BDR-595D Adela

10

7. Slide the apron with the holder (21) into a holder in the frame above the right mudguard

and secure it by tightening the plastic rosette

with the bolt (22).

5.2 Putting the machine into operation.

The machine may be delivered without engine fillings (in dependence on different

national regulations)!

First thoroughly read the instruction for engine use! You can prevent a possible

damage to the engine.

1.

Check oil volume in the engine and/or fill the engine with the prescribed oil grade and

volume. Fill the tank with the prescribed amount and type of petrol.

2.

Move the accelerator lever into the front position (

„CHOKE“

). Start the engine by

pulling on the manual starter (instructions for starting see guidelines for engine use).

3.

Let the new or cold engine running on choke for about 30 seconds (accelerator lever in

the

„CHOKE“

position), then move the accelerator lever into the position

„MAX“

. In

this position let the engine running for about 30 seconds.

Do not leave the machine alone when doing this.

5.3 Starting the cutting disk.

When starting the engine, the two levers on the handlebars must be in the off

position.

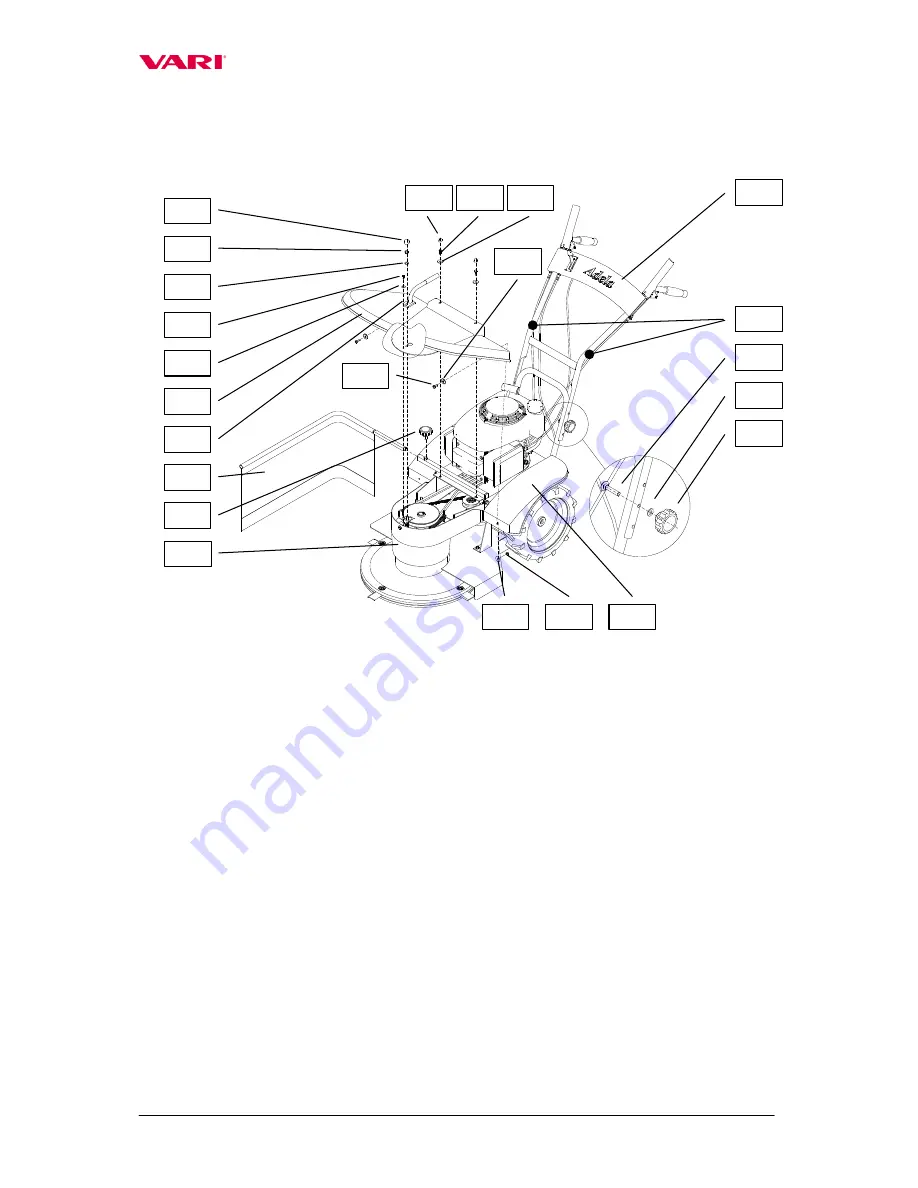

Figure 2: Machine assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

16

15

20

19

17

21

22

18

20

14

Summary of Contents for BDR-595 D Adela

Page 1: ...Brush cutter BDR 595 D Adela Instructions for use...

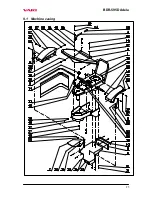

Page 7: ...BDR 595D Adela 7 LwA 2 1 8 3 4 5 6 7 11 12 9 10...

Page 25: ...BDR 595D Adela 25 9 1 Machine casing...

Page 27: ...BDR 595D Adela 27 9 2 Handlebars...

Page 29: ...BDR 595D Adela 29 9 3 Cutting disk drive...

Page 31: ...BDR 595D Adela 31 9 4 Wheel drive...

Page 33: ...BDR 595D Adela 33 9 5 Gearbox...