AIR N ARC

®

150 SERIES

SECTION 5: MAINTENANCE

090051-OP_r0 (FEB-2014)

PAGE - 35

Vanair Manufacturing, Inc.

vanair.com • 800-526-8817

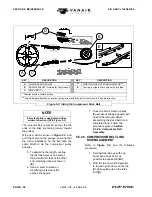

KEY

DESCRIPTION

KEY

DESCRIPTION

A

Rotate tab [

B

1

] 90° so that the tab’s end is parallel

to the slot it is linked to

D

Pull up on link end while pushing down on [

C

]

B

1

First tab to unlink

E

Rotate belt end with tab [

B

2

] 90° so that the tab’s

end is parallel to the slot it is linked to

B

2

Second tab to unlink

F

Push down on the tab [

B

2

], while pulling up on [

G

]

C

Push down on the tab [

B

1

], while pulling up on [

D

]

G

Pull up on link end while pushing down on [

C

]

Figure 5-4: Compressor Drive V-Belt - Link Removal

B

1

B

2

A

1

2

3

4

B

2

B

1

B

1

E

B

2

F

G

C

D

3. Rotate the belt end with tab [

B

2

]

so that the tab is turned parallel to

the slot.

4. Push down on the tab [

F

], while

pulling up on the link’s end [

G

].

5.5.2.6 COMPRESSOR BELT ASSEMBLY

Once the proper length of the belt has been

determined (refer to

Section 5.5.2.4

), and

the belt is shortened to its fitted length (refer

to

Section 5.5.2.5

), then the belt’s ends are

linked together to form the completed belt

loop. Refer to

Figure 5-5

, and the following

procedure:

1. Place tab [

A

] corner against the

inside of the link hole [

B

] (nearest

to thumb [

D

]).

2. With thumb [

C

], push on the tab’s

edge in the direction indicated.

3. Simultaneously with Step #2

above, push on link end [

B

] with

thumb [

D

] in the direction

indicated.

NOTE:

Inset [

E

] shows

how the pressure applied from

both thumbs causes the tab to

“rotate” toward the slot position.

4. When tab is positioned parallel

with the slot, push it/pull it

through the slot.

5. After the tab is through the slot,

twist it 90°, as shown in [

F

], to

secure it into place.

5.5.2.7 TRACKING COMPRESSOR BELT

ONTO PULLEY GROOVE

Refer to

Figure 5-6

and the following

procedure to mount the compressor link

drive belt onto the compressor and engine

pulleys.

1. Make certain that the belt is sized

correctly before setting it into

place on the pulleys. Consult