SECTION 7: ILLUSTRATED PARTS LIST

AIR N ARC

®

150 SERIES

PAGE - 80

090051-OP_r0 (FEB-2014)

Vanair Manufacturing, Inc.

vanair.com • 800-526-8817

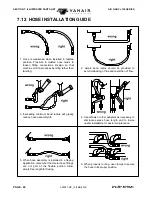

7.12 HOSE INSTALLATION GUIDE

1. Hose is weakened when installed in twisted

position. Pressure in twisted hose tends to

loosen fitting connections. Design so that

machine motion produces bending rather than

twisting.

2. Ample bend radius should be provided to

avoid collapsing of line and restriction of flow.

3. Exceeding minimum bend radius will greatly

reduce hose assembly life.

4. Use elbows or other adapters as necessary to

eliminate excess hose length and to insure

neater installation for easier maintenance.

5. When hose assembly is installed in a flexing

application, remember that metal hose fittings

are not part of the flexible portion. Allow

ample free length for flexing.

6. When properly routing, use clamps to secure

the hose in its proper position.