-4

Detail G

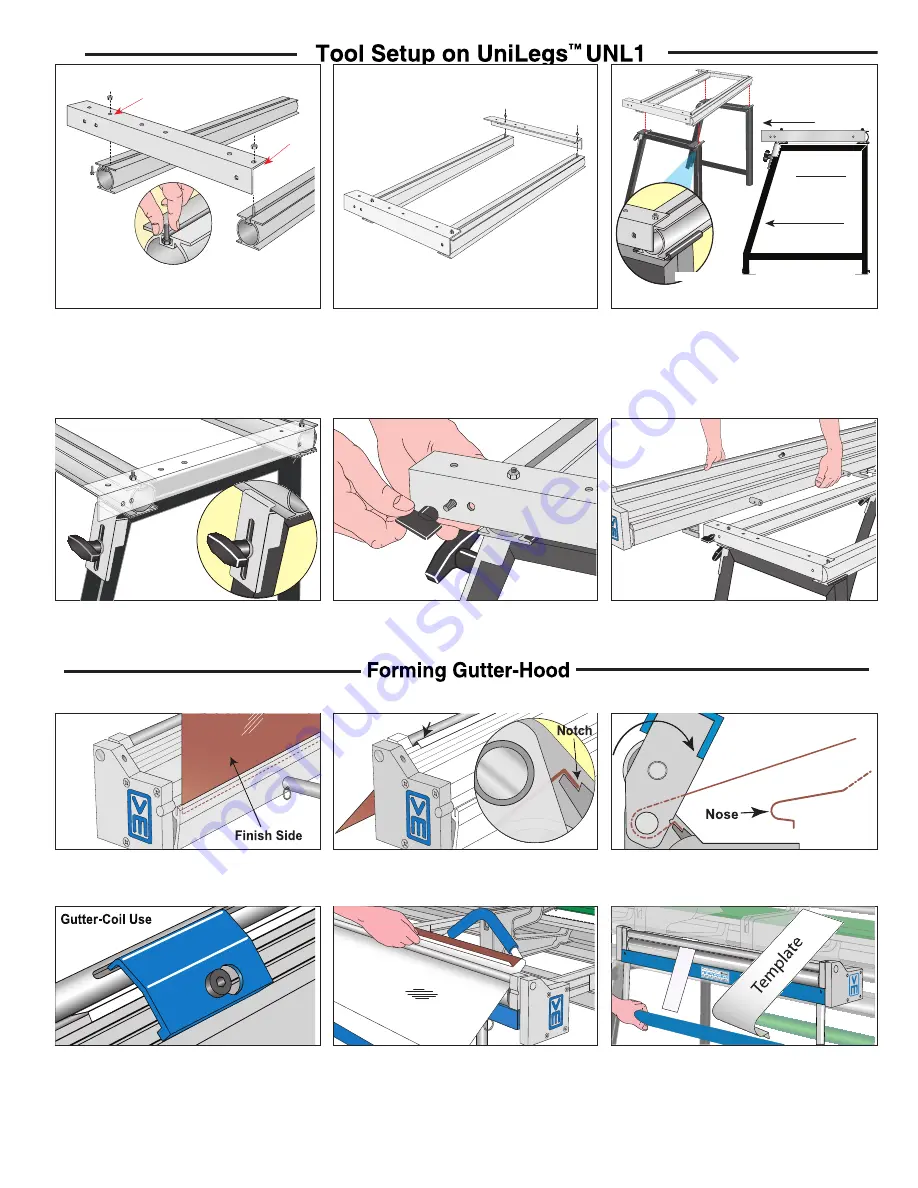

1

Lay out rails

L

as shown with screw tracks facing up. Insert

the hex head portion of screw

C

into each track (see Detail

G). With bracket

K

facing downward, align holes (indicated by

arrows), with hex head threads and lower into place. Tighten

bracket snugly against rails with locknuts

G

.

2

From opposite end of rails, again insert the hex head portion

of screw

D

into each track. Align holes in bracket

J

with hex

screw threads and lower into place. Install locknuts

H

. Square

up assembly and tighten all fasteners. Ensure all hole locations

match those in drawing before proceeding.

3

Position a UniLeg

™

at each end of rail assembly with the ex-

tended brackets facing the same direction as the leg flares

(see Side View). Align rail flanges with retainer hooks on top of

UniLegs

™

and slide into place (see Detail H). Note: Ask for help

holding UniLegs

™

apart during this step if needed.

Caution: To prevent the tool from tipping during use, always ensure the extended portion of the bracket is facing the same direction as the

leg flare (see step 3 above). Always situate tool on level ground

4

To finish installing the rail assembly, loosen each T knob and

extend latch plates up and over rail flange (see detail). Tight-

en T knobs snugly in place. Check T knobs often and tighten as

needed.

5

Insert a hex screw

C

through the outward hole of the extend-

ed portion of the bracket

K

. Start a knob

E

several threads

onto the hex screw

D

and leave loose for now. Repeat same pro-

cedure on opposite side of rail assembly.

6

Align slotted brackets on underside of tool to outside of ex-

tended brackets

K

and

J

. Align slots with hex screw threads

and slide in place to a complete stop. Tighten knobs

F

snugly.

Install handles referring to Steps 8 & 9 on Page 3.

Note:

General knowledge in the installation of gutters and/or roofing field will be very helpful in using these guidelines. Please take time to read this User Guide before getting

started. In this section, we will show how to form basic gutter-hood from standard trim coil.

1

Cut a blank up to 50 inches long and to the desired width.

Insert edge fully into slot with finish side (the side exposed

to the weather), facing as shown. Bend upward 90˚ to create a

1/2" flange.

2

With finish side of material facing downward, slide flat end

between roller and anvil until the 1/2" flange is fully seated

in notch. Note: The 1/2" flange must be exact to work properly

with brackets.

3

Lift roller handle to a complete stop to form the radius. Note:

When forming standard trim-coil, use of the reinforcement

clip (step 4), is unnecessary.

4

For gutter-coil, insert blank per Step 2 above and slide re-

inforcement clip in place. Lift roller handle to form radius

without allowing blank to touch or hit the clip which can cause

damage to material.

5

Return roller to the starting position and remove reinforce-

ment clip if in use. Rotate blank and slide from tool. Note:

Practice with smaller lengths until satisfied with results.

6

Cut a 3” or 4” strip and perform steps 1, 2 and 3 above. This

will become your template to use throughout the job and will

be further explained in the remaining steps.

Pre-Installation Note:

Most trim/gutter coil comes from the factory with a glossy, or shiny finish which can cause rain to overshoot the gutter opening (similar to water running off

a waxed car). This is a common occurrence in the gutter/leaf protection industry and should be discussed with the property owner. Normally, the gutter-hood loses it’s shiny finish after

a short time of exposure to the elements with the water then wrapping around the gutter-hood and falling into the gutter trough the way it’s supposed to. One solution, for those who

don’t want to wait for Mother Nature to do her thing, is to remove the shiny finish on the gutter-hood surface by lightly wiping it with a Scotch-Brite® type pad so it dulls the surface

slightly. This should allow the water to properly adhere to the gutter-hood until it is deposited into the gutter trough. Note: Scotch-Brite® is a registered trademark of the 3M corporation.

Detail H

Detail

Extended Bracket

Side View

Leg Flare

Rail Assembly