VIPER DIESEL

SECTION 5: MAINTENANCE

090058-OP_r0 (AUGUST-2014)

PAGE - 19

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

Co

ntinu

e

d on ne

xt pa

ge

7

Che

c

k rad

iator hoses and

cla

m

p

ban

ds

•

I

Ensure

that

t

he

radi

at

or h

o

ses

an

d

clamp

b

ands

are

in

ta

ct

, in

g

ood workin

g

o

rder

a

nd fa

ste

ned correct

ly

. I

f

ho

ses are showi

ng si

gns of

wear (cracki

ng,

stret

c

hi

ng

,

et

c.

), repl

ace ho

ses (re

fer t

o

Secti

o

n 7

.14

,

Hose

In

st

al

la

ti

on

Gu

id

e

fo

r

a

ssi

sta

n

ce when repl

aci

ng

da

maged

ho

ses).

8

Rep

lace fuel filter ele

m

e

n

t

•

Cons

ult

th

e

Engi

ne Opera

tor

’s

Manua

l fo

r

pro

c

edure on

rep

laci

ng t

he eng

ine

f

uel

f

ilt

er

e

le

m

ent

. Refe

r t

o

Tab

le

7A: Re

comme

nded Spare Pa

rts List

fo

r

repl

ace

m

ent

ki

t or

part

o

rd

e

r n

u

mber.

9

Flush cooling system

•

Cons

ult

th

e

Engi

ne Opera

tor

’s

Manua

l fo

r

pro

c

edure on

cl

ean

ing

t

he

radi

at

or wat

e

r

jac

k

et

.

10

Rep

lace fan bel

t

•

Cons

ult

th

e

Engi

ne Opera

tor

’s

Manua

l fo

r

pro

c

edure on

rep

laci

ng t

he eng

ine

f

an bel

t.

Refe

r t

o

Tab

le

7A:

Recommended Spa

re

Parts

Li

st

f

o

r re

pla

c

emen

t kit

or

pa

rt order numbe

r.

11

Rep

lace ai

r filter ele

m

e

n

t

Cons

ult

th

e

Engi

ne Opera

tor

’s

Manua

l fo

r

pro

c

edure on

ch

angi

ng t

he engi

ne ai

r

fi

lt

er. Ref

e

r

to

T

a

bl

e 7A

:

Recommended Spa

re

Parts

Li

st

f

o

r re

pla

c

emen

t kit

or

pa

rt order numbe

r.

I

Every 200 ho

urs

o

r six (6) mo

nths.

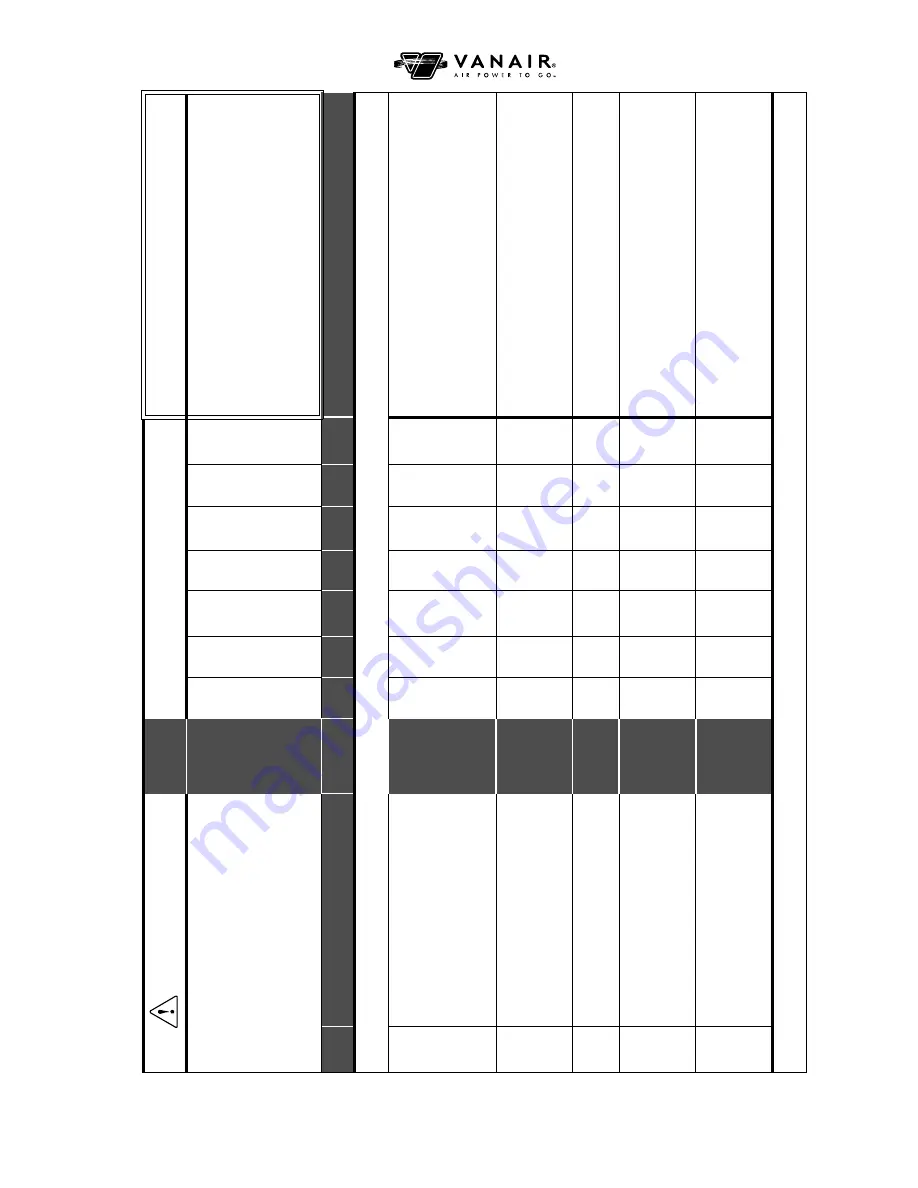

5.3B MAINTENANCE SCHEDULE

T

A

BLE - ENGINE INTER

V

ALS

WARNING

B

R

E

AK-IN

PE

R

IOD

MAINTE

NANCE SCHEDULE

NOTE

B

e

fo

re

p

e

rfo

rmi

ng

m

a

in

ten

a

nc

e:

Shu

t d

o

wn

ma

chin

e, re

liev

e

all

sy

stem p

re

ssu

re

and

loc

k

o

u

t a

ll p

o

wer

,

a

s

pe

r the

Sa

fe

ty

Sec

ti

on

of th

is

ma

nu

al

.

Fo

r lo

ck

-o

u

t/

tag

-o

ut d

isc

on

ne

ct

th

e

negative (-

) battery cable.

Firs

t 50

Ho

urs

Daily

Every 50

Ho

urs

Every 1

00 Hou

rs

or One (1) Year

Every 2

00 Hou

rs

Every 4

00 Hou

rs

Every 5

00 Hou

rs

Every two (2)

years

If wor

k

ing

in

du

sty

or d

irty co

nd

itio

ns, re

du

ce th

e

re

c

o

m

m

e

nd

ed

ti

me

i

n

te

rv

al

s

be

twe

e

n

se

rv

ic

ing

b

y

ha

lf for en

gin

e

and

com

p

re

sso

r oil ch

an

ge,

and

eng

ine an

d co

mp

ress

or

filter

s

e

rv

icin

g.

KEY

TASK DESCRIPTION

ACTION TO

TAKE