PRINTED IN THE U.S.A.

PAGE 3

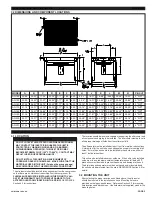

SPECIFICATIONS AND DIMENSIONS

SECTION 3

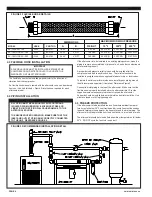

INSTALLATION

SECTION 4

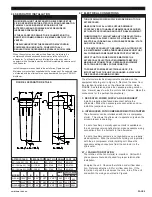

4.1 LOCATION

CAUTION

DO NOT LOCATE THIS AFTERCOOLER WHERE PERSONNEL

MAY CONTACT THE INLET PIPING UNLESS THE UNIT IS

PROTECTED BY WARNING SIGNS AND/OR A BARRIER.

DURING NORMAL OPERATION, THE INLET PIPING MAY

BECOME EXTREMELY HOT (150

O

F TO 400

O

F). CONTACT MAY

RESULT IN SERIOUS PERSONAL INJURY.

DO NOT INSTALL THIS UNIT IN AN ENVIRONMENT OF

CORROSIVE GASES OR CHEMICALS. MAKE SURE THAT THE

MATERIALS USED IN THIS UNIT (listed on the previous page)

ARE COMPATIBLE WITH THE ATMOSPHERIC CONDITIONS.

The aftercooler should be located far enough away from the compressor

so that there are no vibrations transmitted from the compressor.

A

FLEXIBLE HOSE MUST BE INSTALLED IN THE PIPING TO VALI-

DATE THE WARRANTY AND TO PREVENT DAMAGE TO THE

AFTERCOOLER FROM VIBRATION IN THE PIPING!

REFERENCE

Section 4.3 for instructions.

The location should be level and capable of supporting the aftercooler and

all components and piping to be installed. The aftercooler must be level to

allow proper drainage of fluids from the outlet manifold.

The aftercooler must be installed at least 1 foot from walls or obstructions.

It is important for the unit to have an adequate air supply for cooling at all

times. If more than one unit is to be installed in the same area, allow at

least 1 foot between them.

This unit can be installed indoors or outdoors. If the unit is to be installed

outdoors or in an area where ambient temperatures can fall below 35

o

F,

precautions must be made to prevent freeze-up and damage to the unit.

The drain lines and separator must be heat traced and/or insulated and

the unit should be protected from the wind. REFERENCE Section 4.5 for

details.

4.2 MOUNTING THE UNIT

After selecting the proper location as outlined above, the aftercooler

should be mounted to the installation surface. Mounting holes are

provided on the leg support braces. Reference Section 3.2 for mounting

hole locations and dimensions. Use hardware (not supplied) sized for the

mounting holes.

3.2 DIMENSIONS AND COMPONENT LOCATIONS

MODEL

AC-140

AC-150

AC-160

AC-170

AC-180

AC-190

AC-200

AC-210

AC-220

A

22.68"

30.56"

37.24"

41.19"

41.19"

51.04"

49.07"

51.04"

51.04"

B

34.20"

34.20"

36.01"

36.01"

36.01"

36.01"

36.01"

36.01"

36.01"

C

17.96"

22.37"

26.78"

26.78"

34.89"

37.88"

43.70"

52.52"

56.30"

D

32.35"

32.35"

33.25"

33.25"

33.25"

33.25"

33.25"

33.25"

33.25"

E

1.77"

1.77"

1.77"

1.77"

1.77"

1.77"

1.77"

1.77"

1.77"

F

1.85"

1.85"

2.76"

2.76"

2.76"

2.76"

2.76"

2.76"

2.76"

G

6.00"

6.00"

6.00"

6.00"

8.00"

8.00"

8.00"

8.00"

8.00"

P

IN/OUT

2" NPT

2" NPT

3" NPT

3" NPT

3" NPT

4" NPT

4" NPT

4" NPT

4" NPT

N

19.42"

23.84"

28.25"

28.25"

36.36"

39.35"

45.18"

54.00"

57.78"

M

25.98"

33.86"

40.54"

44.49"

44.49"

54.34"

52.37"

54.34"

54.34"

L

13.96

18.37"

22.78"

22.78"

30.89"

33.88"

39.70"

48.52"

52.30"

K

18.68"

26.56"

33.24"

37.19"

37.19"

47.04"

45.07"

47.04"

47.04"

J

18.01"

18.01"

22.76"

25.07"

25.95"

27.57"

28.01"

29.17"

29.17"

H

4.92"

9.34"

13.76"

13.76"

17.86"

20.86"

26.68"

35.50"

39.28"