In case the brake does not stop the cutting disc in the given time span, it is necessary to adjust the brake cable (2)

Pict.10

a

11

.

.

Adjusting screw, which

tightens the brake cable (2) to the cutter frame

Pict.10

, needs to be screwed in against the direction of the arrow (towards the frame), so that the axial clearance of

the brake cable in the adjusting screw is 1 mm. Check the automatic brake function. If complete tightening the screw (2) does not offer adequate brake effect,

tighten the adjusting screw of the brake cable on the handlebars so that the axial clearance of the brake cable in the adjusting screw is 1 mm. Check the automatic

brake function

57

.

If, after the adjustment

58

, the brake does not work properly, contact an authorised service center.

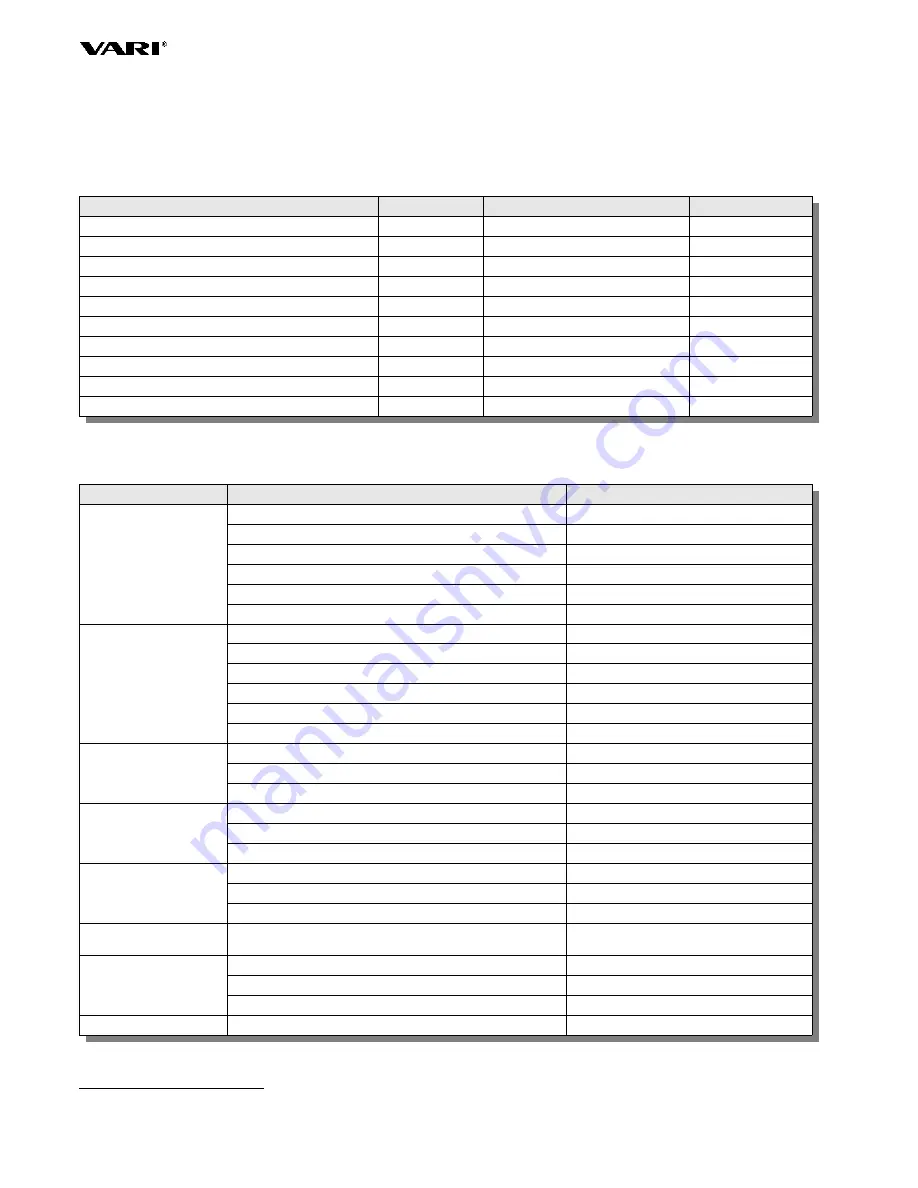

2.5.5 Service intervals

Activity

Before cutting

In season

Before storage

Engine oil level check

yes

following the engine user manual

yes

Cleaning the engine air filter

check

every 10 hours

yes

Washing

-

2x

yes

Removal of dirt and cut stand remains

-

after each cutting

yes

Blades sharpening

-

according to need

yes

Check the blades and their placing

yes

immediate exchange if damaged

yes

Cutting disk tightening check

yes

-

yes

Bolted connections tightening check

yes

every 5 hours

yes

Lubrications

condition check

Tab. 5

Tab. 5

V-belts check

-

every 20 hours

yes

Tab. 6: Service intervals

2.5.6 Problems and solutions

Problem

Cause

Solution

Cutting disc is not spinning

the engine is not running

Start the engine

wheel drive clutch lever is not pressed

Press the lever

insufficient belt tightening

Adjust the tightening pulley

broken belt

Exchange the belt with a new one

fallen belt

Mount the belt

other defect

Visit the service centre

The cutter does not move

the engine is not running

Start the engine

wheel drive clutch lever is not pressed

Press the lever

insufficient belt tightening

Adjust both tightening pulleys

broken belt

Exchange the belt with a new one

fallen belt

Mount the belt

other defect

Visit the service centre

Engine does not start

there is no petrol in the tank

Refuel

petrol feed is closed

Open petrol feed

other defect

Visit the service centre

Brake does not work

there is no axial clearance in the brake cable, the cable is tight

Adjust the brake

cam is hard to move

Lubricate

brake lining has deteriorated – impossible to adjust the brake

Visit the service centre

Impossible to stop the cutter

wheel drive pulley is broken

Exchange it with a new one

tight cable wire; bended cable

Lubricate or exchange cable

tightening pulley does not come back

Lubricate

Impossible to stop the cutting

disc

tightening pulley does not come back

Lubricate

Control levers do not come back tight cable wire; bended cable

Lubricate or exchange cable

return spring is broken

Exchange it with a new one

other defect

Visit the service centre

Other defect

Visit the service centre

Tab. 7: Problems and solutions

57

You may follow opposit instructions. First tighten the screw of the brake cable (towards handebar rail) on the handlebars so that the axial clearance in the adjusting screw is 1 mm. .

58

The condition of the axial clearance of the brake cable in the adjusting screw is met.

22

Summary of Contents for BDR-620

Page 2: ......

Page 13: ...BDR 620 BDR 620B 13...

Page 14: ...14...

Page 25: ...BDR 620 BDR 620B 25...

Page 26: ...26...

Page 35: ...BDR 620 BDR 620B 3 5 5 10 2x 5 5 5 20 6 3 5 6 7 35...

Page 38: ...38...

Page 39: ...40...

Page 50: ...BDR 620 BDR 620B 51...

Page 51: ...52...

Page 56: ......

Page 57: ......

Page 58: ......