AIR N ARC

®

I

-

300 SERIES ALL-IN-ONE POWER SYSTEM

®

SECTION 5: MAINTENANCE

090045-OP_r1

PAGE - 51

Ensure that the traction side of the

drive belt [

G

1

] runs on the

inside

to

directly contact the drive pulleys [

H

,

B

,

M

,

N

,

K

and

J

] that run the

generators and hydraulic pump.

Also note that the drive belt tracks

on the inside of the clutch assembly

[

M

] (closest to the engine).

3. Replace the compressor serpentine

drive belt (refer to

Section 5.4.3.2

).

At this point the belts will need to be checked

for proper tension. Consult

Section

5.4.3.3

on how to re-tension the generator

serpentine belt, and

Section 5.4.3.1

to re-

tension the compressor serpentine belt.

5.4.3.5 RE-TENSIONING THE ENGINE

HYDRAULIC PUMP DRIVE BELTS

The hydraulic pump can only be accessed

when the machine’s maintenance access

panels are removed. Once the panels are

removed, consult

Figure 5-8

, and the

following procedure:

1. Make certain that the machine is off

and the ignition key removed.

2. Loosen, but do not remove, the three

(3) tensioner plate bolts [

D

]

mounting

the tensioner plate/pump sheave [

A

]

in place. Loosen only enough to allow

tensioner plate to pivot along the

grooves in the plate while still

remaining in position.

3. Use a 1/2” drive torque wrench applied

to the square tensioning hole [

E

] to

manually rotate the plate/pump

sheave about the loosened, but

anchored, mounting bolt (bottom bolt).

Apply torque of 51 in-lbs. as per

Table

5B: Measuring Belt Deflection

for

the proper tension measurement.

4. Once a position is achieved that

accounts for a satisfactory tension in

the belt, torque the three (3) tensioner

plate bolts [

D

] to 12 ft-lbs. (16.3 Nm) to

secure the tensioner into position.

5.4.4 SERVICING THE SYSTEM FUSES

AND CIRCUIT BREAKERS

Consult

Figure 5-9

for the location of the DC

welder generator fuse, and

Figure 5-10

to

determine the location of the engine and

generator breakers.

Figure 5-11

gives the

locations of the Power System fuses.

NOTE

Vanair

®

recommends that the air

compressor and generator/ hydraulic

pump drive belts both be changed at the

same time even if only one of the belts is

in need of being changed.

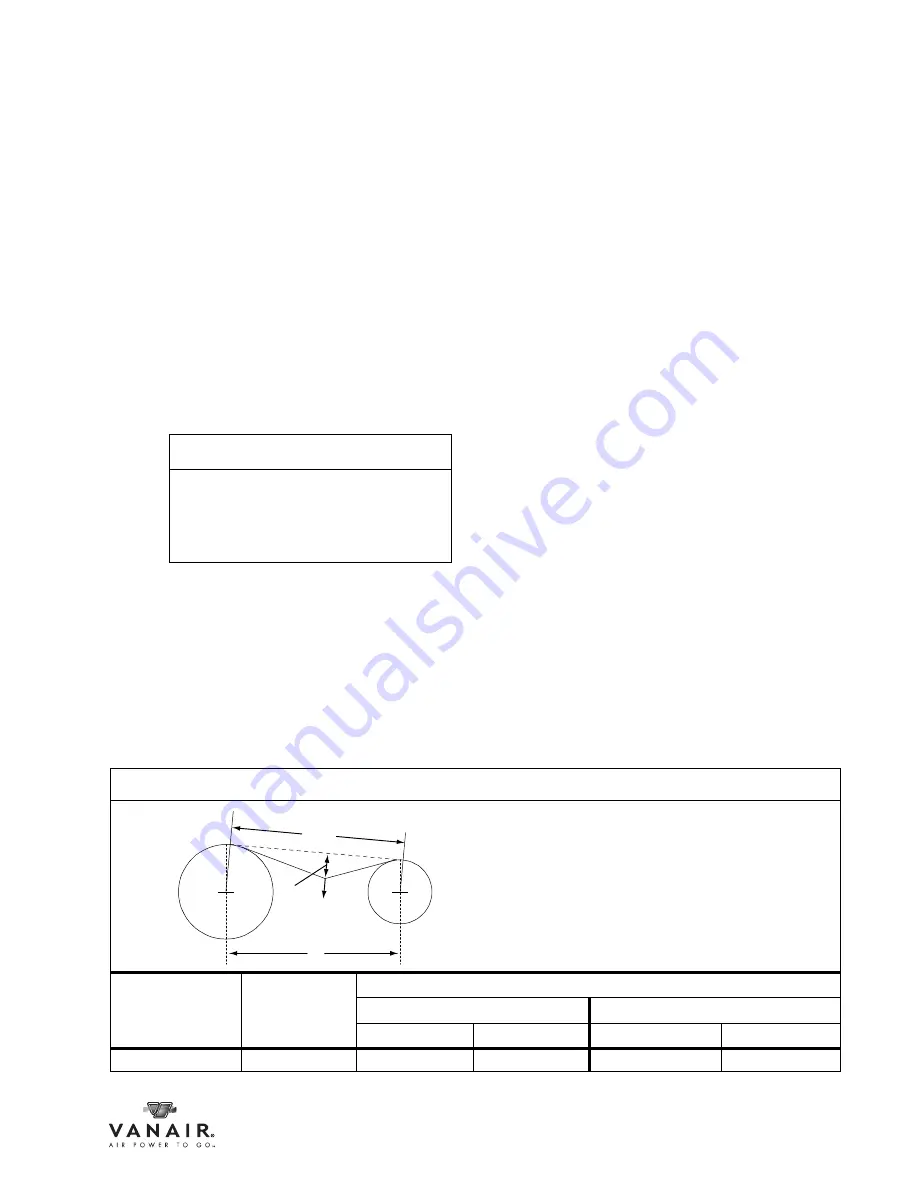

TABLE 5B: MEASURING BELT DEFLECTION (All measurements given are estimations)

SPAN LENGTH (in)

DEFLECTION

DISTANCE (in)

DEFLECTION FORCE (lbs)

ALL RIBS

TORQUE TO IN-LB TENSION

RE-TENSION

NEW INSTALL

RE-TENSION

NEW INSTALL

17.91

0.25

12.000

18.5

53

81

P

F

c

q

P - Span Length

c - Center Distance

F - Deflection Force

q - Deflection Distance

Summary of Contents for AIR N ARC I 300 SERIES

Page 12: ...PAGE X 090045 OP_r1 BLANK PAGE ...

Page 129: ...BLANK PAGE ...