SECTION 4: OPERATION

VIPER DIESEL

PAGE - 12

090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

8. After the initial run, shut down machine

allow it to depressurize and top off

compressor oil sump, as required.

Inspect for any leaks, and tighten any

loose fittings.

4.4 SHUTDOWN PROCEDURE

1. Allow engine to run at idle for

approximately sixty (60) seconds.

2. Press the STOP button; NOTE: Allow the

compressor to blow down prior to re-

starting.

4.5 SUBSEQUENT START-UP

PROCEDURE

On subsequent starts, follow the procedure

explained below:

1. Check engine and compressor oils

and add oil, if necessary.

2. Fill the fuel tank.

3. Press and hold Start button for one (1)

second to turn on display.

4. Press and hold Start button a second

time for one (1) second to start Engine

cranking sequence.

5. Allow the machine to warm up

sufficiently before operating.

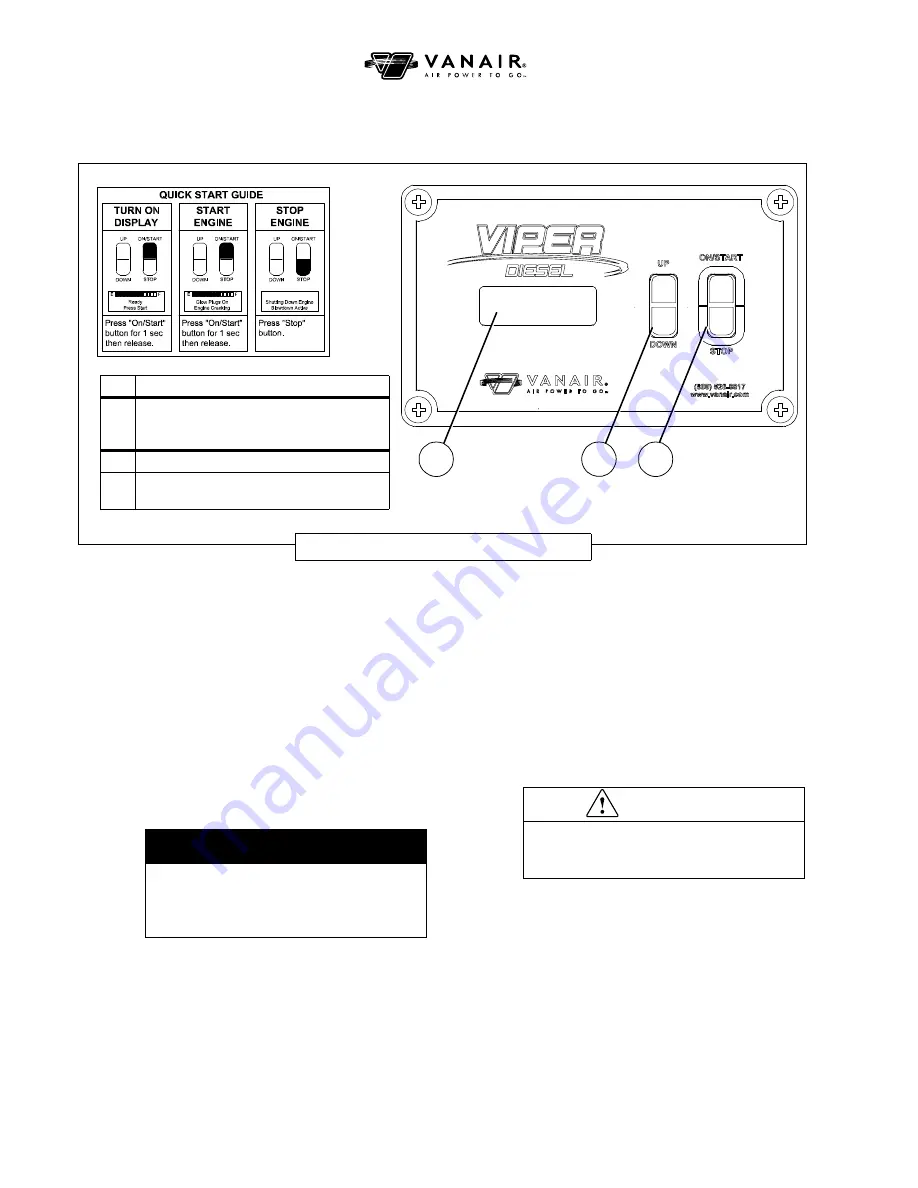

4.6 CONTROLLER GUIDE

Refer to

Figure 4-2

for controller panel

display features. The electronic controller

supplied in the Diesel Viper package has

been designed to work in conjunction with

the linear actuator that operates the speed

control. When used properly, they will reduce

fuel consumption, remind the user when

periodic service is due, extend the useful life

IMPORTANT

In case of emergency where immediate

shutdown is required, this procedure is

not necessary.

Press the STOP button immediately.

WARNING

Engage stop button prior to opening

panel or servicing machine. Engine can

start at any time in Auto mode.

Figure 4-2: Controller Panel

A

B

C

KEY

DESCRIPTION

A

INSTRUMENT PANEL MODULAR DIS-

PLAY SCREEN: Display contains four lines,

20 characters/line.

B

SCROLL SELECTOR ROCKER SWITCH

C

ON/START

AND

STOP

SELECTION

ROCKER SWITCH