ATO-

250™ Operating Procedures

4

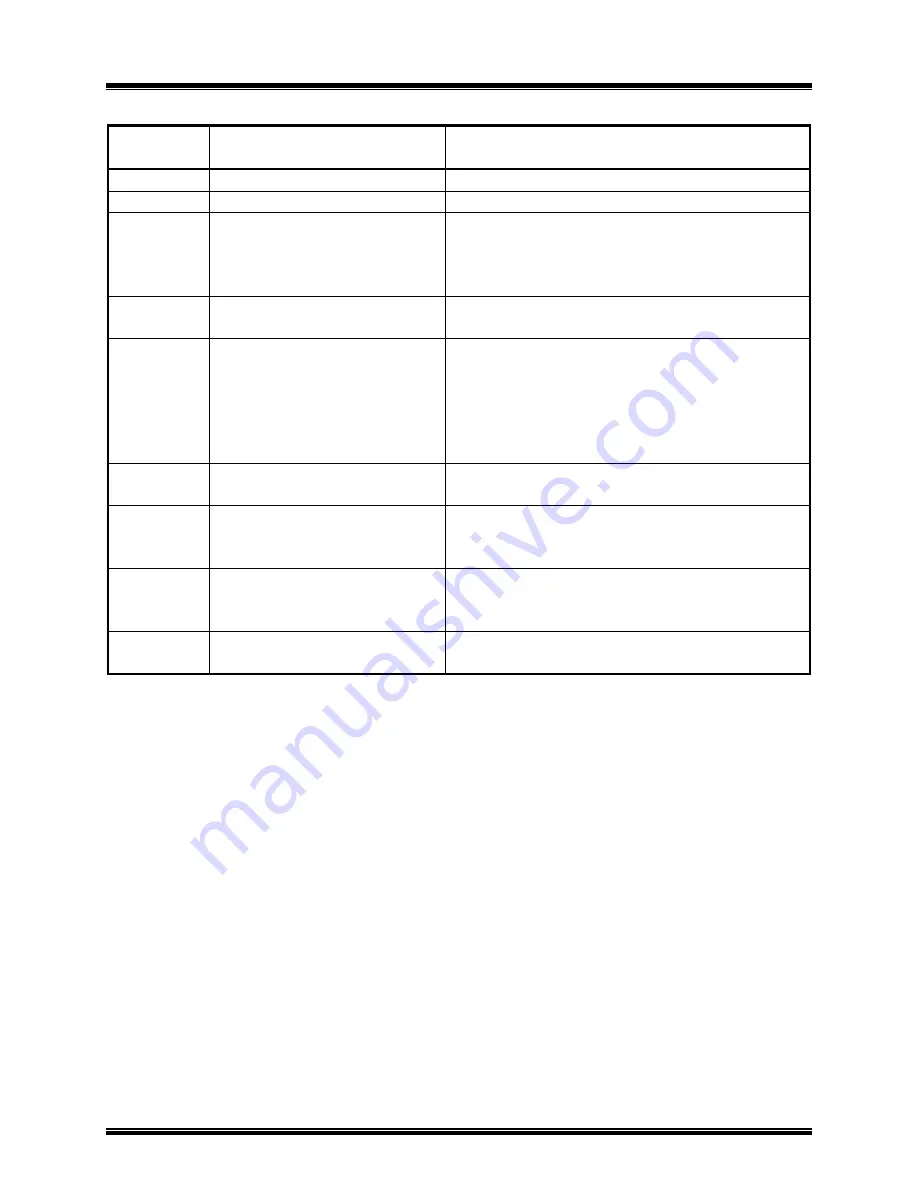

Table 2.0 Functional Description of Controls and Indicators

Fig. 1

Index #

Adjacent Panel Marking

Functional Description

1

None (typical at 2 places)

Red, voltage-sensing, input jacks.

2

None (typical at 2 places)

Red, test-current, output jacks.

3

HIGH CURRENT

PRESENT

Red, indicator LED. This is to warn operators

of the presence of high current, which can

“kick” high voltage if the current lead is

disconnected.

4

120/240 Vac, 8A, 50-60Hz

I/O

Input power connector with third wire safety

ground and 10A built-in circuit breaker.

5

RS-232C

9-pin, female, DB type, serial interface-port

connector.

PIN

SIGNAL

2 Rx

3 Tx

5 Signal Gnd

6

CURRENT

CONTROL

Rotary knob used for adjusting test-current

level from 10 to 250 Amperes.

7

None

4-line by 20-character, backlit, LCD screen.

Use for displaying menu selections, prompts

and test-result data.

8

None

Keypad consisting of momentary-contact

pushbuttons. Ten alphanumeric keys and six

function keys.

9

None

Built-in thermal printer for outputting test result

data on 2.5 inch wide thermal paper.

6.1 ATO-250 LCD Contrast Control

To darken the LCD screen, press and hold

the “Paper

Contrast” switch for two

seconds. To lighten the LCD screen, press

and hold the “Paper

Contrast” switch for

two seconds.

6.2 ATO-250 Printer Control

To advance the printer paper, press “Paper

Contrast” switch once. Paper will advance

from printer. Press “Paper

Contrast”

switch once, paper will advance backward

from printer.

6.3 RS-232C Computer-Interface port

A Windows based software package is

supplied with each ATO-250, which allows

the user to retrieve test records stored in the

ATO-250 memory.