Page 11

CAUTION! Sand blasting is not permissible,

as it may destroy or damage critical surfaces.

R

EPAIR

AND

R

EWORK

Prior to re-assembly all the following components should be replaced or inspected and verified as

acceptable:

√

Packing

√

Body Gasket

√

Belleville Spring—Should be replaced if deformed or collapsed below the values of Table 3.

√

Ball and Seat

If no damage is evident the ball may be re-lapped to the seat, using methods outlined below:

If ball/end cap cannot be re-lapped. The seat must be re-machined, re-coated and re-lapped to the

new ball. This must be done by an approved ValvTechnologies facility.

The seat may be re-worked several times, as a rework face tolerance is designed into the end cap.

Contact ValvTechnologies for MOB Tolerance Ranges.

Other Valve Components:

In general these may be cleaned and returned to service.

If rework is required, consult ValvTechnologies Engineering Department.

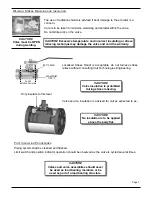

The ball is lapped to the end cap using 3-micron diamond

compound.

Ball is moved in a figure of eight motion against the end cap.

End cap is held and turned (at 30 r.p.m.) on a rotating table.

If no rotating table is available end cap is to be placed on

solid, clean surface and rotate by hand during lapping.

The ball/end cap seal shall be tested by sliding the mating

surface of the cleaned ball against the cleaned end cap seal

ing area. If a visible unbroken band appears the seal is

acceptable

(as shown to the right).

NOMINAL BORE SIZE

(inches)

SPRING HEIGHT (inches)

MINIMUM

MAXIMUM

5/8 .110 .126

1-1/8 .135 .150

1-1/2 .135 .160

2-1/8 .220 .240

3-1/16 .265 .290

3-1/2 .350 .362

4-1/16 .320 .340

5-1/8 .430 .460

6-1/16 .500 .530

7-1/8 .400 .430

8-1/16 .460 .500

10-1/16 .640

.680

TABLE 3 BELLEVILLE SPRING HEIGHTS