V-460/610 Series Operating Instructions Ver.2.04E

64

In order to maintain the machine in the proper operating condition, it is extremely important to carry out periodic

inspections and maintenance. Perform periodic maintenance as listed below.

Also, the below maintenance schedule is based on regular use of the machine. If the machine is used intensively or

in extreme conditions, maintenance should be performed at shorter intervals.

Daily maintenance

Seal area

Ensure that there is no visible damage to the seal area parts such as the center-dry tape

and silicone rubber.

$LU¿OWHU

5HPRYHD¿OWHUFXSDQGFOHDQLQVLGHWKH¿OWHU6HH³&OHDQLQJWKHDLU¿OWHU´

Weekly maintenance

Center-dry tape

Ensure that there is no damage or tarnishing of the center-dry tape.

Heating element

Ensure that there is no damage or tarnishing of the heating element.

Filter element

%ORZFRPSUHVVHGDLUWRUHPRYHWKHFORJJLQJRI¿OWHUHOHPHQW

6HH³&OHDQLQJWKH¿OWHUHOHPHQW´

Monthly maintenance

Glass tape

Ensure that there is no damage or tarnishing. If yes, replace the glass tape.

Sarcon sheet

Ensure that there is no damage or tarnishing. If yes, replace the Sarcon sheet.

Tubes for vacuum piping

※

1

Ensure that there is no foreign objects being stuck to the piping and/or elbows.

Annual maintenance

Silicone rubber

Ensure that there is no damage, burning, or crack. If yes, replace the silicone rubber.

Temperature sensor

※

2

Ensure that there is no damage or tarnishing of the temperature sensor.

Maintenance in every three years

Overhaul the machine and replace the below listed parts if any abnormality occurs.

Pneumatic parts

Solenoid valve and vacuum pump

Electrical parts

SSR-03 relay, circuit breaker, electrode, and microswitch

Others

1

Replacement of packing and sliding parts used for the machine will be required in about every three years. If the machine

is used intensively or in extreme conditions, maintenance should be performed at shorter intervals.

2

Pneumatic and electric parts need cleaning and replacement depending on the environment (dust, moisture, and

frequency of use).

※

1 Surrounding temperature and moisture in the air can cause discoloration and hardening of the tubes. If it happens, the tubes can break and cause air

leakage. Replace the tubes as necessary.

※

2

Van der Stahl Scientific

performs temperature calibration before the factory shipment; however, the actual temperature may gradually change

by

using the

machine. Calibrate the heating temperature periodically to use the machine in the optimum condition.

11 Maintenance

11-1 Maintenance schedule

Summary of Contents for V-460 Series

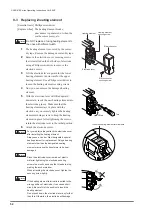

Page 61: ...V 460 610 Series Operating Instructions Ver 2 04E 61 ...

Page 66: ...V 460 610 Series Operating Instructions Ver 2 04E 66 12 Electric diagram 110V ...

Page 67: ...V 460 610 Series Operating Instructions Ver 2 04E 67 220V ...

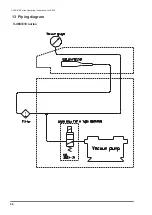

Page 68: ...V 460 610 Series Operating Instructions Ver 2 04E 68 13 Piping diagram V 460 610 series ...

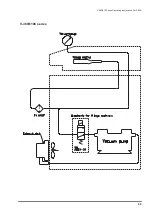

Page 69: ...V 460 610 Series Operating Instructions Ver 2 04E 69 V 460 610C series ...

Page 75: ...V 460 610 Series Operating Instructions Ver 2 04E 75 ...