VIPER DIESEL

SECTION 5: MAINTENANCE

090058-OP_r0 (AUGUST-2014)

PAGE - 15

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

5.1 GENERAL INFORMATION

A strict maintenance program is the key to

long life for the Viper Series Compressor

System package. Below is a program that,

when adhered to, should keep the package

in top operating condition. Refer to

Table

5.3A

,

Table 5.3B

, and

Section 5.5, Parts

Replacement and Adjustment Procedures

for detailed descriptions of specific

compressor system components. Refer to

Table 7A

in

Section 7

for part order

information.

5.2 ROUTINE MAINTENANCE

SCHEDULE

Vanair

®

Manufacturing, Inc. considers the

maintenance schedule given in

Section 5.3,

Maintenance Schedule Table (5.3A for

compressor; 5.3B for engine)

, to be part of

the warranty agreement with the customer.

This maintenance regimen must be followed

in order to protect the warranty of the

machine package.

WARNING

To avoid accidental system start-ups

during periods of maintenance,

disconnect the positive (+) cable to the

battery terminal, and place the wire

aside, or tape the contact end so that it

cannot accidentally contact the battery

post.

NOTE

Operating the machine package in a

severe environment requires more

frequent service intervals.

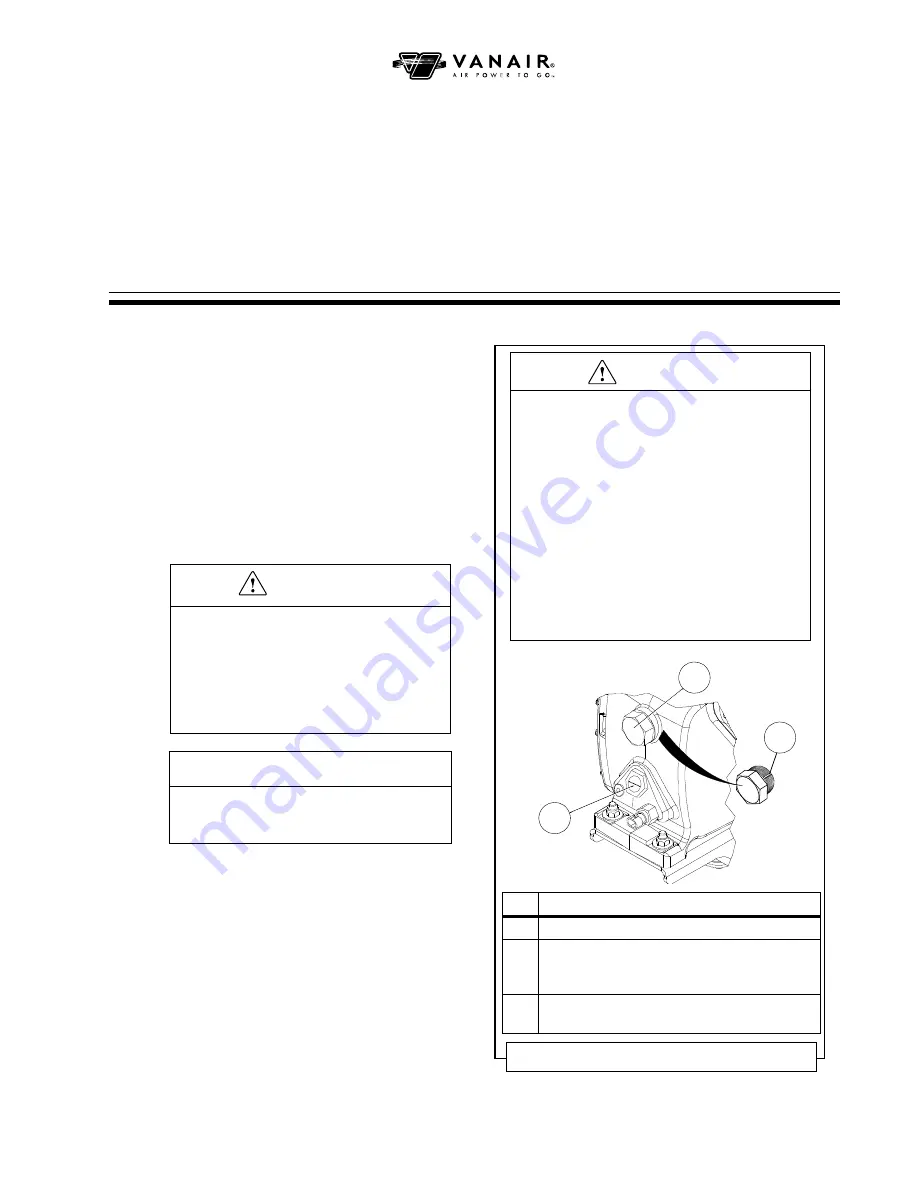

KEY

DESCRIPTION

A

COMPRESSOR FILL CAP

B

FILL CAP BLEED VENT GROOVE: Open/crack

cap slightly to allow bleed vent to relieve air

pressure before removing cap.

C

OIL FILL LEVEL: Full indication is the center of

the sight glass.

Figure 5-1: Compressor Pressure Relief Check

A

B

C

WARNING

DO NOT remove caps, plugs and/or other

components when compressor is running or

pressurized. Stop compressor and de-

pressurize system prior to maintenance of

system. Relieve the entire system pressure

by opening the air tank drain/vent valve, if

equipped, which will vent all pressure to the

atmosphere.

Wear personal protective equipment such as

gloves, work boots, and eye and hearing

protection as required for the task at hand.

Refer to

Figure 5-1

. Open fill cap SLOWLY

(contents under pressure) to make sure all

pressure has been relieved.

SECTION 5:

MAINTENANCE