaft is

rotating.

The tractor T191LS is a Sigma Power model, whose prin-

cipal function is, that the tractor power take---off has been

constructed to transfer larger output and torque than the

tractor driving transmission. The engine has three different

output and torque areas. The power ranges are controlled

automatically through an electric system.

The power take---off shaft is easy to change. As standard

the tractor is provided with a 6---spline shaft and as extra

equipment shafts with 21---, 20---, 6--- or 8 splines for

greater torque can be fitted on the tractor.

As optional equipment a ground speed PTO is also

available.

The front power take---off is available as optional

equipment (with front linkage). The front PTO shaft

nominal rotating speed is 1000 r/min and the shaft is

6---spline.