MS-350 NP Operating Instructions Ver 3.01E

28

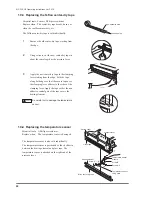

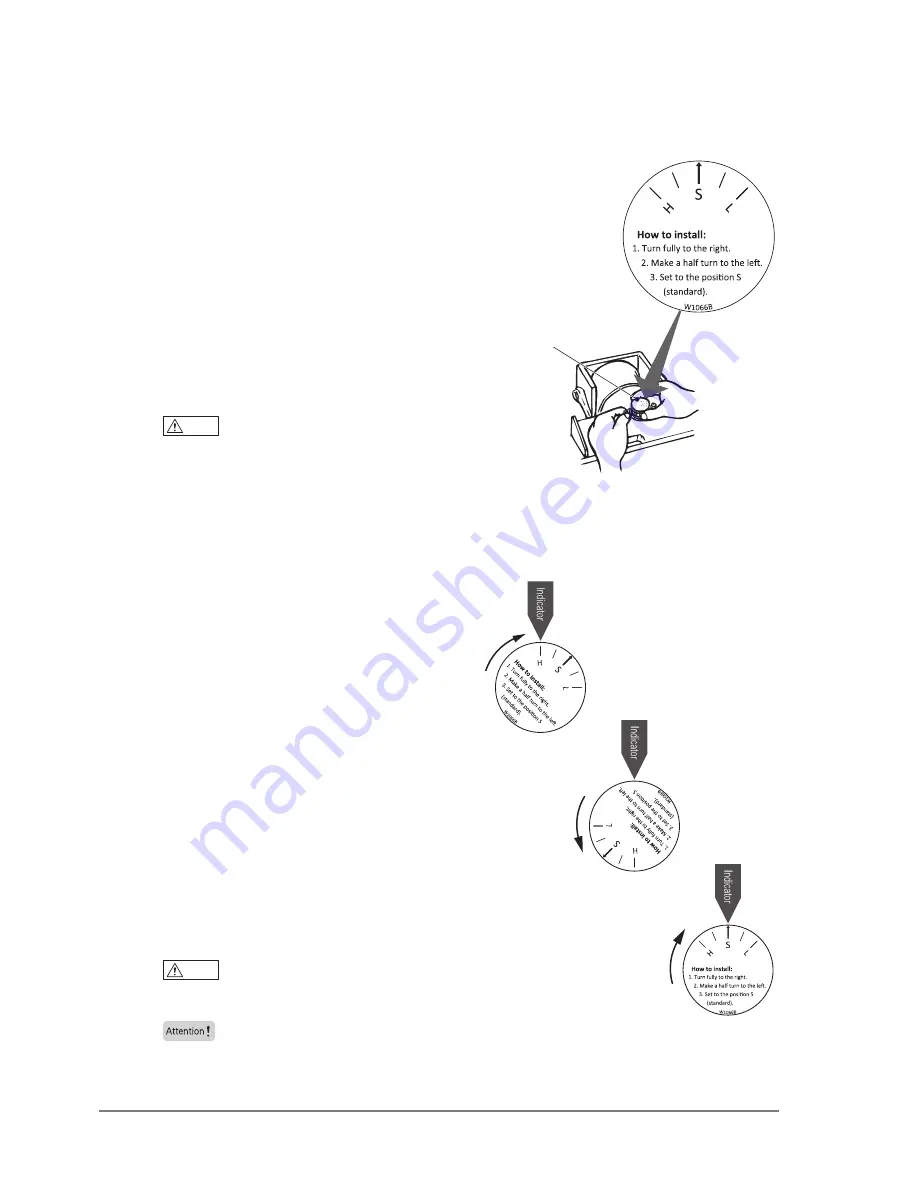

Seal pressure is adjusted at the time of factory shipment

so the optimum seal pressure can be achieved at the

position of S (standard). “H” on the lable indicates

“high”, and L is for “low”.

1

Remove a frame cover. Completely close seal

levers by pushing the upper lever with your

hand.

2

Install a pressure adjusting nut with shaft to the

hole and turn it clockwise until it stops. You will

have to turn it about 4 to 5 full turns.

Caution

If the pressure adjusting nut is not fully

screwed in, it may cause sealing failure or

cause the pressure lever to remain at the

lowered position due to the solenoid suction

strength dropping and the microswitch not

being activated.

3

The pressure adjusting nut will stop roughly at

the position of H as in the right illustration.

4

Then return the nut about a half turn

counterclockwise.

5

Again turn the nut clockwise and set it to the

position S (standard). Once the adjustment is

made, always use the securing screw to secure

the pressure adjusting nut.

11 Adjusting each part

11-1 Adjusting the seal pressure

Pressure adjusting nut

Caution

If the pressure is set excessively high (to the

direction of H), it will increase the sound of

the pressure lever movement.

Attention

If the pressure is set excessively high (to the

direction of H), a solenoid may make a

chattering noise. In that case, turn the

pressure adjusting nut to the direction of S.