6

For more information, visit www.desatech.com

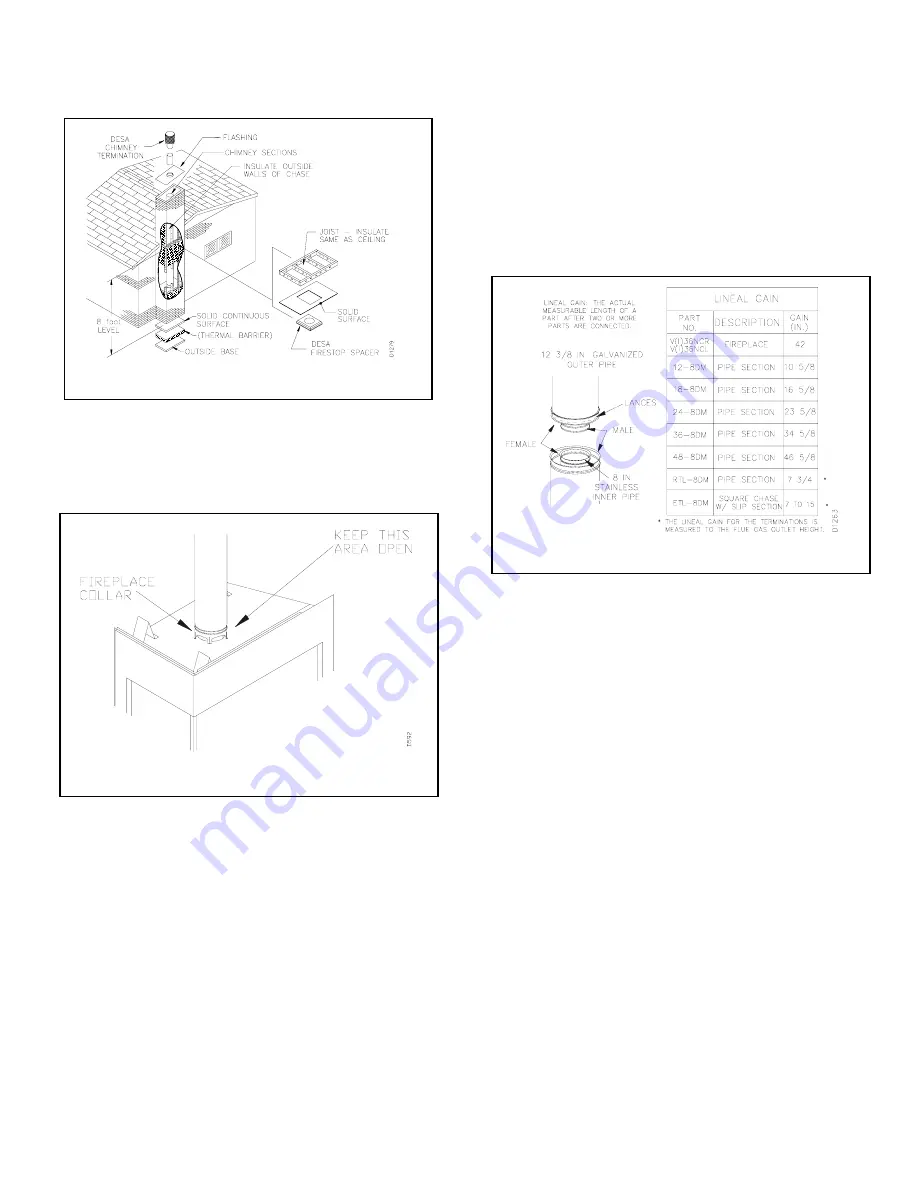

5. Do not insulate on top of the firebox. The opening in the

collar around the chimney at the top of the fireplace must not

be obstructed (see figure 10).

6. Before finishing the fireplace enclosure, inspect all joints of

the outer firebox. Seal any gaps of the outer firebox with a

non-combustible material. Caulk any gaps between the

nailing flange and framing.

CHIMNEY SYSTEM:

CHIMNEY HEIGHT

Minimum chimney height measured from bottom of fireplace

to flue gas outlet-end of the termination is:

Straight

run

14

feet

Run with one elbow set

15 feet

Run with two elbow sets

15 feet

An elbow set is consist of one starter elbow and one return

elbow. Uncommon circumstances such as neighboring hills,

tall trees, or strong wind areas can cause downdrafts in the

chimney system. In such cases, going beyond the minimum

recommended height would be preferable to provide a better

draw.

Maximum height approved for any chimney run with this

fireplace system is 60 feet as measured from the bottom of the

fireplace to the flue outlet-end of the termination.

ASSEMBLING AND INSTALLING THE DOUBLE WALL

CHIMNEY SYSTEM

The DESA chimney system consists of 12, 18, 24, 36 and 48-

inch, snap-lock double-wall pipe segments, planned for

maximum adaptability to individual site requirements. Actual

lengths gained (lineal gain) after fitting overlaps must be taken

into consideration (see figure 11).

Each double wall chimney section consists of a galvanized

outer pipe, a stainless steel inner flue pipe and a wire spacer.

The pipe sections must be assembled independently as the

chimney is installed. When attaching the chimney directly to

the fireplace, the inner flue pipe section must be installed first

with the female side up (see figure 11). The outer pipe section

can then be installed over the flue pipe section with the male

end up.

Press down on each pipe section until the lances securely

engage the hem on the fireplace starter. The wire will assure

the proper spacing between the inner and outer pipe sections

(see figure 11).

Continue to assemble chimney sections as outlined above,

making sure that both the inner and outer pipe sections are

locked together.

When installing double wall “snap-lock” chimney together, it

is important to insure that the joint between the chimney

sections is locked. Check by pulling chimney upward after

locking. The chimney will not come apart if properly locked.

It is not necessary to add screws to keep the chimney together.

However, if desired, use screws per directions provided on

page 7, figure 13.

Figure 9 COLD CLIMATE INSTALLATION

Figure 11

LINEAL GAIN

Figure 10 FIREPLACE COLLAR OPENING