AIR N ARC

®

150 SERIES

SECTION 6: TROUBLESHOOTING

090051-OP_r0 (FEB-2014)

PAGE - 49

Vanair Manufacturing, Inc.

vanair.com • 800-526-8817

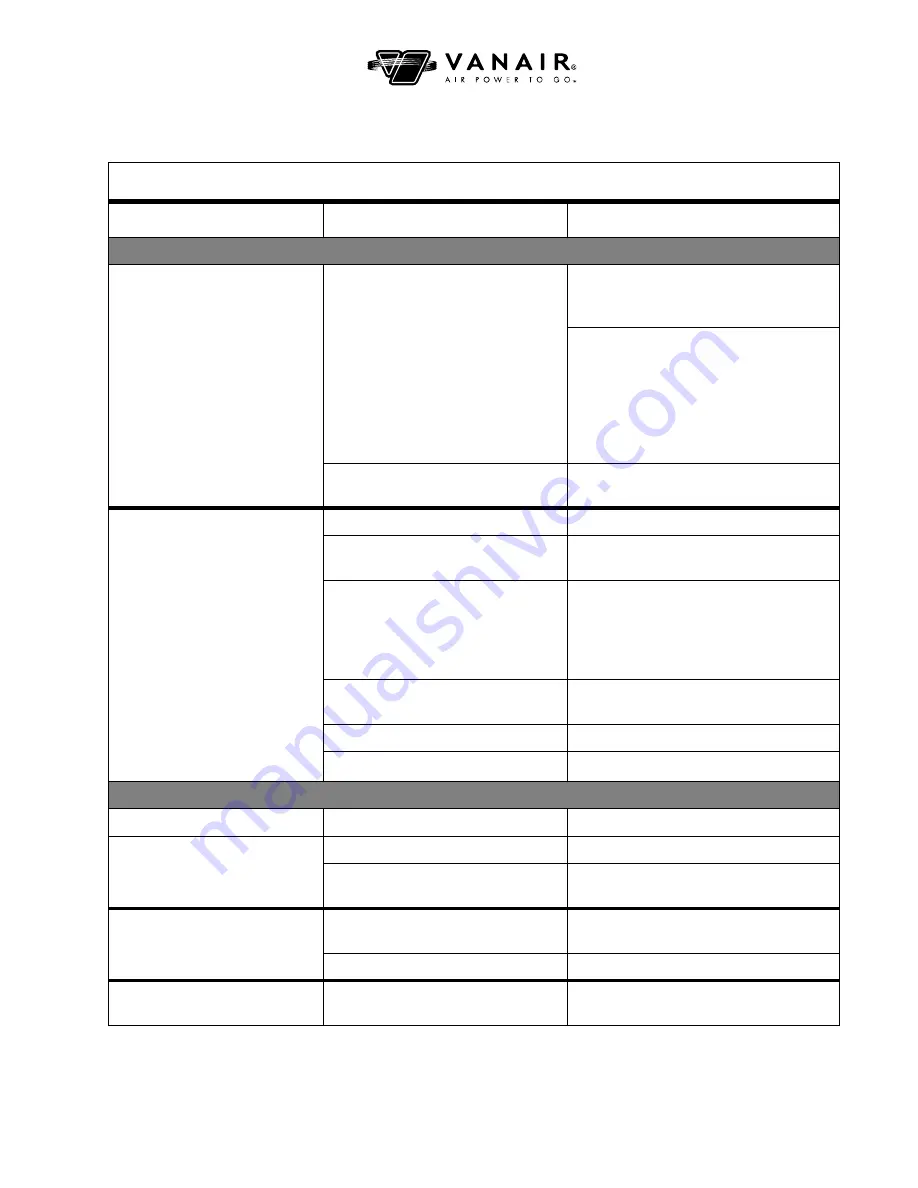

WELDER

Welder and/or battery charger

behave erratically

Connection cables or receptacles are

soiled/contaminated

Check for twisted cables and/or soiled/

contaminated or loose receptacle

connections.

Untwist and/or straighten out any suspected

cable tensions. Carefully wipe off any

contaminants to receptacle connectors

before re-connecting. Replace any worn or

damaged cables or receptacles. Contact the

Vanair Service Department if behavior

persists.

Welding function is not drawing enough

operating power

If running more than one function

simultaneously, turn off competing function.

No welder output

No power to welder

Press black power button on welder lead.

Incorrect battery voltage output

Check battery voltage for a minimum output

of 11 volts DC.

Serpentine belt out of position or

malfunctioning

Re-situate and adjust belt tension, or

replace belt if necessary. Consult

Section

5.5.2, Replacing and Re-tensioning the

Compressor and/or Generator Drive

Belts

.

Welder 6-pin connector not making

proper connection

Check welder 6-pin connector. Clean if

necessary.

Welder connections not solid

Inspect all welder connections.

Internal fuse blown in weld module

Contact the Vanair

®

Service Department.

AC GENERATOR

No AC generator output

Circuit breaker blown

Replace the circuit breaker.

Capacitor failure

Replace capacitor.

Loose or faulty wiring

Check wiring: Loose—secure;

faulty—replace.

Low AC voltage

Engine speed too low for demand

Adjust speed control. Refer to the Engine

Owner’s Manual.

Capacitor failure

Replace capacitor.

High AC voltage

Engine speed too high for demand

Adjust speed control. Refer to the Engine

Owner’s Manual.

6.2 TROUBLESHOOTING GUIDE

Fault/Malfunction

Possible Cause

Corrective Action