Liquid Level Indicator

52

Installation and Operations Manual

Oil Recommendations for Oil Seal Accessory Units

GENERAL SERVICE

• Low pour point, food grade, water white, mineral oil.

SERVICE BELOW 25 °F (-4 °C)

• Automotive antifreeze compatible with aluminum and water (50/50 mix)

Caution

These oils may not be compatible with edible oils and potable liquids. Use prod

-

uct compatible substitutes for tanks holding products for human or animal consumption

or products that may react chemically with the oil.

Inspection

It is recommended that the first inspection after the unit has been placed in service be made

at the end of the first thirty-day period. Oil sealed units should be inspected immediately after

being placed in service and then daily for the first week. Subsequent inspections should be

made every 90 days (Table 8). The user may adjust the schedule for his own convenience and

safety, depending upon the product. Varec maintenance service contracts are available for 90-

day, 6-month, 1-year and 5-year periods at substantial savings.

Troubleshooting Common Problems

Friction is a common problem that affects indicator accuracy. Some liquids produce corrosion

in the mechanism. Periodic inspection and maintenance provided by a Varec service contract

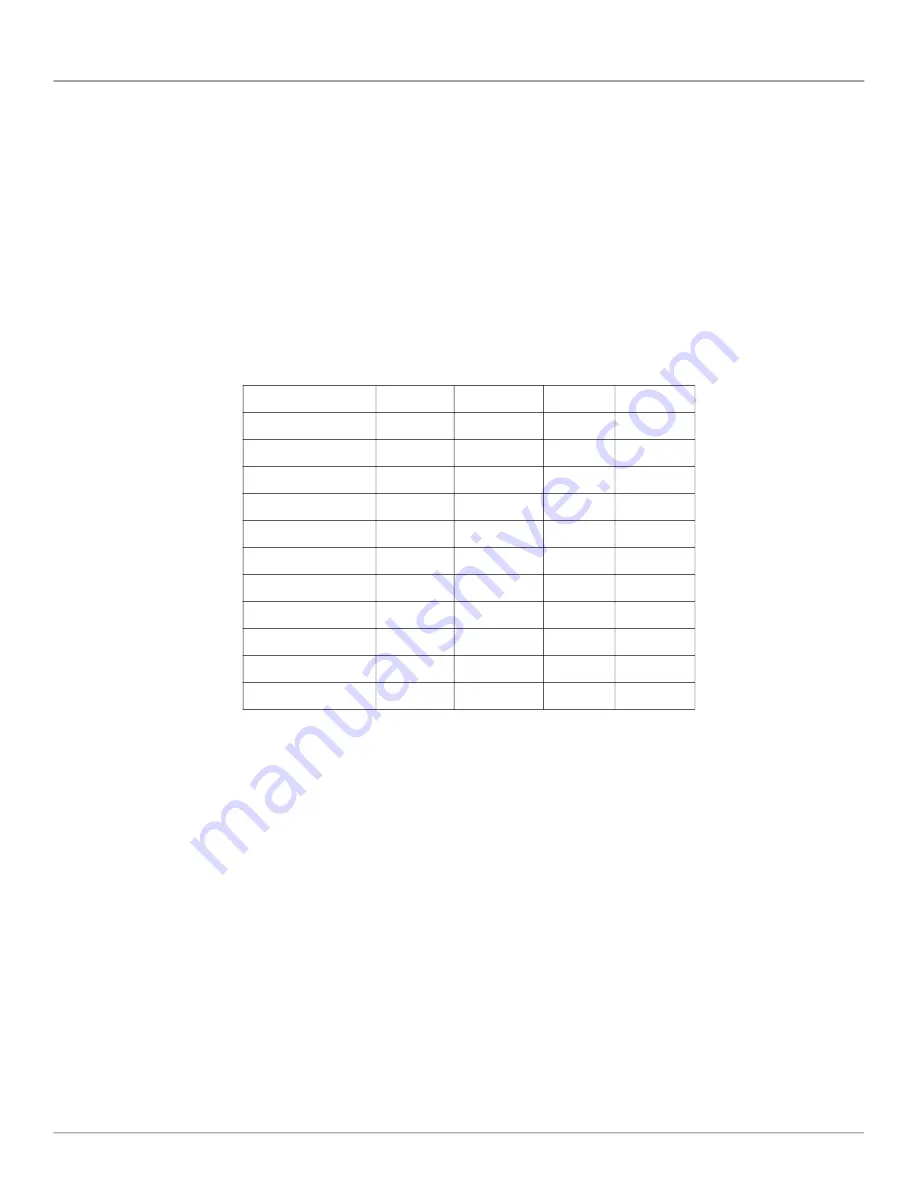

Table 8: Suggested Periodic Maintenance Schedule

Routine

90 Days

6 Months

1 Year

5 Years

Operation check

X

X

X

Guide cables

X

X

Float

X

X

Lubricate

X

Leak check

X

X

X

Change oil

X

Calibration

X

X

Corrosion check

X

Sediment check

X

X

X

Deformation check X

X

X

Refurbish

X

Summary of Contents for 6700

Page 2: ......

Page 25: ...Installation Varec Inc 17 Figure 8 Half Travel Cone Roof Tank Installation 16 50 419...

Page 39: ...Installation Varec Inc 31 Figure 15 Bolted Tank Installation 16 50 419...

Page 51: ...Installation Varec Inc 43 Figure 20 Severe Service Cone Roof Tank Installation 12 50 318...

Page 70: ...Liquid Level Indicator 62 Installation and Operations Manual...

Page 73: ......