4.7

Periodical maintenance

5

20

30

40

50

0

5

0

20

25

30

1

GUID-56496CFD-9F29-4A47-9BBC-E980432028AF

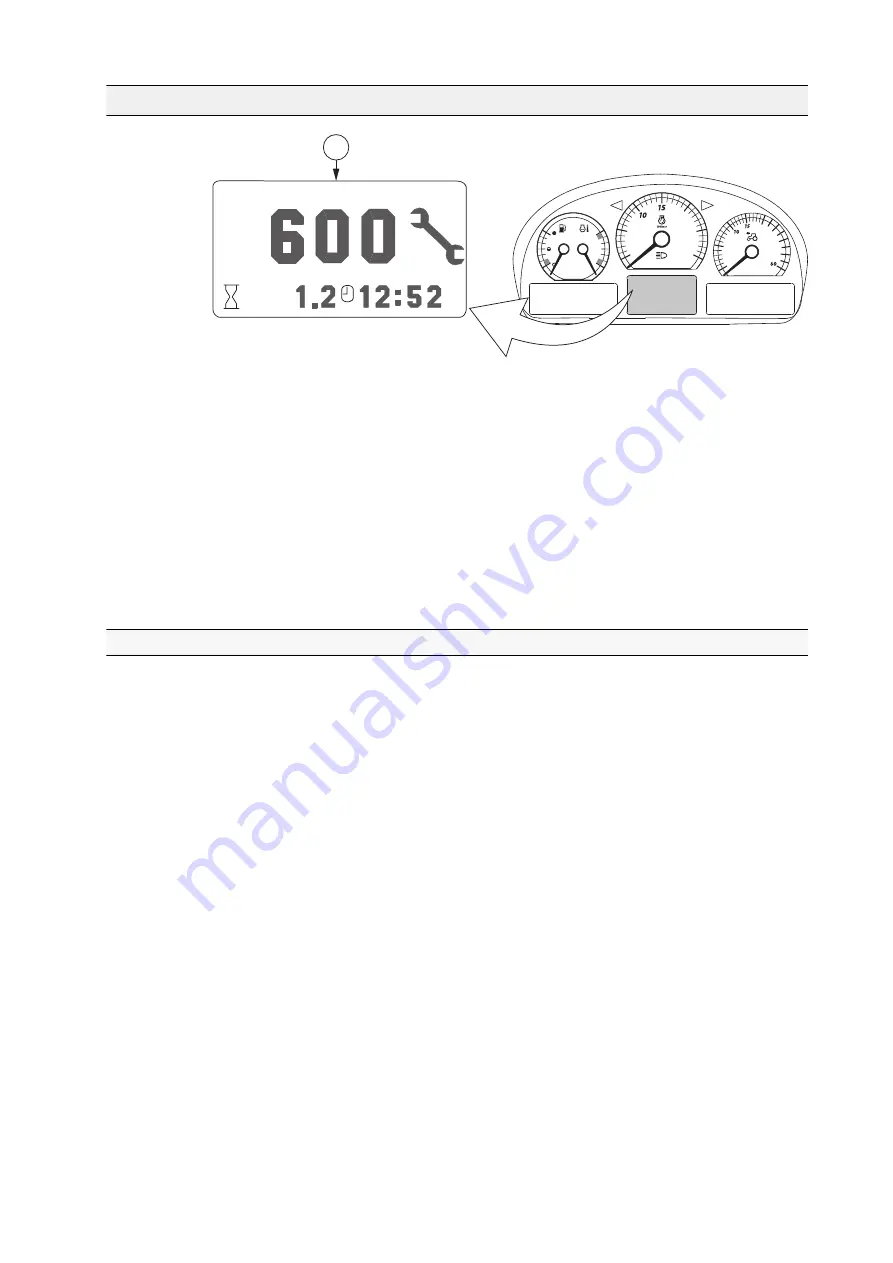

1. Periodical maintenance view

The periodical maintenance view shows when you must perform the tractor

service.

NOTE: When the periodical maintenance view is shown on the display, the

service work has to be carried out before the view is cleared.

NOTE: Clean the tractor before maintenance.

4.7.1

Periodical maintenance chart

You must follow the service intervals in the periodical maintenance chart.

IMPORTANT: When carrying out service you must follow the service intervals,

that is, you must also perform all previously required actions mentioned in the

periodical maintenance chart. For example, when doing 2400 hours service you

must also do the service required at 1200 hours, 600 hours, weekly and daily.

IMPORTANT: When using Biodiesel fuel there might be exceptions in the

periodical maintenance.

NOTE: The service intervals shown apply for normal operating conditions but in

more severe conditions servicing should be carried out more frequently.

•

The column 10 h shows the tasks that must be carried out daily or every 10

hours.

•

The column 50 h shows the tasks that must be carried out weekly or every 50

hours.

•

The column 600 h shows the tasks that must be carried out every 600 hours.

•

The column 1200 h shows the tasks that must be carried out yearly or every

1200 hours.

•

The column 2400 h shows the tasks that must be carried out every other year

or every 2400 hours.

4. Maintenance

- 343 -

Summary of Contents for Versu N Series

Page 1: ...OPERATOR SMANUAL NSERIES Versu Ref no 39 893 21 3 08 2015 YOUR WORKING MACHINE...

Page 2: ......

Page 517: ......