Page 9

S

TEM

R

OTATION

D

IRECTION

AND

V

ALVE

P

OSITION

I

NDICATION

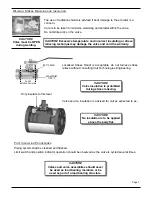

Typical valve hand wheels and levers require

80 lbf. (335N) of handle force to operate.

80 lbs. to

CLOSE

Lever operated are shown to be open when

the handle lies on the same axis as the valve

bore. The valve indicated closed when the

handle is at 90

o

to the valve bore.

A

CTUATOR

O

PERATION

Valve actuators must be installed, operated and maintained as per their manufacturer’s written

instruction. In the event of a conflict between these instructions and those contained in this manual an

authorized ValvTechnologies distributor or to ValvTechnologies Houston facility should be contacted.

The lubricant of worm gear actuators should be inspected every three months and be replenished or

replaced if required.

On actuated and gear-operated valves an arrow

shows the valve position.

The stem, gland and ball (and in some instances the

drive sleeve) bear markings as shown to the left. The

marks will line up on the left of a closed valve, when

looking down on the stem and facing downstream.

All ValvTechnologies ball valves (unless spe-

cifically stated) are operated clockwise to

close and counter-clockwise to open.

CAUTION! During disassembly

particular care should be taken

not to damage mating, packing,

or sealing surfaces.

CAUTION! Packing must be re-

placed if gland nuts are loose.

Only approved ValvTechnolo-

gies packing shall be used.

MAINTENANCE

WARNING!

DISASSEMBLY AND REPAIR OF VALVTECHNOLOGIES VALVE

ASSEMBLIES BY UNAUTHORIZED PERSONNEL MAY BE HAZARDOUS AND

NEGATE WARRANTIES.

D

ISASSEMBLY