Page 8

V

ALVE

L

UBRICATION

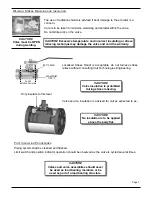

ValvTechnologies metal-seated ball valve requires NO lubrication.

Re-tightening of body (with system de-pressurized) and gland packing bolting

is permissible, if leakage occurs in these areas.

Required Torque values are given in Tables 1 & 2.

The use of Copper-Based Anti-Seize Grease for stud lubrication and Molyb-

denum Disulfide Anti-Seize Grease for packing lubrication is recommended.

Bolt Tension may be decreased to 25% shown in Tables 1 & 2 when other

or no lubrication is used.

TORQUE ft/lbs (Nm)

B7 OR

EQUAL

B8M OR EQUAL

5/16 (8)

12 (16)

4 (5)

3/8 (10)

18 (24)

6 (8)

7/6 (30)

29 (39)

9 (12)

1/2 (13)

45 (61)

13 (18)

9/16 (14)

50 (68)

19 (26)

5/8 (16)

85 (115)

26 (35)

3/4 (19)

150 (203)

45 (61)

7/8 (22)

240 (325)

70 (95)

1 (25)

355 (481)

110 (149)

1-1/8 (29)

510 (691)

155 (210)

1-1/4 (32)

700 (949)

210 (285)

1-3/8 (35)

950 (1288)

290 (393)

1-1/2 (38)

1250 (1695)

370 (502)

1-5/8 (41)

1600 (2169)

480 (651)

1-3/4 (44)

2060 (2793)

500 (678)

1-7/8 (48)

2500 (3390)

750 (1017)

2 (51)

3000 (4067)

900 (1220)

3 (76)

10300 (13965)

3100 (4203)

3-1/2 (89)

16500 (22371)

5000 (6779)

BOLT

SIZE -

INCHES

(mm)

TABLE 1

BODY BOLT TORQUE VALUES

TABLE 2

GLAND TORQUE

STUD

DIAMETER

NOMINAL

BALL

TORQUE VALUE in/lb (Nm)

THREAD

PITCH-

in (mm)

INSIDE

DIAMETER-

in (mm)

GLAND

TORQUE

NEVER

EXCEED

5/16 - 18 (8)

5/8 (16)

48

(5.4)

60

(6.8)

5/16 - 18 (8)

1-1/16 (27)

48

(5.4)

60

(6.8)

3/8 - 16 (10)

2-1/8 (54) 84

(9.5)

105

(11.9)

3/8 - 16 (10)

3-1/16 (78) 84 (9.5)

105

(11.9)

3/8 - 16 (10)

4-1/16 (103) 84 (9.5) 105

(11.9)

7/16 - 14 (11)

-

132

(14.9)

165

(18.7)

1/2 - 13 (13)

5-1/8 (13) 204

(23.1)

225

(25.5)

1/2 - 13 (13)

6-1/16 (154) 204 (23.1) 225 (25.5)

9/16 - 12 (14)

-

252

(28.5)

315

(35.6)

5/8 - 11 (16)

-

396

(44.8) 495 (56.0)

NOTE:

Due to the ValvTechnologies valve’s metal-to-

metal sealing surface operating torques are consid-

erably higher than comparable soft seated ball valves.

OPERATION

Note: Values are for B8M, Class 1 bolting.