9

T

RANSITIONING

TO

6-

IN

.

DUCTS

(

FOR

110, 130

AND

150

CFM

UNITS

ONLY

)

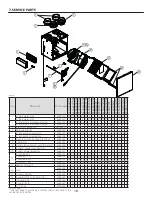

If using 6-in. ducts, install 5-in. to 6-in. transitions on the ports, and secure using duct tape only. If rigid ducting is used,

install a 12-in. section of

fl

exible duct between the transition and the rigid ducting (see above).

R

IGID

DUCTS

To prevent potential water leakage in cold side rigid ducting insulation, seal all rigid ducting joints with duct tape.

To avoid transmission of vibrations, always use a 12-inch section of

fl

exible duct to connect rigid ducts to the unit. To

connect insulated rigid ducts to the unit (cold side) using insulated

fl

exible ducts, follow instructions in section 2.5. To

connect regular rigid ducts (warm side) to the unit using non-insulated

fl

exible ducts, use a tie wrap.

2.6 C

ONNECTING

THE

D

UCTS

TO

THE

U

NIT

I

NSULATED

FLEXIBLE

DUCTS

Use the following procedure to connect the insulated

fl

exible ducts to the ports of the unit (exhaust to outside and fresh

air from outside).

1. Expose the

fl

exible duct by pulling back the insulation, and place it

over

the inner port ring.

2. Attach the

fl

exible duct to the port using a tie wrap.

3. Seal the joint using duct tape.

4. Pull the insulation and vapor barrier over the joint, tuck them

between the inner and outer rings

of the double collar and

fasten them in place using duct tape.

VJ0157

•

If ducts have to go through an unconditioned space (e.g.: attic), always use insulated ducts to prevent

condensation formation inside and outside ducts, which could cause material damage and/or mold growth.

•

Do not use screws to connect the ducts or transitions to the ports so as not to interfere with ports

inner dampers operation. A non-functioning damper could freeze the unit, which could cause damages.

CAUTION

The vapor barrier should remain intact and free of cracks or openings. An opening could produce condensation

inside or outside duct, which could cause material damage and/or mold growth in the long run.

CAUTION

2.5 I

NSTALLING

THE

E

XTERIOR

H

OODS

To avoid cross-contamination:

• Keep at least 6 feet between both hoods OR use approved combined

hoods model 14690.

• Install hood(s) at least at 18 inches away from the ground OR depth of

expected snow accumulation, whichever is greater.

Refer to illustration above for proper connection

method of the insulated ducts to the hoods.

“Anti-Gust Hoods” should be installed in regions

where a lot of snow is expected to fall.

VD0028

E

XHAUST

H

OOD

*

I

NTAKE

H

OOD

18”

18”

6’

6’

18”

O

PTIONAL

DUCT

LOCATION

T

APE

AND

DUCT

TIE

C

AULKING

Make sure intake hood is at least 6 feet (1.8 m) away from any

of the following:

• Dryer exhaust, high ef

fi

ciency central forced-air system vent,

central vacuum vent

• Gas meter exhaust, gas barbecue-grill

• Any exhaust from a combustion source

• Garbage bin and any other source of contamination.

Ignoring these recommendations could signi

fi

cantly degrade the

quality of the incoming air which, in some cases, could result in

health consequences.

In the event of a con

fl

ict between our conditions and local

requirements, the latter will have priority.

WARNING

!

NOTE: It is recommended to use 6" ducting instead of 5" ducting for 150H75NT, 150H75NS, 150E75NT and 150E75NS

units if required air

fl

ow is over 130 CFM. It will prevent having too high static pressure in the ducting.

C

AULKING

*Do not install exhaust hood with non-return

damper since it can freeze in winter.