BDR-595 E EuroAdela

17

7 Maintenance, care and storage

To ensure a long-term satisfaction with our product, it must be given proper care and

maintenance. Regular maintenance of the machine will prevent its early wear ensuring at the

same time a correct functioning of all its parts.

Follow all instructions for intervals of machine maintenance and adjustment. It is adviced

that you keep records on the number of machine working hours and on the conditions in

which the machine was working (for service purposes). Similarly as the current maintenance,

the post-season maintenance should be entrusted to one of our authorized service workshops

if you are not certain of your own technical skill.

,

Regarding the machine weight, its maintenance and adjustment are to be made by a

team of two persons.

7.1 Machine lubrication

7.1.1 Gear oil replacement and refilling

,

When replacing oils, follow the basic hygienic principles, regulations and laws

on environment protection.

The gearing works in an oil bath. Oil condition should be checked once a month (oil

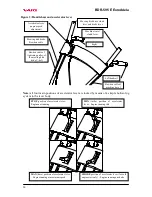

plugs see Fig. 4).

Minimum grade of gear oil according to API should be GL-4, GL-5; according to SAE:

90 or 80W-90.

Oil replacement in a new machine is to be made after the first 5 hours of operation and

then after 100 working hours or after the season. This will ensure that the gears will not

suffer excessive wear. The exchange interval can be extended up to 130 hours (the running-

in time of 5 hours must be adhered to) in higher oil grades (API GL-5, SAE 80W-90).

Czech oils fully meeting the requirements are MOGUL TRANS 90 or MOGUL TRANS

80W-90.

Oil replacement should be made when the gearbox is warm, oil can be drained easily.

1. Clean around the oil plugs. Underlay the machine and secure it so that a space is created

under the machine for a vessel to collect oil.

2. Loosen the pour-in plug on the rear wall of the box and the drain plug in the bottom of

the gearbox (spanner No. 19).

3. After the oil has been drained, screw back the drain plug in the bottom of the box. Fill the

gearbox with the new oil (it is adviced to use a funnel with flexible tubing). Oil level

should reach to the lower edge of the hole. Then screw the pour-in plug back. If the seals

under the plugs are damaged, replace them with new ones.

Summary of Contents for BDR-595 E EuroAdela

Page 1: ...Drum mower BDR 595 E EuroAdela Instructions for use...

Page 8: ...BDR 595 E EuroAdela 8 LwA 2 1 3 4 5 6 7 8 11 12 9 10...

Page 28: ...BDR 595 E EuroAdela 28 8 List of components...

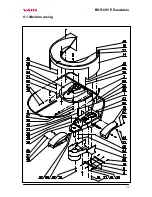

Page 29: ...BDR 595 E EuroAdela 29 8 1 Machine casing...

Page 31: ...BDR 595 E EuroAdela 31 8 2 Handlebars...

Page 33: ...BDR 595 E EuroAdela 33 8 3 Mowing disk drive...

Page 35: ...BDR 595 E EuroAdela 35...

Page 36: ...BDR 595 E EuroAdela 36 8 4 Wheel driving gear...