Page 6

INSTALLATION

R

ECEIVING

AND

P

REPARATION

P

ROCEDURE

1) Remove shipping protection.

2) Inspect valve for transportation damage.

3) Inspect valve bore and remove any debris.

4) Cycle the valve inspecting the ball for coating damage.

A

CTUATORS

CAUTION! Actuators are not to be

mounted, removed, adjusted or

re-installed to or from ValvTech-

nologies valves except by trained

ValvTechnologies personnel.

IMPORTANT!

Valves mounted with electric

actuators should be cycled to

the mid-stroke position before

cycling under power.

WARNING!

VALVES SHOULD NEVER BE USED AS A STRUCTURAL MEMBER.

O

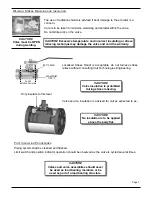

RIENTATION

CAUTION! Valves must be installed with the FLOW ARROW

pointing from high to low pressure with the valve in the closed

isolating position. Alternatively the high-pressure end will be

labeled. The high-pressure end is defined as the end with the

highest pressure, with the valve in the closed isolating position.

NOTE:

Uni-directional valves should not be installed in lines where a differen-

tial back pressure (from low to high pressure) of 200psi or more may exist.