INSTRUCTIONS MANUAL

MISTLAIR MANUAL EXTERNAL MIX EQUIPMENT (PNEUMATIC PISTON PUMP)

16

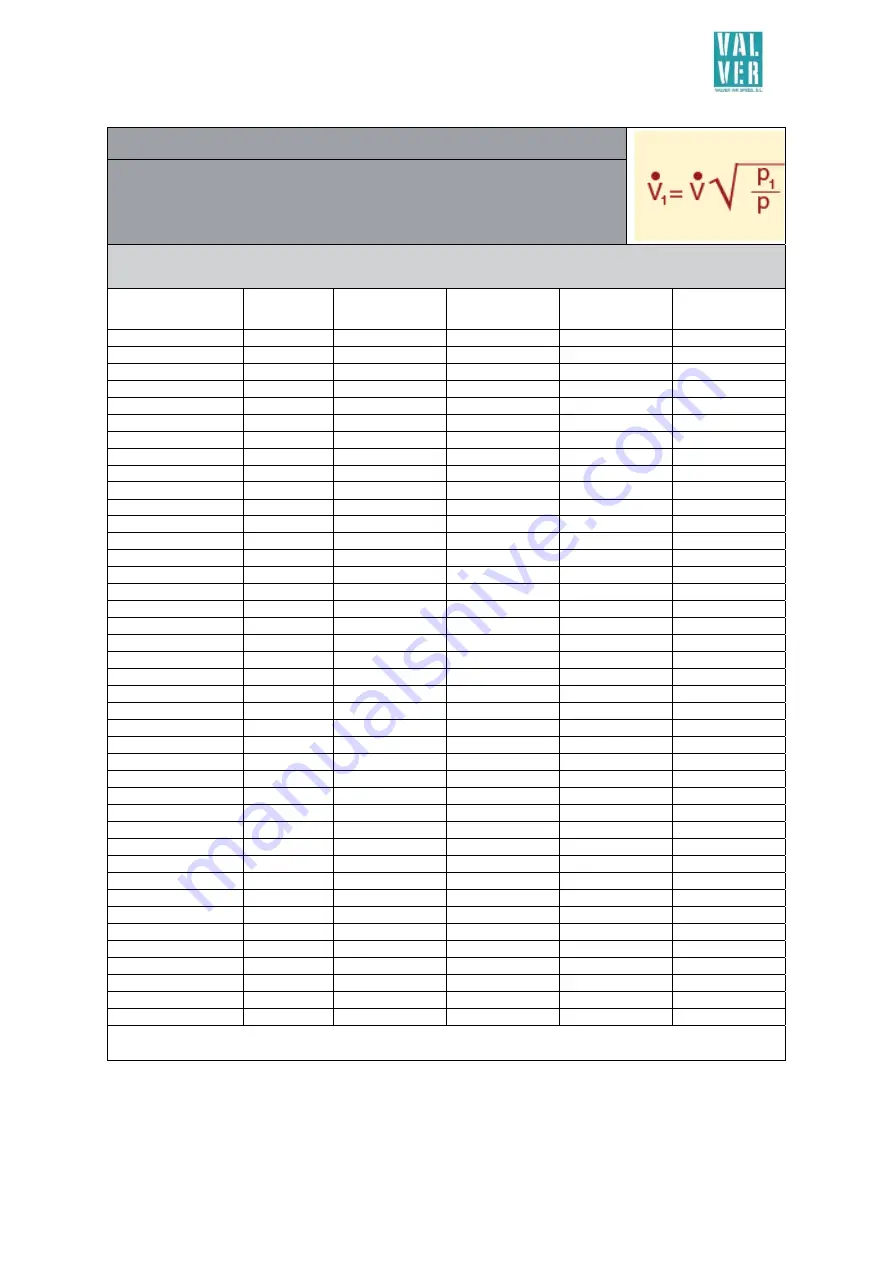

NOZZLE FLOW CHART

Flow (V)

The flow of a nozzle depends on a given fluid pressure nozzle inlet (the fluid

pressure in the nozzle). The rate may change due to pressure changes are

calculated using the formula:

Summary chart

Performance and the equivalent diameter of each nozzle size.

Equivalent

diameter, mm

L/min.

50 bar

L/min.

100 bar

L/min.

150 bar

L/min.

200 bar

L/min.

250 bar

0,13

0,065

0,092 0,112 0,130 0,145

0,18

0,124

0,176 0,215 0,249 0,278

0,23

0,203

0,287 0,352 0,406 0,454

0,28

0,301

0,426 0,521 0,602 0,673

0,33

0,418

0,591 0,724 0,836 0,935

0,38

0,554

0,784 0,960 1,109 1,240

0,43

0,710

1,004 1,230 1,420 1,588

0,45 0,778

1,100 1,347 1,555 1,739

0,48

0,885

1,251 1,532 1,769 1,978

0,53 1,079

1,525

1,868

2,157

2,412

0,58

1,292

1,827 2,237 2,583 2,888

0,63 1,524

2,155 2,640 3,048 3,408

0,66

1,673

2,365 2,897 3,345 3,740

0,68 1,775

2,511 3,075 3,551 3,970

0,73 2,046

2,894 3,544 4,092 4,575

0,78 2,336

3,304 4,046 4,672 5,224

0,84 2,709

3,831 4,693 5,419 6,058

0,89 3,041

4,301 5,268 6,083 6,801

0,94 3,393

4,798 5,876 6,785 7,586

0,99 3,763

5,322 6,518 7,526 8,415

1,04 4,153

5,873 7,193 8,306 9,286

1,09 4,562

6,451 7,901 9,124 10,201

1,14 4,990

7,057 8,643 9,980 11,158

1,19 5,437

7,690 9,418

10,875

12,158

1,24 5,904 8,349 10,226 11,808 13,201

1,29 6,390 9,036 11,067 12,779 14,288

1,32 6,690 9,461 11,588 13,380 14,960

1,35 6,998 9,896 12,120 13,996 15,647

1,40 7,526

10,643 13,035 15,051 16,828

1,45 8,073

11,417 13,983 16,146 18,051

1,50 8,639

12,218 14,964 17,278 19,318

1,55

9,225

13,046

15,978

18,450

20,627

1,57 9,464

13,385 16,393 18,929 21,163

1,60

9,830

13,901 17,025 19,659 21,979

1,65 10,453

14,783 18,106 20,907 23,375

1,70

11,097

15,693 19,220 22,193 24,813

1,75 11,759

16,630 20,367 23,518 26,294

1,80

12,440

17,593 21,548 24,881 27,818

1,83 12,859

18,185 22,272 25,717 28,753

1,85 13,141

18,584 22,761 26,282 29,385

1,91 14,007

19,810 24,262 28,015 31,322

Data base flow of wáter.

Summary of Contents for MISTLAIR

Page 1: ......