15

100100

CHECKING

GAS

CONNECTIONS

PRESSURE TESTING GAS SUPPLY PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG

1. Disconnect heater and its individual manual shutoff valve from gas supply

piping system. Pressures in excess of 1/2 PSIG will damage heater regulator.

2. Cap off open end of gas pipe where manual shutoff valve was connected.

Continued

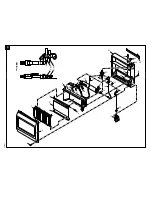

IMPORTANT:

Hold pressure regulator with wrench when connecting it to gas piping

and/or fittings.

Pressure

Regulator

Tee Joint

Reducer

Bushing to

1/8" NPT

1/8" NPT

Plug Tap

Test

Gauge

Connection *

Sediment

Trap

Tee Joint

Pipe

Nipple

Cap

Manual

Shutoff

Valve *

Heater

Cabinet

1/2" NPT

Pipe Nipple

Ground Joint

Union

Note:

Burner bracket

not shown for clarity

From

External Regulator

(11" W.C. to 14" W.C. Pressure)

3" Minimum

Figure 13 - Gas Connection

* An A.G.A. design certified manual shutoff valve with 1/8" NPT tap is an acceptable

alternative to test gauge connection. Purchase the optional A.G.A. design certified

manual shutoff valve from your dealer. See Accessories, page 27.

WARNING ICON

G 001

WARNING

Never use an open flame to check for a leak. Apply a mixture of

liquid soap and water to all joints. Bubbles forming show a leak.

Correct all leaks at once.

CONNECTING

TO GAS

SUPPLY

Continued

WARNING ICON

G 001

WARNING

Test all gas piping and connections for leaks after installing or

servicing. Correct all leaks at once.

WARNING ICON

G 001

CAUTION

Make sure external regulator has been installed between propane

supply and heater. See guidelines under

Connecting to Gas Sup-

ply, page 14.