AIR N ARC

®

150 SERIES

SECTION 6: TROUBLESHOOTING

090051-OP_r0 (FEB-2014)

PAGE - 41

Vanair Manufacturing, Inc.

vanair.com • 800-526-8817

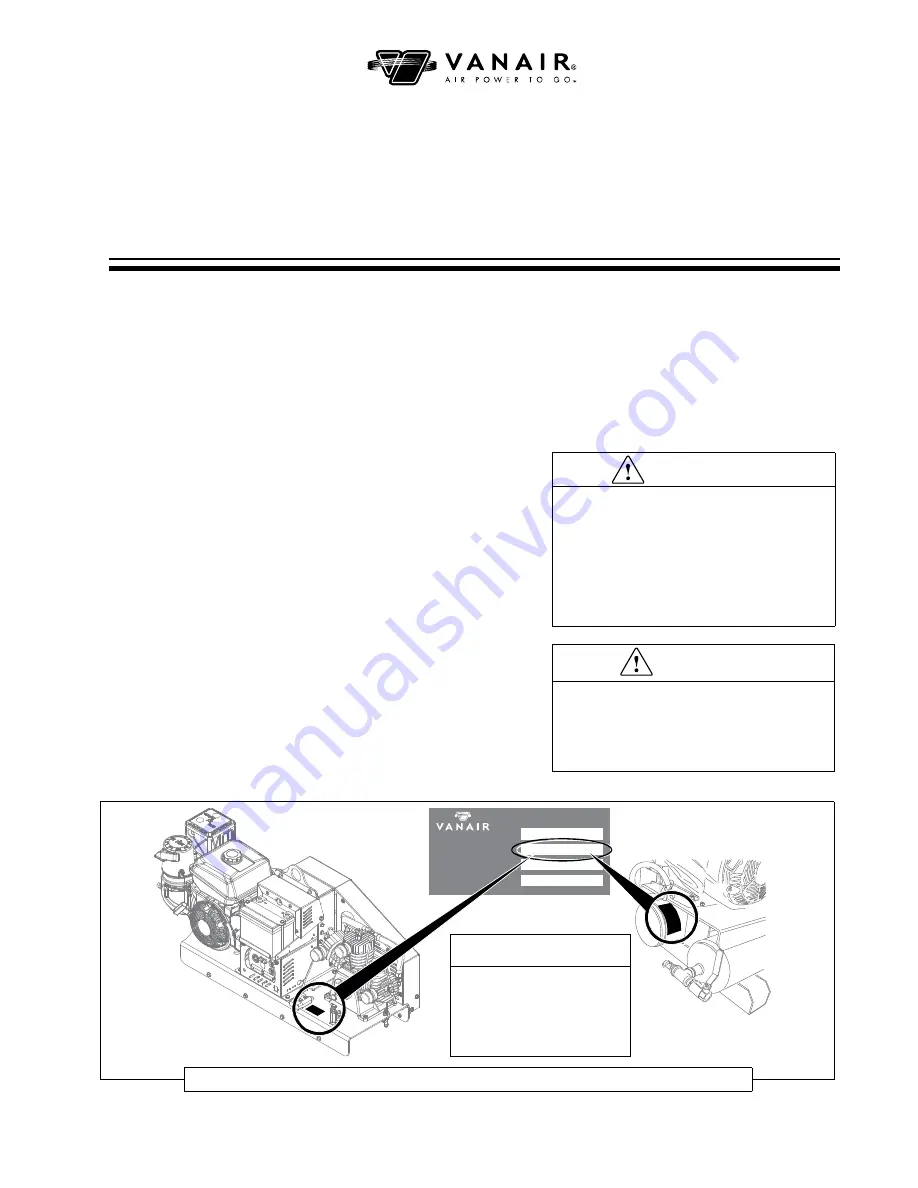

Figure 6-1: Machine Package Serial Number Plate Location

800-526-8817

PSIG

260940

MODEL NUMBER

SERIAL NUMBER

MAXIMUM PRE SSURE

COMPRESSOR INPUT RPM

www.vanai r.com

10-GALLON MACHINE

PLATE LOCATION

30-GALLON & SKID-MOUNT

MACHINE PLATE LOCATION

NOTE

When contacting the

Service Department,

please have machine

serial number on hand to

quickly expedite service.

6.1 GENERAL INFORMATION

The information contained in this section

has been compiled from years’ worth of

information gathered from the field. It

contains symptoms and usual causes for

the most common types of problems that

may occur. All available data concerning

the trouble should be systematically ana-

lyzed before undertaking any repairs or

component replacement.

A visual inspection is worth performing

for almost all problems and may avoid

unnecessary additional damage to the

machine. The procedures that can be

performed in the least amount of time

and with the least amount of removal or

disassembly of parts should be per-

formed first. Adherence to a routine

maintenance regimen will minimize the

occurrence of many common problems.

Refer to

Section 5.3, Maintenance

Schedule Table

for a typical mainte-

nance regimen program.

Although Vanair

®

strives to anticipate sit-

uations that may occur during the opera-

tion life of the machine package, the

Troubleshooting Guide

may not cover

all possible situations. Be aware that

additional troubleshooting information

may be found in other sources such as

the Engine Owner’s Manual. Should the

situation remain unresolved after

exhausting available sources, contact

your local dealer or the Vanair Service

Department.

WARNING

DO NOT operate any of the Air N Arc 150

Series machine’s functions if there is a

known unsafe condition. Disable the

equipment by disconnecting it from its

power source. Install a lock-out tag to

identify the equipment as inoperable to

other personnel to prevent accidental

application.

WARNING

Before starting, performing maintenance,

or replacing parts, relieve the entire

system pressure by opening the air tank

drain valve, which will vent all pressure

to the atmosphere.

SECTION 6:

TROUBLESHOOTING