5000/10000 FLYWHEEL GRINDER

GRINDING HEAD ADJUSTMENTS (continued)

3.

SIDE-TO-SIDE HEAD TILT ADJUSTMENT:

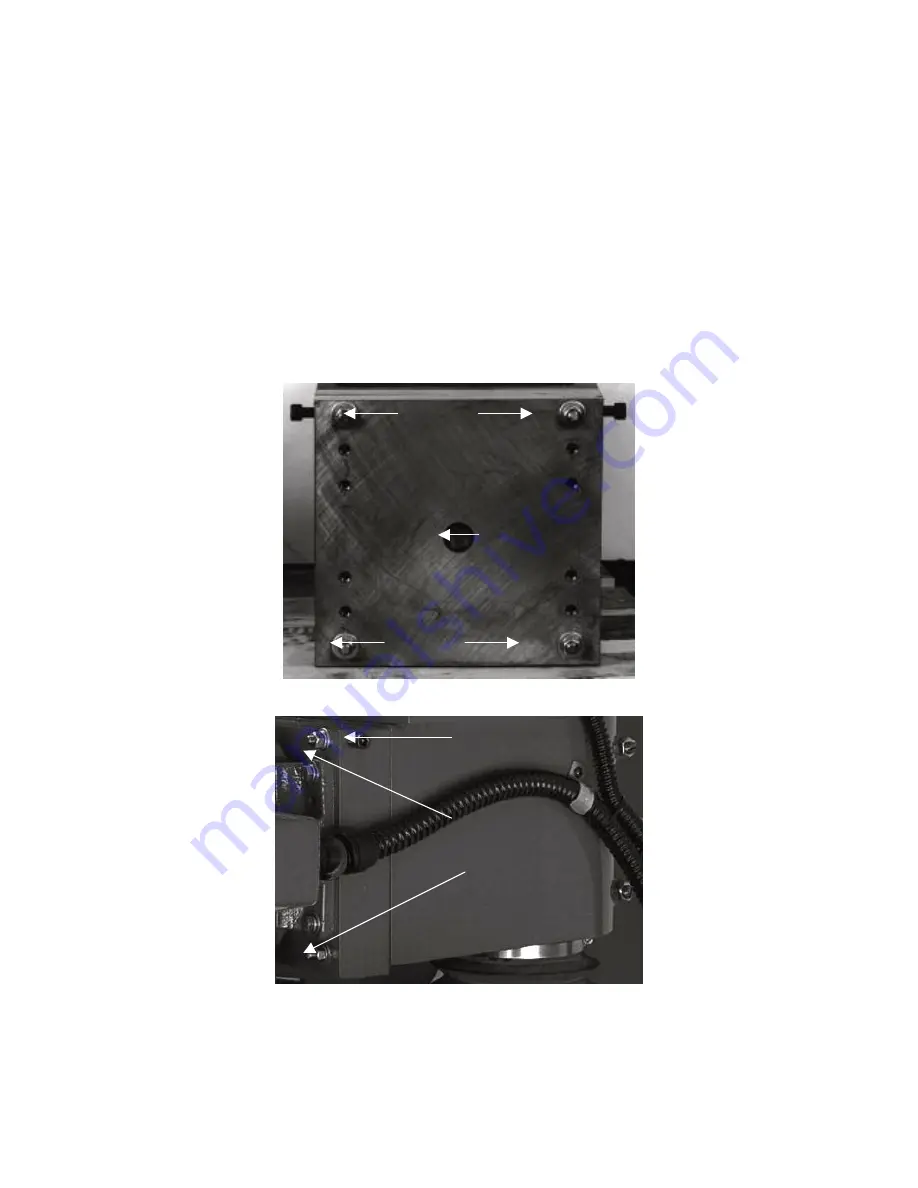

The grinding head is also adjustable for side-to-

side tilt. This adjustment will affect the flatness and/or parallelism of the ground work piece.

The double configuration used between the grinder motor and the cast iron motor flange

enables the motor to be mounted on the front plate, which pivots on a 1" dia. pin to allow

side-to-side adjustment (Figure 31). Adjustment may be made as follows:

a. Loosen four 3/8-16 nuts (9/16 Hex) approximately 1/2 to 3/4 turn.

b. Loosen adjusting screw on same side of machine as corresponds to the low side of the

grinding wheel. Tighten screw on opposite side to pivot adjusting plate appropriate

amount (Figure 32).

c. Check side-to-side tilt using same dial indicator setup used in checking front to rear tilt

above. The dial indicator reading should be identical when swung from one side to the

other.

Studs

Adjusting

Screws

Adjusting

Screws

Pivot Pin

Figure 31

Side to Side

Adjustment

Studs

Adjusting

Screws

Studs

Figure 32

Van Norman

34.

888-855-1789

Summary of Contents for FG5000

Page 2: ......

Page 4: ......

Page 11: ...5000 10000 FLYWHEEL GRINDER STANDARD EQUIPMENT FG5000 FG10 000 Van Norman 7 888 855 1789...

Page 21: ...5000 10000 FLYWHEEL GRINDER MACHINE DESCRIPTION Van Norman 17 888 855 1789...

Page 41: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 37 888 855 1789...

Page 42: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 38 888 855 1789...

Page 43: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 39 888 855 1789...

Page 44: ...5000 10000 FLYWHEEL GRINDER ASSEMBLY DRAWING Van Norman 40 888 855 1789...

Page 81: ......