●After the parts replacement is complete...

1

Close the pressure lever. With depressing the

lever, dial the pressure adjusting nut right to the

limit. Adjust the sealing pressure referring to

"11-1 Adjusting the seal pressure" and tighten

the fixing screw.

2

Return the control unit box to the initial

position.

3

Install the frame cover between the white plastic

nut and body frame, and fix the cover with the

nut.

10-1 Preparation

10-2 After the replacement

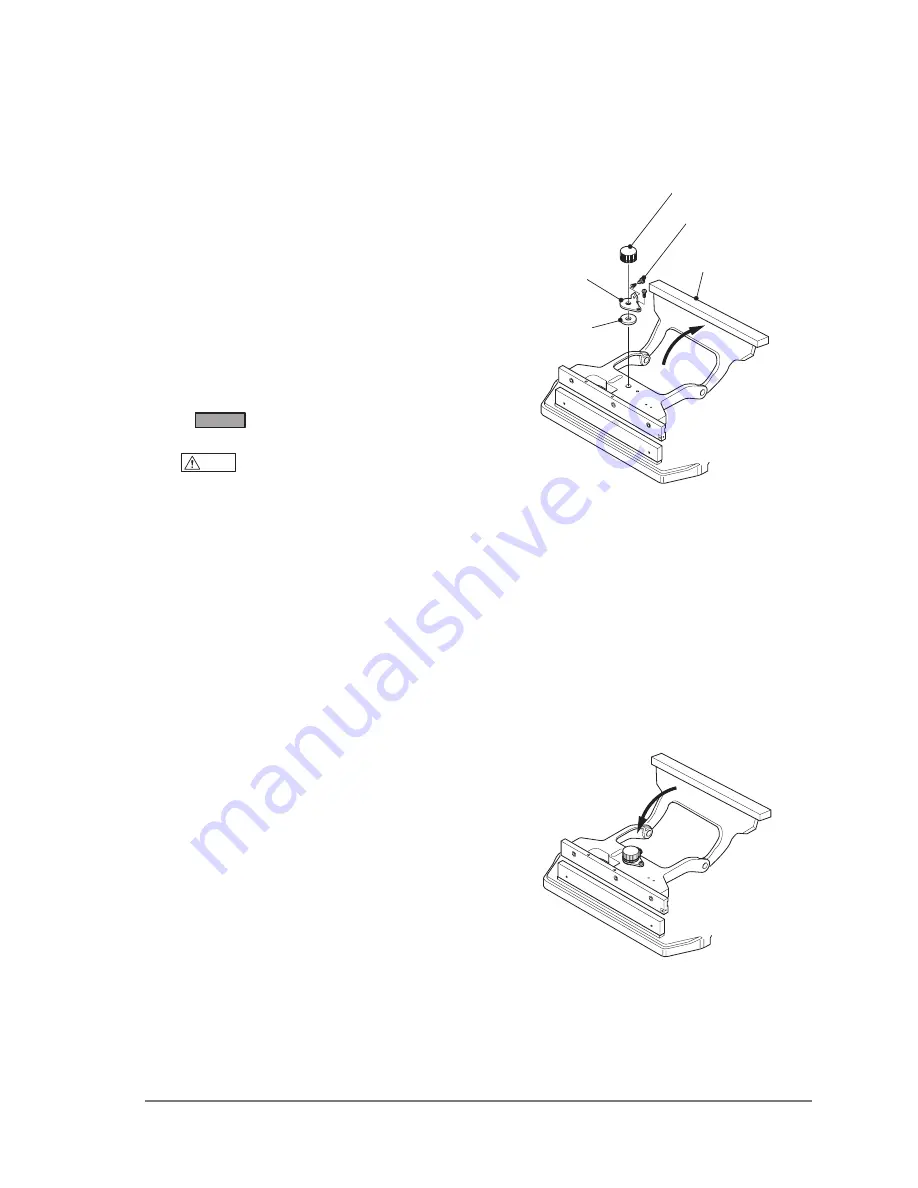

Small lever

Pressure adjusting nut

Pressure rubber

Pressure lever

Pressure adjusting nut

fastening screw

●Before replacing parts...

When replacing parts, lift up the pressure lever for

easier replacement.

How to lift up the pressure lever

1

Loosen the M5x10 frame cover fixing screws,

and remove the frame cover.

2

Loosen the pressure adjusting nut fastening

screw -do not completely remove it and turn the

nut counterclockwise to remove it. Now you can

remove the small lever and pressure rubber.

3

Remove the white screw and put down the

control unit base.

Please refer to “10-8 Replacing the control unit.”

When installing the pressure adjusting nut, please refer

to

Attention!

of “11-1 Adjusting the seal pressure.”

Warning

When the pressure lever is lifted up, you

can activate the microswitch by clicking it

with a thin stick, etc. Do not activate the

microswitch as it will start heating and

may result in fire if the plug is not

unplugged. Please refer to warning of

“10-9 Replacing the microswitch.)

MS-

350

NP Operating Instructions Ver

2

.

01

E

23