F-530.1

22

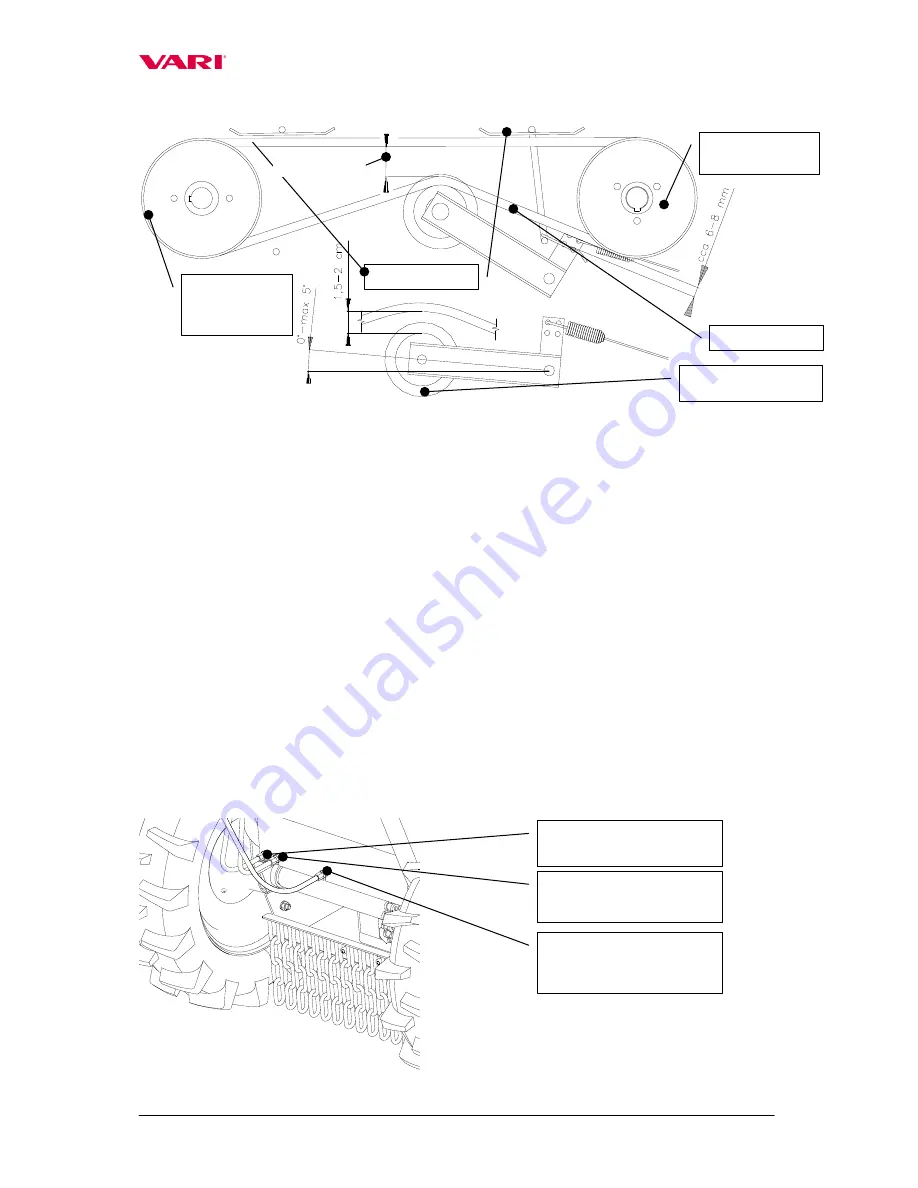

Figure 11: Adjustment of tightening pulley and maximum extension of V-belt

6.5 Setting-up litz wires of pulley, brake and machine travel gear

clutch

In order to guarantee low operating forces on levers which control drive switching, it is

adviceable to lubricate cables in Bowdens at least 2x during the season with some oil

available in atomiser (e.g. SILKAL, MD Spray, WD40). Correct functioning of the machine

also requires correct adjustment of drive controls.

The cable in the brake Bowden must always exhibit slight slackness (with the mowing

disk drive clutch lever and brake released) so that the brake performance is sufficient.

The cables in the pulley Bowden and in the Bowden of machine travel gear clutch must be

without slackness, slightly tense.

Safety nuts in all adjustment bolts should be tightened by using two spanners No. 10 or

No. 9. If there is no more step to be used in the adjustment bolt, it is possible to displace the

hook on the cable into another hole in the metal sheet lever on the handlebars (or on the

travel gear clutch lever on the gearbox and on the arm of the tightening pulley, see Figure 11

bottom) so that the pre-stress of cables can once again be regulated by the adjustment bolt.

Figure 12: Bowdens and adjustment bolts

Driven belt

pulley(mowing

knife)

Drive belt pulley

( engine)

Tightening pulley

V-belt

Brake Bowden and

adjustment bolt No. 1

Pulley Bowden and

adjustment bolt No. 2

Machine travel gear clutch

Bowden and adjustment bolt

No. 3

Guide lamin.

Min 7 mm

Summary of Contents for F-530.1

Page 1: ...Mulcher F 530 1 Instructions for use 2003...

Page 27: ...F 530 1 27 9 1 Knife casing and guide wheels...

Page 29: ...F 530 1 29 9 2 Mowing knife drive...

Page 31: ...F 530 1 31 9 3 Handlebars...

Page 33: ...F 530 1 33 9 4 Wheel drive gear...

Page 35: ...F 530 1 35 9 5 Gearbox...

Page 37: ...F 530 1 37 9 6 Swinging and mixing knives slide shoe...

Page 41: ...F 530 1 41 Text and illustrations c 2002 VARI a s Publication No VL 061 2002...