AIR N ARC

®

150 SERIES

SECTION 4: OPERATION

090051-OP_r0 (FEB-2014)

PAGE - 19

Vanair Manufacturing, Inc.

vanair.com • 800-526-8817

Vanair Manufacturing, Inc. recommends that

the following procedure is used for routine

shutdowns in order to keep the system in

optimal condition and minimimize undue

stress that may occur during the next start up

session if some of the machine conditions

were left in working mode(s) or had auxiliary

power draws left intact (such as a tool

receptacle left plugged into the generator,

etc.).

To prepare the machine for shutdown:

1. Shut off any tools or other items

that are drawing power from the

generator or compressed air from

the air tank.

2. Close all service valves.

3. Unplug any power cords that are

plugged into the generator panel.

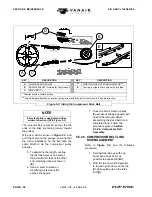

4. Turn the

Generator

and

Welder

switches on the control panel

(

Figure 4-2

, [

B

&

G

]) to their

OFF

positions.

5. Allow machine to run at idle for a 3-

5 minutes to allow for a cool down

sequence.

6. Turn the

Engine Control Switch

to

the

OFF

position [

A

1

]. If no air

leaks are present, the engine

should start at idle speed the next

time it is started.

4.3 ENGINE THROTTLE

CONTROL FUNCTIONS

The engine speed is controlled by three

factors:

1. The level of air pressure in the tank

and the position of the pilot valve

adjustment switch (refer to

Figure

4-3

).

2. The position of the welder switch on

the unit control panel, and the use

of the welder.

3. The position of the generator switch

on the control panel.

Consult Table 4A: Engine Throttle Control

Function

Conditions

to understand how the

engine speed relates to the demand(s) of the

machine system’s output functions.

NOTE

Refer to Engine Owner’s Manual for

additional information pertaining to the

starting of the engine.

TABLE 4A: ENGINE THROTTLE CONTROL FUNCTION CONDITIONS

I

Pressure Setting

Generator

Switch

Welder Switch

Engine Speed Condition Result

Tank Pressure Below (<)

100 PSI or Set Pressure

II

OFF

OFF

Engine runs at full throttle.

Tank Pressure Above (>)

100 PSI or Set Pressure

II

OFF

OFF

Engine runs at idle speed, ready for application.

OFF

ON

Welder can be activated by striking an arc (with engine

running at full throttle) and depressing button on

electrode holder.

ON

OFF

Engine runs at full throttle speed (3600 RPM);

generator is ready for use.

ON

ON

Full speed and all items available for use.

I

Any combination of the 150 Power System output functions (compressor, generator, welder) used simultaneously at

capacity will have an adverse affect on engine running at full throttle.

II

Factory set pressure: 95 PSI = ON / 125 PSI = OFF