2.2 Operation safety

The machine is designed to protect its attendant from parts flying off the cut area. Do not remove any passive nor active safety elements. By doing so you expose yourself

to risk of injury.

2.2.1 Safety regulations

Machine attendants have to be aged

18

or over. The attendant

must be familiar

with the machine user manual and have knowledge of general work safety

principles.

Always switch off the engine and wait for the cutting disk to stop before starting any activity near the machine! Always switch the engine off before leaving the

machine!

Never leave the engine running at the maximum engine speed or running idle for a long time while the clutches of the cutting disk drive and wheel drive are

turned off. The machine drive parts could be damaged (V-belt, belt pulley, clutch pulley, etc.)!

Before each machine

use check all its parts (especially the operating mechanism and its covers) to see if they aren't loose or damaged. Revealed

defects parts

must be

rectified immediately

. For repairs, use the original spare parts only.

Remove any solid parts form the stand before cutting (such as stones, wires, loose construction leftovers, etc.), as these could be thrown away or damage the

machine. If these parts cannot be removed, avoid them.

The machine is equipped with a rotating implement. Maximum circumferential speed is

64 m.s

-1

. It is therefore important to keep other persons at a safe distance

while the machine is operating (there is a possibility of the cut stand or solid objects chipping off)!

Since the recommended noise and vibration levels are exceeded, follow the following instructions when operating the machine:

a)

Protect your ears with appropriate safety devices according to

EN 352-1

(shell-shaped ear protectors) or

EN 352-2

(plug ear protectors). Ask your

dealer for these safety devices.

b)

After every 20 minutes maximum of operating the machine interrupt the work for a 10 minute break. During these breaks, the machine attendant must

not be exposed to other noise or vibrations.

When operating the machine, use work aids approved by

EN 166

or

EN 1731

(tight clothes, firm shoes, work gloves and protective glasses.) Keep a safe distance

form the machine given by its handlebars.

Do not start the engine in closed spaces! Pay special attention when handling the machine. The engine exhaust muffler remains hot after the engine is switched

off. While adding the fuel, make sure it does not leak or spill over engine parts. If the fuel is spilled, dry the soiled parts or wait for the fuel to evaporate.

When the machine is being operated, all other persons (

especially children

) and animals must stay out of the machine's workspace. The machine attendant can

only continue working after taking these into a safe distance.

It is forbidden to remove any protective devices and covers from the machine.

Safe

climbing ability of the machine is 10º. Maximum engine tilt while working is 20º for long and 30º for short periods

35

.

Any machine repairs, adjustments, greasing and cleaning is to be carried out when the machine is turned off and disconnected the spark disconected.

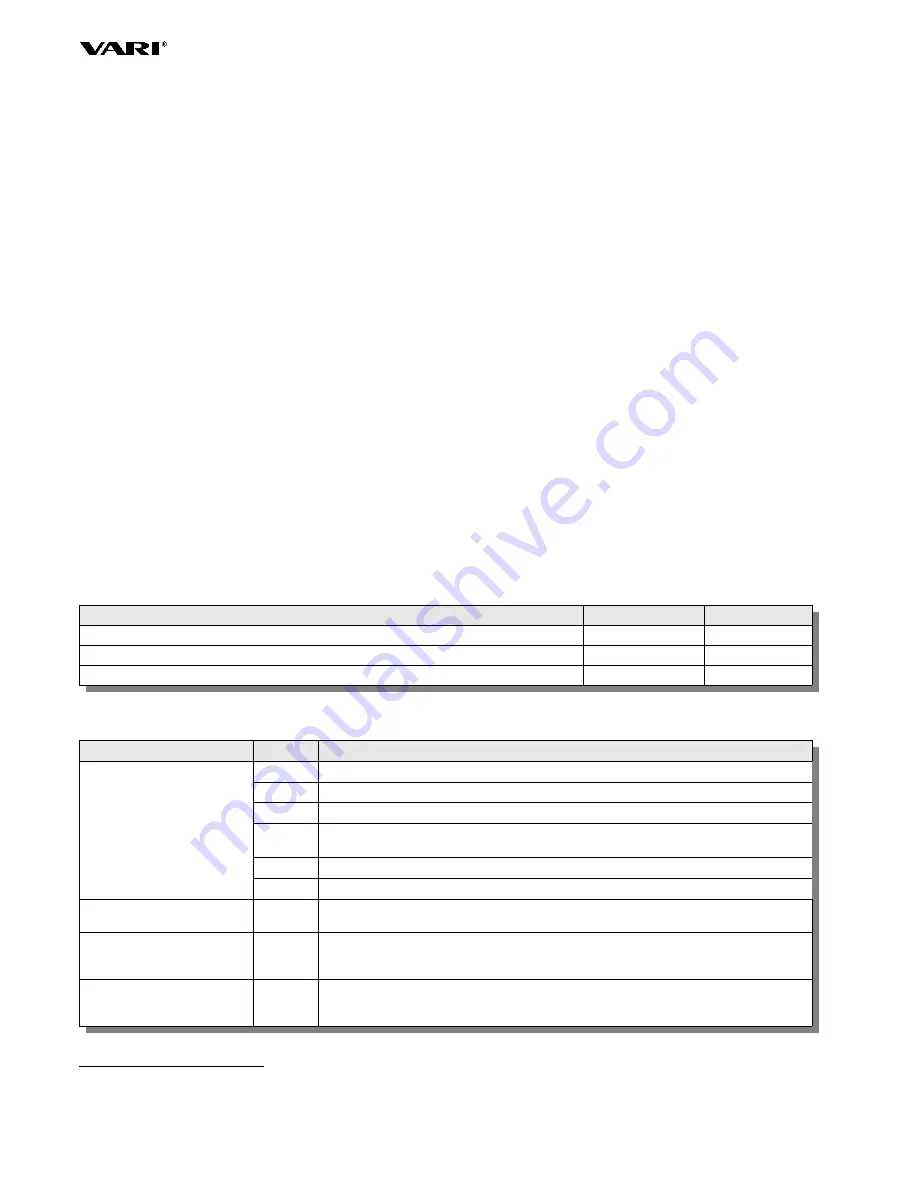

2.2.2 Noise and vibration values

BDR-620

BDR-620B

Declared

36

emission level of the acoustic pressure

A

at attendance point

L

pAd

= (82+1,5dB)

L

pAd

= (84+2dB)

Guaranteed

37

sound power level

A

L

WA,G

= 98dB

L

WA,G

= 98dB

Declared

38

aggregate acceleration value of the vibrations transferred onto the hand-arm of the machine attendant

a

hvd

= (7,3 +2,9 m.s

-2

)

a

hvd

= (6,3 +2,5 m.s

-2

)

2.2.3 Safety pictograms

The user is required to keep the machine pictograms readable, and have them exchanged in case they are damaged.

Locations:

Number:

Description:

Combined sticker, which is stuck

to the rear plastic cover. (

Pict.17

)

(1)

Study the user manual before operating the machine.

(2)

Spark plug cable must be disconnected during machine maintenance.

(3)

Do not reach with your arm nor step with your leg into the cutting blade work space – risk of cutting.

(4)

Risk of injury from chippings, cut-offs, flying objects, etc. Other persons and animals - keep safe distance

from the machine.

(5)

Adhere to the machine’s maximum safety climbing ability when working.

(6)

Guaranteed sound power level of the machine.

Separate sticker on the front

plastic cover. (

Pict.18

)

-

Tool turning direction arrow – to the right (clockwise)

Sticker (

Pict.20

) on the control

lever(1) on the right handle

(

Pict.2

).

-

Turning on the cutting disc drive. ‘

0

’ = the cutting disk is not rotating, ‘

1

’ = the cutting disc is rotating

Sticker (

Pict.19

) on the control

lever (2) on the left handle

(

Pict.2

).

-

Turning on the machine wheel drive. ‘

0

’ = the machine is standing still, ‘

1

’ = the machine is moving

Tab. 2: Safety pictograms

35

Short period = up to 1 minute.

36

According to

ČSN EN 836+A1/A2

, Appendix

H

and

ČSN EN ISO 11201

37

According to

2000/14/EC

instructions (equivalent of NV n.9/2002 Coll., Appendix n.3, part B, point 33) and

ČSN ISO 3744

38

According to

ČSN EN 836+A1/A2

, Appendix

G

and

ČSN EN ISO 20643

16

Summary of Contents for BDR-620

Page 2: ......

Page 13: ...BDR 620 BDR 620B 13...

Page 14: ...14...

Page 25: ...BDR 620 BDR 620B 25...

Page 26: ...26...

Page 35: ...BDR 620 BDR 620B 3 5 5 10 2x 5 5 5 20 6 3 5 6 7 35...

Page 38: ...38...

Page 39: ...40...

Page 50: ...BDR 620 BDR 620B 51...

Page 51: ...52...

Page 56: ......

Page 57: ......

Page 58: ......