12 Maintenance and Troubleshooting

Varec, Inc.

133

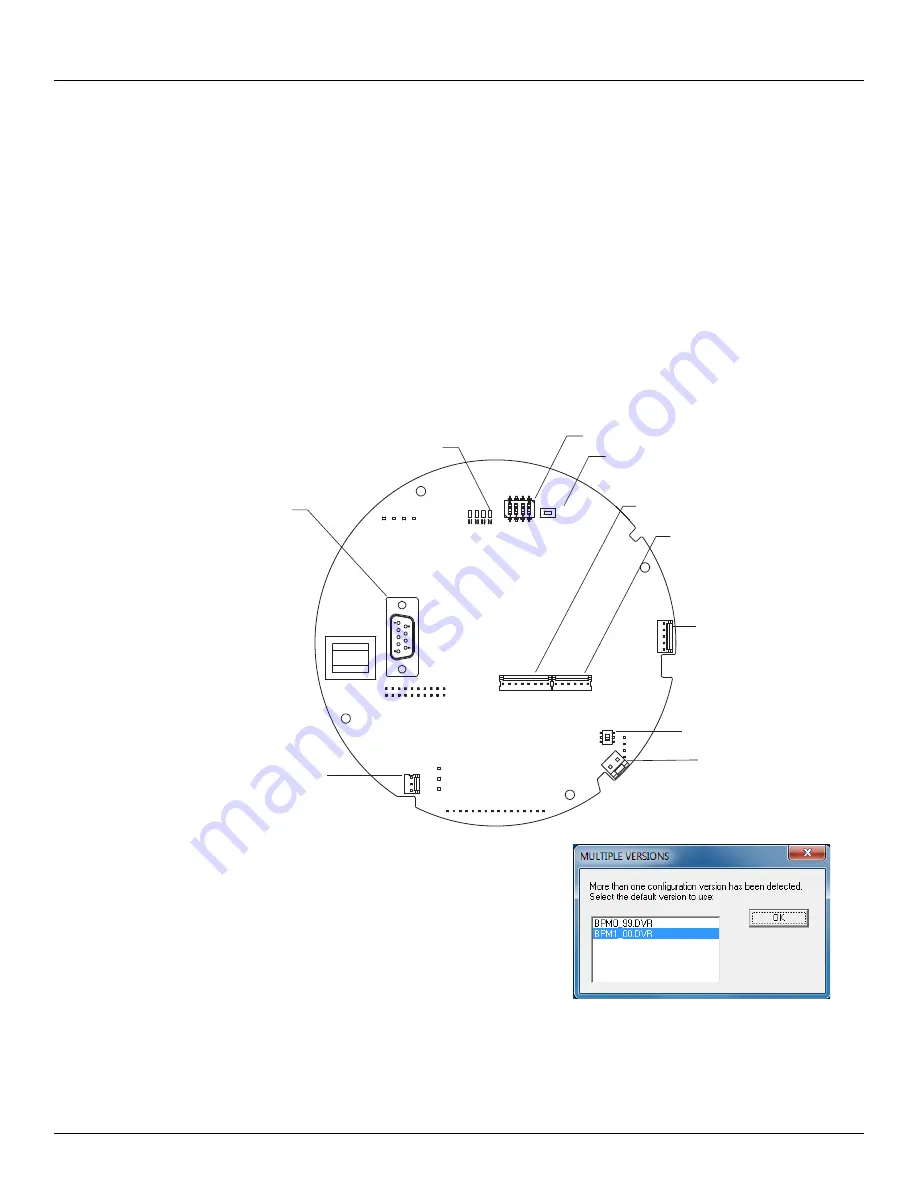

Using ViewRTU to Troubleshoot the 2920 FTT

For diagnostics and troubleshooting of the 2920 FTT, a laptop computer running the ViewRTU

software can be connected to the RS-232 port. The user can then use ViewRTU to run

diagnostics or perform other troubleshooting procedures on the transmitter.

Warning!

Obtain a hot permit before removing the transmitter cover with power

applied.

Note

For more detailed information regarding the ViewRTU program, refer to any Varec

RTU Installation and Operation manual.

1. Remove the 2920 FTT cover.

2. Connect the communications port of a laptop computer running ViewRTU software to the

RS-232 connector (J6) on the communications circuit board using a crossover (Null

MODEM) cable. The following figure shows the connector.

3. Start the ViewRTU application.

You are prompted to select a firmware

version file. Select the file that

matches the communications proto-

col used by the 2920 FTT, and then

click OK.

4. The main screen appears, as shown in

the following figure.

RESET

LED

SW1

J6

J8

SW6

J9

J7

J12

J11

SW2

J6

RS-232

J12

SW6

J11

J7

J9

J8

Reset SW2

SW1

LED D4

Summary of Contents for 2920

Page 2: ......

Page 16: ...2920 Float Tape Transmitter 1 Introduction 6 Installation and Operations Manual...

Page 114: ...2920 Float Tape Transmitter 6 Bi Phase Mark 104 Installation and Operations Manual...

Page 120: ...2920 Float Tape Transmitter 7 MODBUS 110 Installation and Operations Manual...

Page 126: ...2920 Float Tape Transmitter 9 L J TankWay 116 Installation and Operations Manual...

Page 158: ...2920 Float Tape Transmitter 14 Ordering Information 148 Installation and Operations Manual...

Page 193: ......