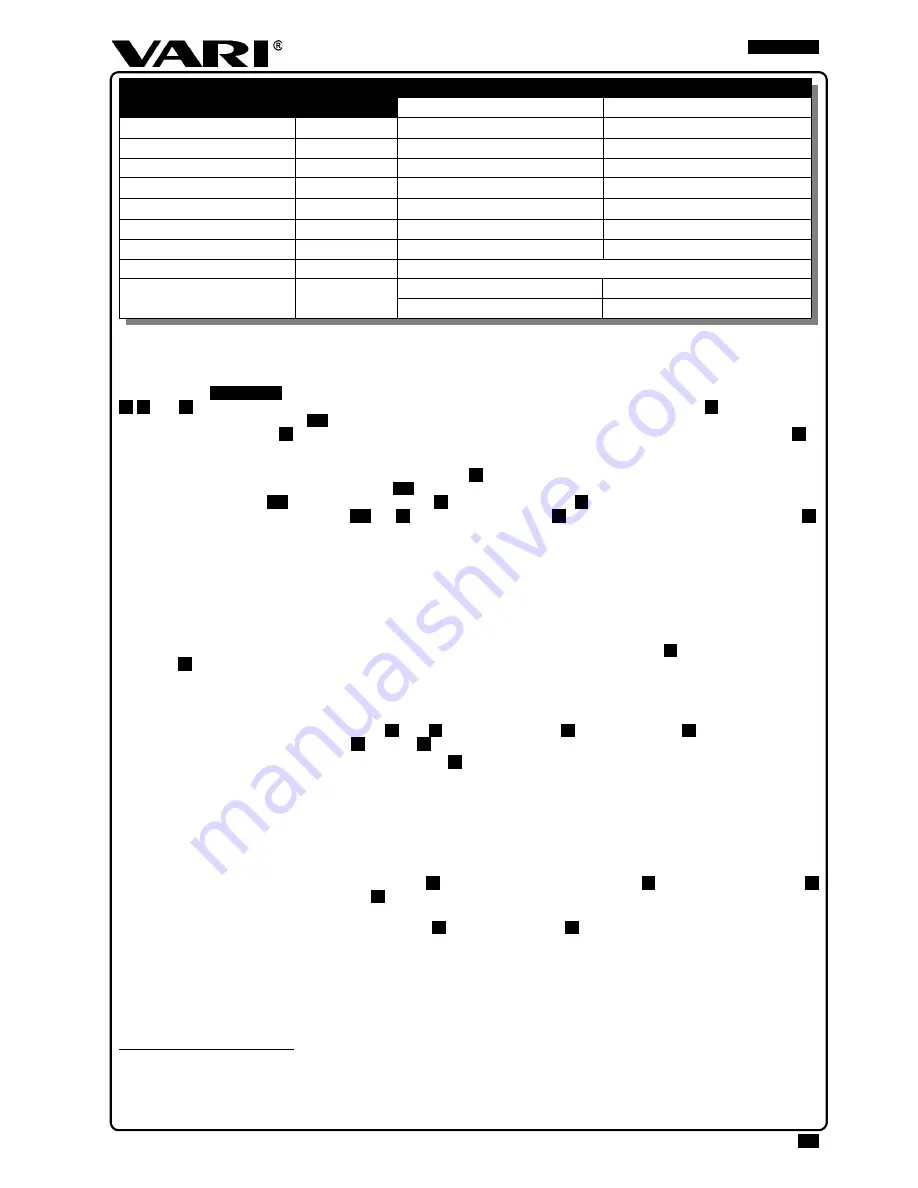

Lucina MaX

Engine

Unit

Value

BDR-620

BDR-620B

Type

-

HONDA

42

GCV-190

Briggs & Stratton

43

850 Series™

Maximum (set) engine rpm

min-1

3200 ± 100

3200 ± 100

Maximum engine tilt (long period)

20°

15°

Maximum engine tilt (short period

44

)

30°

30°

Fuel tank volume

l (litre)

0,91

45

1,1

Fuel

(unleaded) petrol

ON 91-95

ON 91-95

Engine oil filling

l (litre)

0,55

0,6

Oil quality

SAE

SAE 10W-30 or (SAE 30/SJ or SH)

Ignition plug

-

NKG BPR6ES

CHAMPION QC12YC

BRISK LR15YC

BRISK DR17YC

Tab. 5: Engine technical information

2.3.2 Description of the machine and its parts

Drum mower

Lucina MaX

(

Pict.2

) is built on a steel frame, to which all important parts of the machine are attached. All

controls

1

,

2

and

4

are placed on the handlebars. Handlebars are attached to the frame with a

bolted

connection

3

and their height is

adjustable into 6 positions.

Handles

12

secure a firm grip and machine handling during work. On the left side of the handlebars, there is

the

wheel drive clutch lever

2

which controls the movement of the machine in forward direction. On the right side, there is lever

1

of

the disc drive clutch for turning the cutting disk drive on (off). Both control levers return to their original position when the handlebars are

released in a critical situation and disconnect the engine power transfer. The cutting disk is equipped with an

automatic brake

46

which

stops the disk. Engine speed is controlled with an

accelerator lever

4

. The wheel drive is controlled by worm-gear unit with a belt clutch

which provides fluent power transfer onto the wheels

15

(the machine does not start with a jump). The gearbox and clutch are covered

by a plastic

gearbox cover

16

. There is the

cutting disk

7

with four

steel blades

8

in the front part. The attendant is protected

against flying parts of the cut stand by

cover

10

and

9

. A detachable

side screen

6

, which is attached with a

bolted connection

5

,

controls the line spacing.

2.4 User guide

2.4.1 Assembling the machine

As part of the pre-sale servicing, ask your dealer to unwrap the machine and give you a brief training on

how to use it!

Places for holding the cutter while removing it from the box (see

Pict.1

): by the cutting disc in the front

4

, by the machine frame tube

in the back

1

.

2.4.1.1 Assembling procedure

Use the following procedure for assembling the machine:

(It is advised to assemble the machine with a second person’s assistance)

1)

According

Pict.1

- take the disc cover

3

, bag

6

, side and rear screens

7

and a screen holder

2

out of the box. Pick the

machine up by its lift points in front

4

and back

1

and take it out of the box.

2)

According

Pict.2

- dismount the bolted connection

3

on both sides of the frame, take off the handlebars, turn them around

and put them on the frame as shown in the picture (choose one of the 3 holes in the handlebars to set their height). Re-tighten

the bolted connection firmly with your hand.

Control lever cables must not be crossed - this shortens their lifetime

!

3)

Take the draw bands out of the bag and tighten brake cables to the handlebars where the upper bending of the handlebars

tube ends. Two pieces of draw bands are sufficient for cable tightening.

4)

Dismount the self-locking nuts

47

M5 (2 pieces) and washers, mounted by the manufacturer, off the frame and set the disc

cover on the machine so that the holes fit in the screws in the frame, and the narrowed part of the cover is pushed in under the

engine plate. Put the washers and self-locking nuts M5 back on the screws and tighten them.

5)

According

Pict.1

-put the rear (shorter) screen

7

on the shorter arm of the screen holder

2

. Put the side (longer) screen

7

on the longer arm of the screen holder

2

. Put the clamp bands (2 pcs) through the holes in the screen holder and draw both

bands to fix both screens.

6)

According

Pict.2

- unscrew the fastening bolt

5

so that the side gate

2

can be easily pushed into the frame opening.

Tighten the fastening bolt with your hand and check that the side gate does not fall out spontaneously.

2.4.2 Putting into operation

The cutter may be delivered without the engine operating fluids

(according to various national rules)!

First read the engine user manual

48

carefully! This way, you may avoid possible damage.

42

More information about the engine including replacement part numbers can be found at

www.honda-engines-eu.com

43

More information about the engine including replacement part numbers can be found at

www.briggsandstratton.com

44

Short period – up to 1 minute.

45

Measured according to new

Society of Automotive Engineers (SAE) J1349 standard

46

The automatic break is an active protective feature that supports the machine’s safety.

47

Using wrench (preferably tubular wrench) n.10.

48

Multilingual manual and its Czech translation are part of the cutter.

19

R

ev

iz

e

0

5

/2

0

1

4

Summary of Contents for BDR-620B

Page 2: ......

Page 15: ...Lucina MaX 15 Revize 05 2014...

Page 27: ...Lucina MaX 27 Revize 05 2014...

Page 29: ...Lucina MaX 1 3 2 3 2 1 18 64 m s 1 EN 352 1 EN 352 2 20 10 EN 166 EN 1731 10 29 Revize 05 2014...

Page 34: ...Lucina MaX 3 4 3 3 4 3 1 4 5 10 5 3 4 3 2 5 4 3 4 3 2 1 1 2 3 3 5 34 Revize 05 2014...

Page 38: ...Lucina MaX 3 5 6 8 3 5 7 6 MAX 3 5 7 1 38 Revize 05 2014...

Page 41: ...Lucina MaX 41 Revize 05 2014...

Page 58: ...Lucina MaX 58 Revize 05 2014...

Page 59: ...Lucina MaX 59 Revize 05 2014...