The servos used for the control surfaces of this model must have a minimum of 6kg-cm (85 oz-in)

of servo torque. The servos with metal gear are strongly recommended.

Before beginning the assembly of the model, remove each part from its bag for inspection. Closely

inspect the fuselage, wing panels, rudder, and stabilizer for damage. If you find any damaged or

missing parts, contact the place of purchase.

If you find any wrinkles in the covering, use a heat gun or covering iron to remove them. Use caution

while working around areas where the colors overlap to prevent separating the colors.

Radio Equipment

• 4-channel radio system (minimum)

• 1 standard servo for throttle

• 5 hi-torque servos

Recommended Engines

• D-30, R-26, Q-26

• Propeller (consult engine instructions)

• Servo Extensions

• Y-Harness

Adhesives

• 6-minute epoxy

• 30-minute epoxy

• Thick CA glue

• Threadlock

Additional Required Items

Tools

• Adjustable wrench (small)

• Drill (drill press preferred)

• Hook and loop straps

• Foam

• Hex wrench

• Hobby knife

• Phillips screwdriver (small)

• Pliers

• Scissors

• Square

• Measuring device (e.g. ruler, tape measure)

Servo Selection

Before Starting Assembly

18

3

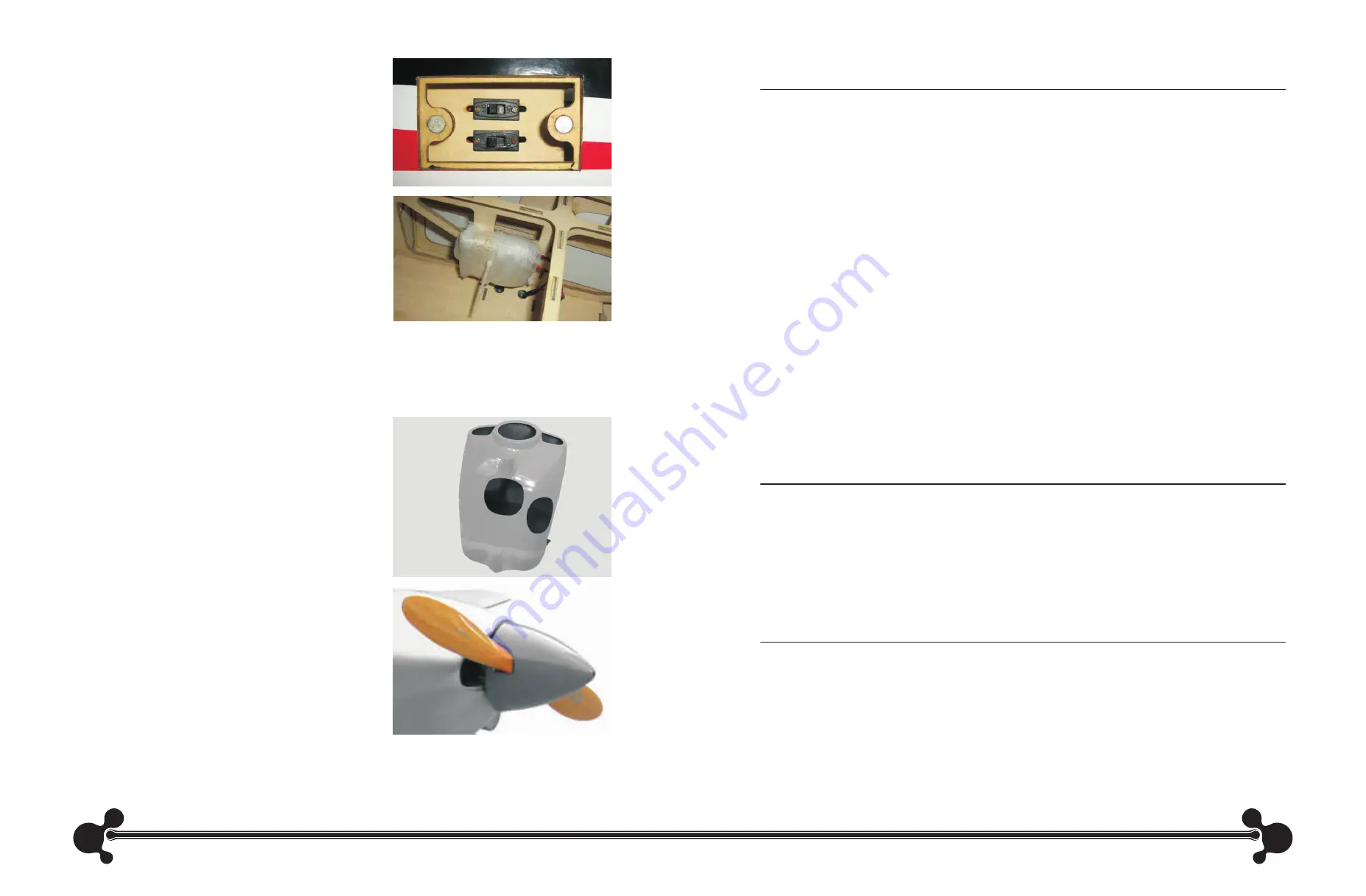

Step 9

Install the switch for the ignition in the switch hatch on the

side of the fuselage as shown.

Note: As the cowling mounting screw is inside the fuselage under the hatch, you need to open

the hatch before accessing the screw. To open the hatch, just remove the screws holding it on

both sides of the fuselage and lift the hatch from the fuselage.

Step 10

Secure the battery for the ignition inside the fuselage

using a hook and loop strap. Make sure to add a few

pieces of foam between the fuselage and battery to

prevent damage to the battery caused by vibration.

Connect the battery to the ignition switch.

Step 12

Route the vent line from the fuel tank out of the bottom of the cowling.

Step 11

Attach the fuel line from the fuel tank to the carburetor. Make sure the line is from the clunk and not

the vent line.

Step 13

Make any necessary cutouts to clear the engine

components in the cowling. Remove a section

from the bottom of the cowling near the exhaust

pipe for cooling outlet as shown. This opening is

necessary to allow cooling air to pass through

the cowling to prevent overheating of your engine.

Step 14

Slide and lock the cowling to the fuselage and

then secure the cowling with a screw. Mount the

propeller and spinner to complete the procedure.