6

Flooring:

If the floor on which the stove is to be placed is inflammable, the floor must be covered with non

-flammable material, such as steel or glass plate, floor tiles or artifical slate, covering an area of

at least 15 cm from the sides of the stove and at least 30 cm from the front of it. Regarding the

front, however, we recommend 50 cm. Also, the Floor construction must be capable of carrying

the combined weight of stove and chimney.

Installation distance:

If walls are non-inflammable, the stove can be placed closer to them. However, we recommend

a minimum distance of 5-10 cm, to allow for cleaning behind the stove. The cleanout gate must

be accessible. Optimal combustion can only be obtained if fresh air is constantly admitted. It is

important, therefore, to ensure that this is the case. The best way to provide a steady flow of

fresh air is by installing 1-2 air vent’s in the room where the stove is situated. (One in each side

of the room).

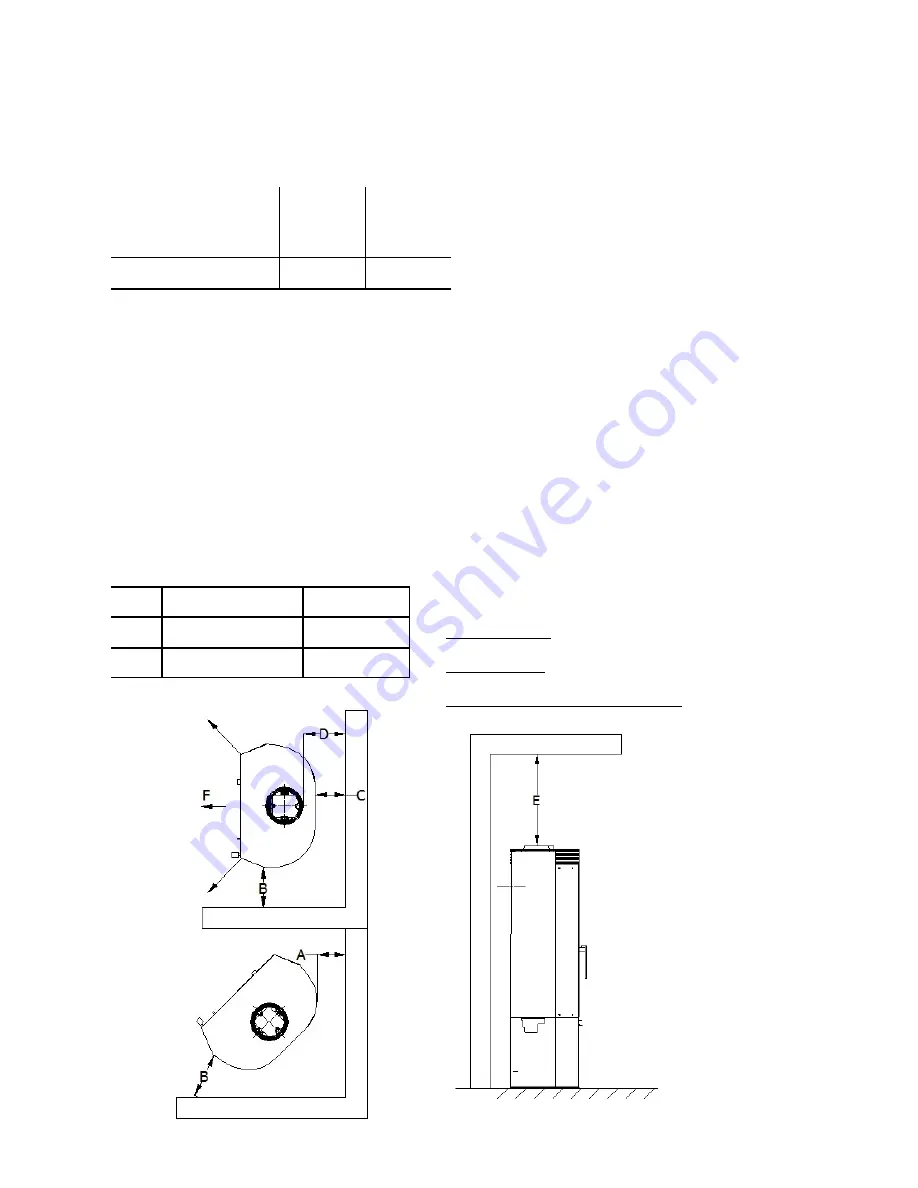

According to existing regulations, stoves must be placed with the following minimum distances

in mm to inflammable walls and materials.

The safety distance from a non-insulated chimney pipe to inflammable walls and materials must

be at least 450mm.

The stove must in accordance with applicable

rules comply with the following minimum distan-

ces from inflammable walls and materials:

Sides : 25 cm

Rear : 25 cm

Distance to furniture : 100 cm

Weight

Steel

With

Soapstone

Varde Vision

110 kg

120 kg

A

200 mm

C

250 mm

B

200 mm

D

300 mm

Varde Vision

F

1000 mm

E

600 mm