2

BEFORE OPERATING ENGINE

•

Read entire Operating & Maintenance Instructions AND the

instructions for the equipment this engine powers.*

•

Failure to follow instructions could result in serious injury or

death.

THE OPERATING & MAINTENANCE INSTRUCTIONS

CONTAIN SAFETY INFORMATION TO

•

Make you aware of hazards associated with engines

•

Inform you of the risk of injury associated with those hazards, and

•

Tell you how to avoid or reduce the risk of injury.

The safety alert symbol

(

)

is used to identify safety

information about hazards that can result in personal injury.

A signal word (DANGER, WARNING, or CAUTION) is used

with the alert symbol to indicate the likelihood and the

potential severity of injury. In addition, a hazard symbol may

be used to represent the type of hazard.

DANGER

indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING

indicates a hazard which, if not

avoided,

could result in death or serious injury.

CAUTION

indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION

,

when used

without

the alert symbol,

indicates a situation that

could result in damage to

the engine.

WARNING

The engine exhaust from this product

contains chemicals known to the

State of California to cause cancer,

birth defects, or other reproductive

harm.

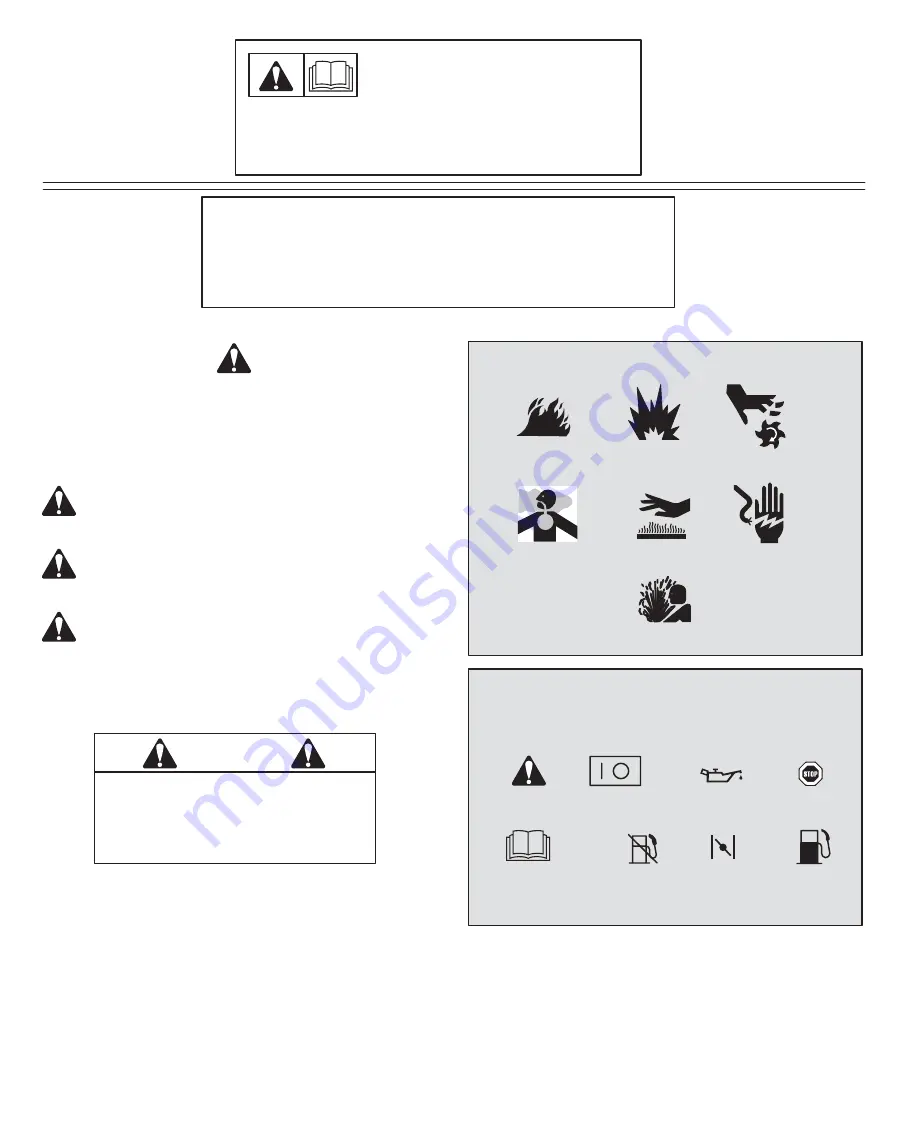

HAZARD SYMBOLS AND MEANINGS

Explosion

Toxic Fumes

Moving Parts

Shock

Hot Surface

Fire

Hot Liquid or Steam

THE INTERNATIONAL SYMBOLS USED

ON THE ENGINE OR

IN THIS MANUAL INCLUDE:

On Off

Fuel Shutoff

Read Operating

& Maintenance

Instructions

Stop

Fuel

Choke

Safety Alert

Oil

* Briggs & Stratton does not necessarily know what equipment this engine will power. For that reason, you should carefully read

and understand the operating instructions for the equipment on which your engine is placed.

Summary of Contents for 430447

Page 20: ......