5000/10000 FLYWHEEL GRINDER

RADIUS CUTTER OPERATION (OPTIONAL)

Before grinding the flywheel or cutting a radius on a recessed flywheel, make certain

the flywheel is accurately centered. A dial indicator may be used. It is not necessary to

use coolant when using the radius cutter

1. On certain applications on a recessed or stepped flywheel such as International,

Mack, etc., it is necessary to remove the slight radius left by the grinding wheel.

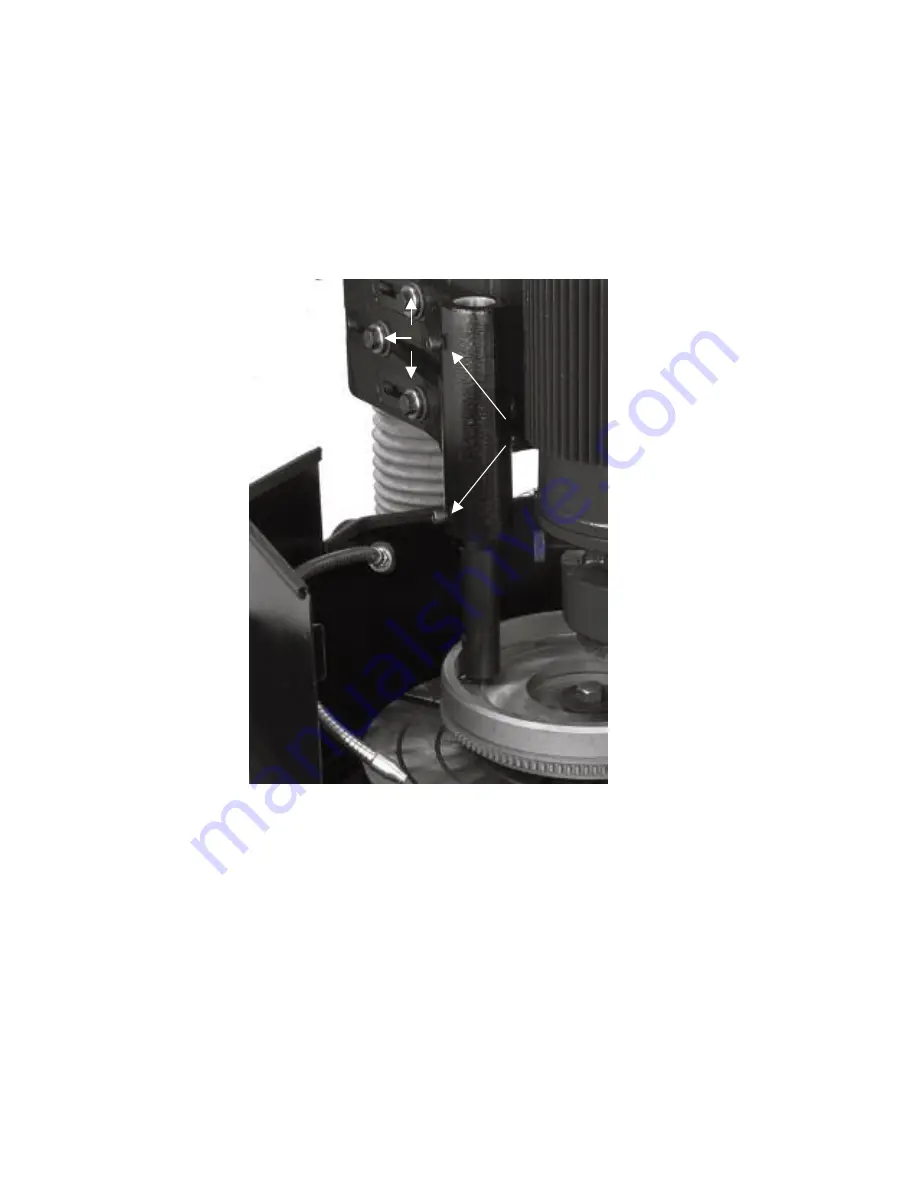

This can be accomplished using the optional Radius Cutter (Figure 26).

A

B

2. First, adjust the radius cutter assembly so the cutting tip of the tool bit is positioned

over the center of the table. This can be done by loosening the 3 hex bolts that

attach the radius cutter to the machine (Figure 26A) and sliding the assembly to the

front or back and retighten.

3. The tool bar may be positioned to the correct depth by loosening the 2 cap screws

(Figure 26B) and sliding the bar up or down and retighten. When properly

positioned, the grinding wheel will be about 1/2” above the highest point of the

flywheel when the tool bit is in contact with the radius to be removed. Do not over

extend the tool bar.

4. Loosen the column lock handle. Swing the grinding head to the left side of the

flywheel, so the tip of the tool bit is at its outermost location. Gradually feed the

grinding head down until the radius is removed.

Van Norman

30.

888-855-1789

Summary of Contents for FG10000

Page 2: ......

Page 4: ......

Page 11: ...5000 10000 FLYWHEEL GRINDER STANDARD EQUIPMENT FG5000 FG10 000 Van Norman 7 888 855 1789...

Page 21: ...5000 10000 FLYWHEEL GRINDER MACHINE DESCRIPTION Van Norman 17 888 855 1789...

Page 41: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 37 888 855 1789...

Page 42: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 38 888 855 1789...

Page 43: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 39 888 855 1789...

Page 44: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 40 888 855 1789...

Page 81: ......