PAGE

REVISION:

DATE:

VAN'S AIRCRAFT, INC.

PAGE

REVISION:

DATE:

2

RV-ALL

05-12

04/15/13

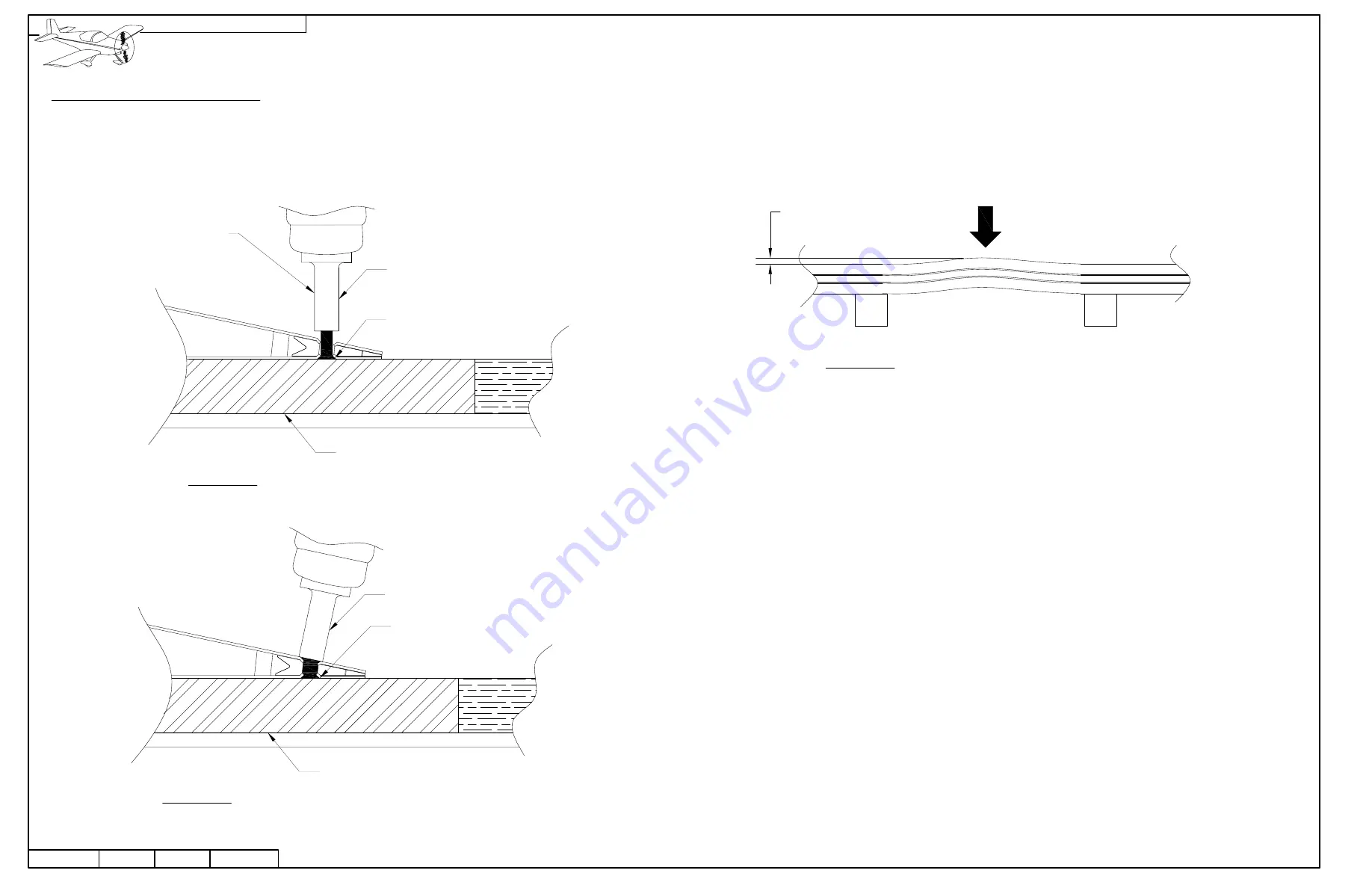

FIGURE 1: RIVETING THE TRAILING EDGE, INITIAL

FIGURE 2: RIVETING THE TRAILING EDGE, CONTINUED

RIVET GUN PARALLEL TO RIVET SHANK

STEEL PLATE INSET IN TABLE

MANUFACTURED HEAD

RIVET GUN PERPENDICULAR

TO SKIN

STEEL PLATE INSET IN TABLE

MANUFACTURED HEAD

FLAT FACED NARROW

DIA RIVET SET

(C-FRAME RIVET SET

WILL ALSO WORK.

SUPPORT BOTTOM

WITH FREE HAND)

5.8 RIVETED TRAILING EDGES (continued)

Set the rivet gun pressure low (it should take about three seconds to fully set a rivet). This will allow time to vary the angle of the rivet

gun while driving the rivet. Start with the rivet set parallel to the rivet shank and tilt it to set the rivet flush to the skin as the rivet sets.

Repeat the initial pattern until the rivets are completely set. See Figures 1 and 2.

Check constantly for any deformation of the trailing edge. If deformation over 1-2 in. [2.5-5 cm] in length is observed place blocks

near the curved area and lightly bend the trailing edge back down. Take your time and work as precisely as possible. An excessively

wavy or bowed trailing edge will affect the flying qualities of the airplane. Strive to build a trailing edge that does not vary more than

the dimension called out in Figure 3.

FIGURE 3: STRAIGHTENING THE TRAILING EDGE

NO GREATER THAN 0.1 (2.5 mm)