Summary of Contents for VALMET 6000

Page 1: ...VALTRA VALMET MEGA MEZZO HI TEC WORKSHOP MANUAL...

Page 3: ...Order no 39 210 211 ENGLISH...

Page 4: ...10 General 11 Layout 12 Repairs 13 Maintenance...

Page 5: ...2...

Page 7: ...4...

Page 9: ...6...

Page 19: ...16...

Page 24: ...20 Engine 21 Engine 22 Fuel system 23 Cooling system 21...

Page 25: ...22...

Page 45: ...10 1 9 2002 6250 8950 210 18 1 8 2000 Model Code Page 21 Engine...

Page 46: ...11 1 9 2002 6200 8400 210 19 1 8 2000 Model Code Page 21 Engine...

Page 47: ...42...

Page 55: ...50...

Page 73: ...68...

Page 79: ...74...

Page 87: ...82...

Page 97: ...92...

Page 101: ...96...

Page 111: ...106...

Page 141: ...136...

Page 145: ...140...

Page 158: ...43 1 9 2002 310 6C 1 10 1999 6200 8550 Model Code Page 31 Tractor electrical system Not HiTech...

Page 159: ...44 1 8 2000 6250 8950 310 6D 1 10 1999 Model Code Page 31 Tractor electrical system HiTech...

Page 160: ...45 1 9 2002 6250 8950 310 6E 1 10 1999 Model Code Page 31 Tractor electrical system HiTech...

Page 161: ...46 1 9 2002 6200 8750 310 6F 1 10 1999 Model Code Page 31 Tractor electrical system Not HiTech...

Page 162: ...47 1 9 2002 6250 8950 310 6G 1 10 1999 Model Code Page 31 Tractor electrical system HiTech...

Page 163: ...156...

Page 166: ...159 Model Code Page 31 Tractor electrical system 8 11 1990 6100 8400 310 9 1 9 1992...

Page 167: ...160 Model Code Page 31 Tractor electrical system 8 11 1990 6100 8400 310 10 1 9 1992...

Page 171: ...164 Model Code Page 31 Tractor electrical system 6100 8400 310 14 15 5 1993 6184 130...

Page 172: ...165 Model Code Page 31 Tractor electrical system 6100 8400 310 15 15 5 1993 6184 132...

Page 175: ...168 Model Code Page 31 Tractor electric system 6000 8400 310 18 1 1 1994 318 716 30 B...

Page 176: ...169 Model Code Page 31 Tractor electric system 6000 8400 310 19 1 1 1994...

Page 177: ...170 Model Code Page 31 Tractor electric system 6000 8400 310 20 1 1 1994 Autocontrol...

Page 183: ...176...

Page 189: ...182...

Page 193: ...186 Model Code Page 31 Electrical system 1 4 1997 6000 8750 310 36 PT97 3 9 PT97 4 9...

Page 194: ...187 Model Code Page 31 Electrical system 1 4 1997 6000 8750 310 37 PT97 7 9 PT97 8 9...

Page 195: ...188 Model Code Page 31 Electrical system 1 4 1997 6000 8750 310 38 PT97 9 9...

Page 199: ...192 Model Code Page 31 Tractor electric system 1 11 1998 6250 8950 310 42...

Page 205: ...198...

Page 209: ...202...

Page 211: ...204 Model Code Page 31 Tractor electrical system 1 6 1999 6200 8750 310 54 AC 2 2 3 AC 2 2 4...

Page 212: ...205 Model Code Page 31 Tractor electrical system 1 6 1999 6200 8750 310 55 AC 2 2 5 AC 2 2 6...

Page 213: ...206 Model Code Page 31 Tractor electrical system 1 6 1999 6200 8750 310 56 AC 2 2 7 AC 2 2 8...

Page 217: ...210...

Page 220: ...213 Model Code Page 31 Tractor electrical system 1 10 1999 6250 8950 310 63 ACV V ACV VI...

Page 221: ...214 Model Code Page 31 Tractor electrical system 1 10 1999 6250 8950 310 64 ACV VII ACV VIII...

Page 222: ...215 Model Code Page 31 Tractor electrical system 1 10 1999 6250 8950 310 65 ACV IX ACV X...

Page 223: ...216 Model Code Page 31 Tractor electrical system 1 10 1999 6250 8950 310 66 ACV XI...

Page 227: ...220...

Page 229: ...222 Model Code Page 31 Trcator electrical system 1 8 2000 6250 8950 310 72 AC 5 2 3 AC 5 2 4...

Page 230: ...223 Model Code Page 31 Tractor electrical system 1 8 2000 6250 8950 310 73 AC 5 2 5 AC 5 2 6...

Page 231: ...224 Model Code Page 31 Tractor electrical system 1 8 2000 6250 8950 310 74 AC 5 2 7 AC 5 2 8...

Page 232: ...225 Model Code Page 31 Tractor electrical system 1 8 2000 6250 8950 310 75 AC 5 2 9 AC 5 2 10...

Page 234: ...227 Model Code Page 31 Tractor electrical system 1 8 2000 6250 8950 310 77 AC 5 2 13 AC 5 2 14...

Page 235: ...228...

Page 239: ...232...

Page 241: ...234 Model Code Page 31 Tractor electrical system 1 8 2000 6200 8750 310 84 AC 2 3 3 AC 2 3 4...

Page 242: ...235 Model Code Page 31 Tractor electrical system 1 8 2000 6200 8750 310 85 AC 2 3 5 AC 2 3 6...

Page 243: ...236 Model Code Page 31 Tractor electrical system 1 8 2000 6200 8750 310 86 AC 2 3 7 AC 2 3 8...

Page 244: ...237 Model Code Page 31 Tractor electrical system 1 8 2000 6200 8750 310 87 AC 2 3 9 AC 2 3 10...

Page 245: ...238 Model Code Page 31 Tractor electrical system 1 8 2000 6200 8750 310 88 AC 2 3 11...

Page 249: ...64 1 9 2002 6250 8950 310 92 Model Code Page 31 Tractor electrical system...

Page 251: ...66 1 9 2002 6250 8950 310 94 Model Code Page 31 Tractor electrical system HiTech L18105...

Page 252: ...67 1 9 2002 6250 8950 310 95 Model Code Page 31 Tractor electrical system HiTech L18105...

Page 253: ...68 1 9 2002 6250 8950 310 96 Model Code Page 31 Tractor electrical system HiTech L18105...

Page 254: ...69 1 9 2002 6250 8950 310 97 Model Code Page 31 Tractor electrical system HiTech L18105...

Page 255: ...70 1 9 2002 6250 8950 310 98 Model Code Page 31 Tractor electrical system HiTech L18105...

Page 256: ...71 1 9 2002 6250 8950 310 99 Model Code Page 31 Tractor electrical system HiTech L18105...

Page 257: ...72 1 9 2002 6250 8950 310 100 Model Code Page 31 Tractor electrical system HiTech L18105...

Page 261: ...76 1 9 2002 310 104 6200 8550 Model Code Page 31 Tractor electrical system...

Page 267: ...82 1 9 2002 310 110 6200 8550 Model Code Page 31 Tractor electrical system...

Page 285: ...256...

Page 288: ...89 Model Code Page 31 Power system 1 10 1999 8950Hi 313 4A 1 9 2002...

Page 289: ...260...

Page 291: ...262...

Page 292: ...91 Model Code Page 31 power system 1 8 2000 313 5A 1 9 2002...

Page 301: ...272...

Page 337: ...308...

Page 347: ...318 Model Code Page 1 11 1998 8450 8750 321 11A 32 ACB power lift Circuit diagram ACB...

Page 349: ...320 Model Code Page 1 6 1999 8450 8750 321 12 32 ACD Power lift 1 11 1998 ACD Power lift...

Page 350: ...103 Model Code Page 1 6 1999 6200 8150 321 13 32 ACB Power lift 1 9 2002 ACB Power lift...

Page 353: ...324...

Page 359: ...330...

Page 367: ...338...

Page 387: ...116...

Page 400: ...359 Model Code Page 34 Autocontrol III 6600E 8100E 340 13 15 6 1992 1 9 1992...

Page 401: ...360 Model Code Page 34 Autocontrol III 6600E 8100E 340 14 15 6 1992 1 9 1992...

Page 402: ...361 Model Code Page 34 Autocontrol III 6600E 8100E 340 15 15 6 1992 1 9 1992 Autocontrol ECS...

Page 403: ...362 Model Code Page 34 Autocontrol III 6600E 8100E 340 16 15 6 1992 1 9 1992 ECS...

Page 411: ...370...

Page 421: ...380...

Page 425: ...384...

Page 439: ...398 Model Code Page 35 Autocontrol IV 1 1 1995 6600E 8100E 8750E 350 14...

Page 443: ...402...

Page 447: ...406 Model Code Page 35 Autocontrol IV 15 5 1996 6600E 8750E 350 22...

Page 448: ...407 Model Code Page 35 Autocontrol IV 15 5 1996 6600E 8750E 350 23 E1 7...

Page 449: ...408 Model Code Page 35 Autocontrol IV 15 5 1996 6600E 8750E 350 24...

Page 450: ...409 Model Code Page 35 Autocontrol IV 15 5 1996 6600E 8750E 350 25...

Page 451: ...410...

Page 455: ...414 Model Code Page 35 Autocontrol IV 1 4 1997 6600E 8750E 350 30...

Page 456: ...415 Model Code Page 35 Autocontrol IV 1 4 1997 6600E 8750E 350 31 E1 7 E2 7...

Page 457: ...416 Model Code Page 35 Autocontrol IV 1 4 1997 6600E 8750E 350 32 E3 7 E4 7...

Page 458: ...417 Model Code Page 35 Autocontrol IV 1 4 1997 6600E 8750E 350 33 E5 7 E6 7...

Page 459: ...418 Model Code Page 35 Autocontrol IV 1 4 1997 6600E 8750E 350 34 E7 7...

Page 467: ...426...

Page 477: ...436...

Page 481: ...440...

Page 493: ...452...

Page 511: ...470...

Page 519: ...478...

Page 521: ...138...

Page 541: ...494...

Page 549: ...502...

Page 559: ...160...

Page 565: ...516...

Page 585: ...182 37 Autocontrol 5 2 K41107 371 26 6250 6850 1 9 2002 Model Code Page HiTech...

Page 586: ...183 1 9 2002 371 27 6250 6850 37 Autocontrol 5 2 L18105 Model Code Page HiTech...

Page 587: ...184 1 9 2002 371 28 8050 8950 37 Autocontrol 5 2 L18105 Model Code Page HiTech...

Page 595: ...546 Malli Modell Koodi Kod Sivu Sida...

Page 605: ...556...

Page 609: ...560...

Page 644: ...595 Model Code Page 3 18 06 1997 6000 8400 39 DPS CONTROL UNIT fitting 3...

Page 645: ...596...

Page 653: ...604...

Page 657: ...608...

Page 673: ...624 Malli Modell Koodi Kod Sivu Sida...

Page 679: ...630 Malli Modell Koodi Kod Sivu Sida...

Page 681: ...632...

Page 687: ...638...

Page 691: ...642...

Page 713: ...664...

Page 719: ...188...

Page 741: ...194...

Page 751: ...698...

Page 753: ...700...

Page 754: ...701 Model Code Page 42 Gearbox 1 6 1999 6250 8950 420 4B...

Page 755: ...702...

Page 795: ...206 Model Code Page 6250 8950 15C 440 44 DPS 1 9 2002 1 8 2000 HiTech...

Page 813: ...760...

Page 835: ...782...

Page 854: ...801 Model Code Page 45 Final drives 6000 8750 450 5 1 8 2000 15 5 1996...

Page 867: ...814...

Page 873: ...820...

Page 893: ...840...

Page 895: ...842...

Page 914: ...861 Model Code Page 46 Front PTO 1 8 2000 463 13F 6250Hi 6850Hi K41107...

Page 928: ...51 Service brakes 52 Parking brake 50 Brake system 875...

Page 929: ...876...

Page 941: ...238...

Page 949: ...892...

Page 953: ...896...

Page 985: ...928...

Page 1004: ...947 Model Code Page 61 Steering system 6000 8950 610 19 1 8 2000 TwinTrac AC 5 2...

Page 1005: ...948...

Page 1027: ...970...

Page 1029: ...972...

Page 1045: ...988...

Page 1051: ...994...

Page 1061: ...1004...

Page 1073: ...1016...

Page 1081: ...1024...

Page 1093: ...1036...

Page 1097: ...1040...

Page 1101: ...1044...

Page 1147: ...1090...

Page 1148: ...1091 70 Frame and wheels 71 Frame 72 Wheels...

Page 1149: ...1092...

Page 1159: ...1102...

Page 1163: ...1106...

Page 1167: ...1110...

Page 1173: ...1116...

Page 1174: ...1117 80 Cab and shields 81 Cabin 82 Shields 83 Air conditioning...

Page 1175: ...1118...

Page 1187: ...1130...

Page 1191: ...1134...

Page 1211: ...1154...

Page 1218: ...1161 Model Code Page FITTING INSTRUCTION 03 08 1993 6000 8400 3 89 ELECTRIC AIR FILTER 3 a b c...

Page 1219: ...1162...

Page 1221: ...1164...

Page 1223: ...1166...

Page 1225: ...1168...

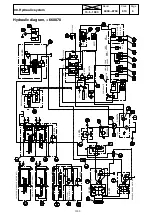

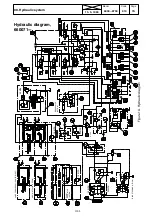

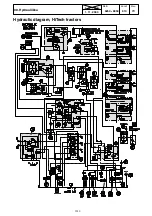

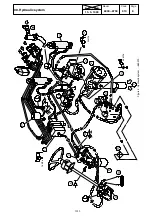

Page 1256: ...90 Hydraulics 91 Hydraulics 1199...

Page 1257: ...1200...

Page 1259: ...1202 Model Code Page 90 Hydraulic system 8 11 1990 6000 8750 910 2...

Page 1297: ...1240...

Page 1309: ...1252...

Page 1317: ...1260...

Page 1324: ...100 Special tools 101 Special tools ETV 102 Locally prepared tools ET 1267...

Page 1325: ...1268...

Page 1327: ...1270...

Page 1339: ...1282 Model Code Page 101 Special tools 15 5 1993 6000 8750 6B 101...

Page 1343: ...1286...

Page 1349: ...1292...

Page 1350: ...1293 Model Code Page 102 Locally prepared tools 1 4 1997 6000 8750 102 1 8 11 1990...

Page 1355: ...1298 Model Code Page 102 Locally prepared tools 1 1 1995 6000 8750 6 102 8 11 1990...

Page 1360: ...1303 Model Code Page 102 Locally prepared tools 1 1 1995 6000 8750 11 102 8 11 1990...

Page 1361: ...1304...