F-550

MIN

imal

permitted tyre pressure:

18 PSI

(

124.1 kPa

or

1.24 bar

or

1.22 atm

or

0.124 Mpa

)

If the tyres permanently leak air, check if the tyre casing is damaged – if so, repair.

If you are not sufficiently technically competent, assign this task to a professional service centre.

2.5.1.2 Wheel idle function

Torque is transferred from the wheel axle by a circlip pin. Both wheels, the left or the right, may be disengaged from the transfer of force

on flat terrain by removing the circlip pin from one of the wheels. Only one wheel then drives and it then makes it easier to turn around at

the end of the row.

Keep in mind that the machine with such a setup shall turn (pull) towards the side, where the pin was removed.

2.5.2 Lubrication of the machine

When working with lubricants, follow basic hygiene rules and regulations and laws for protecting the

environment.

If you are not sufficiently technically competent, assign this task to a professional service centre.

Adequate care must be taken when lubricating to ensure problem-free and easy movement of all mechanical parts. Usually, several drops

of oil will suffice (e.g. bicycle oil). The gearbox is factory filled with sufficient oil, which does not need to be changed during the life of the

machine.

Check the oil level in the gearbox. If leaking, fill up with recommended oil.

2.5.2.1 Changing the engine oil

Follow the directions specified in the engine operating manual. Reduce the exchange intervals to one half, if you use the machine in a

dusty environment. When draining the engine oil, tilt the machine to the side, where the filler and oil dipstick are or remove the entire

engine from the frame with the engine plate.

If you are not sufficiently technically competent, assign this task to a professional service centre.

2.5.3 Lubrication points

No cover needs to be removed from the machine when lubricating the cables on the handlebars. Other lubrication points are accessible

after remove the plastic covers. From the wide variety of oils, any engine oil, gearbox or transmission oil, or spray oil is appropriate. From

plastic lubricants (grease), any grease made for lubricating water pumps will fully suffice. The corresponding ball bearing must usually be

removed to apply it, however.

When using grease with added graphite, the lubrication intervals during the season may be extended up to

25 hours

.

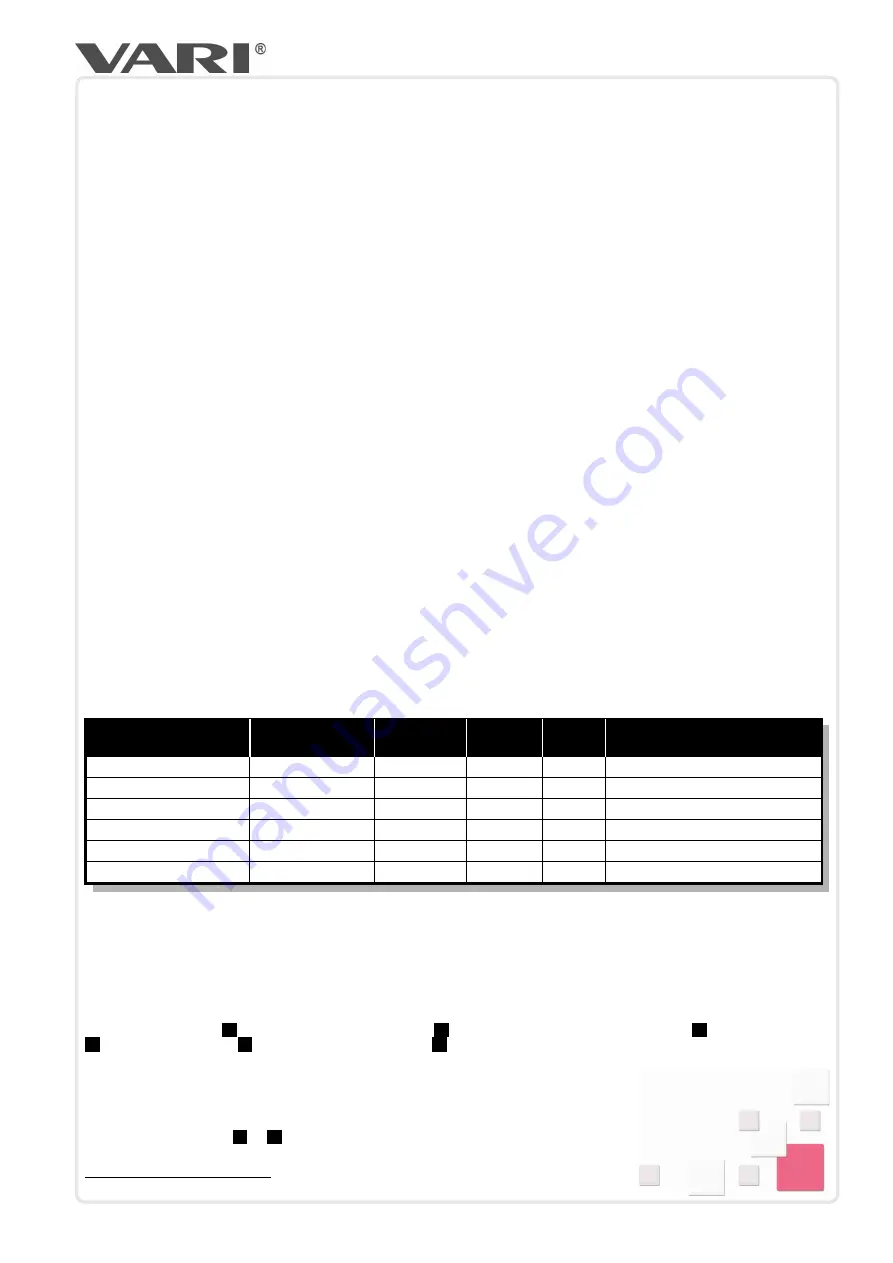

Lubrication point -

description

Seasonal interval

After-season

Lubricant

Picture

Comment

Control lever cables

At least 2x (5 drops)

yes

oil

Pic. 14

Entrance of all cables into the control lever

Wheel drive pulley

every 20 hrs. (2 drops)

yes

oil/grease

Pic. 11

Arm housing

Drive clutch pulley

every 20 hrs. (2 drops)

yes

oil/grease

Pic. 13

Interface with the frame

Brake cam

every 10 hrs. (1 drop)

yes

oil

Pic. 11

Rotation pin

Spur

every 30 hrs.

yes

grease

Pic. 8

Handlebars - fastener

-

yes

grease

-

Screw connection

Table 6: Lubrication intervals

2.5.4 Sharpening, replacing the work tool

If the work tool blades are worn or damaged, cause the machine to vibration, the blades need to be restored or replaced. Even though

the work tool is made from high quality hardened steel, blade wear occurs leading to less efficient cutting.

The machine must be standing on a solid base and secured such that it affords goods access to the blade and

spontaneous movement of the machine does not occur.

To remove the

blade

(

3

on

Pic. 6

) from

the blade holder

2

, first loosen and remove the

centre screw

5

. Then loosen

the nut

1

and loosen both

screws

4

and remove. Take out the

blade

3

.

The manufacturer disclaims any liability for damage to property or injury caused by the machine or to the

machine when replacing the work tool with a non-original part. A symbol is imprinted on the blade that

designates the manufacturer and it serves as an inspection symbol that the blade is an original replacement part!

If the screws (

4

or

5

) are damaged, replace them with new ones!

67

If the tyre pressure is below the minimal level, the tyre casing becomes damaged and the life expectancy of the tyre is thereby significantly reduced.

26

02

/2

01

3