Hurricane MaX

Immediately stop the machine travel and slightly back-up with the machine front slightly lifted (

pushing the

handlebar downwards

). The working space will partially clean itself from excessive material. Then move again

against the growth.

2) The working tool stopped, the engine choked.

Release both control levers on the handlebars and lift the front of the machine. Slide the machine slightly backward.

Clean the area under the top cover and spread the grass mass over the surface. Start the engine, turn on the working

tool drive, and start moving against the growth.

3) Liquidated growth gets trapped on the side of the working space cover (probably dense and overgrown growth).

Try to change the direction of your travel through the cut growth, or you may lift the front of the machine to liquidate

the growth top part. Then move again against the growth.

Try to install the optional accessory

Mulching device cover Ord. No. 4447

. This will extend the length of the

working space, and the cut growth will then be better aligned before entering the working space.

2.4.4 R

EPLACEMENT

OF

ACCESSORIES

- R

ECONFIGURATION

Replacement of the accessories with another adapter is only possible for brush cutters with the trade name

type designation starts with

F-580

.

The

Hurricane

brush cutters whose type designation also starts with

F-550

are only single-purpose machines, and

they are not designed for any adapter replacements

.

The

Hurricane MaX

brush cutter’s default adapter mounted to the

MaX

chassis is the

VM-580

brush cutter. It must be removed

before any accessory change.

Prepare, if possible,

2 spanners

No. 10 and

2 ring spanners

No. 13, and a box for fastening material to be used

later.

Always turn OFF the engine and wait for the work tool to completely stop before performing any work in the

close vicinity of the machine!

Disconnect the ignition spark plug cable. In the case of the F-580BiS machine with its electric starter, remove its

battery from the holder.

The machine must be placed on a hard horizontal surface and must be secured so that there is good access

to all the machine parts, so the machine does not move unexpectedly.

We recommend completing this activity by two persons.

2.4.4.1 W

ORKING

MECHANISM

REMOVAL

Exercise elevated caution when handling tools in the working space area. The working tool cutting edges are

quite sharp. You may injure yourself.

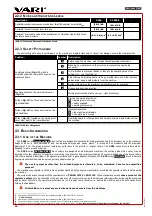

Please observe the following procedure per the individual steps

>

in

Fig. 10.

1)

Removing the rotary support body of the working tool:

Using spanner No. 10 unscrew per step

>1

both M6 nuts

A

and

remove the plastic cover

of belt drive

1

. Lift the front of the machine (by pushing down the handlebars) around the wheel axle

to its approximate position per

>2

and secure the machine against tipping over. Using spanner No. 13, loosen and unscrew per

step

>3

three M8 bolts

B

. Loosen and unscrew last fourth bolt M8

B

, while holding the body of blade

2

by hand, to prevent

the fall and potential damage of the working tool or any important part of the blade body. Upon unscrewing the last M8 bolt

B

,

remove the body away from the chassis frame and put it aside. Visually check per

>4

whether splined coupling

3

is fitted onto

blade body shaft

2

. If the coupling stayed on the shaft in the frame, remove it and transfer

to the blade body shaft.

2)

Removal of the front guide spur:

Using two No. 13 spanners, loosen and unscrew M8 bolt

C

per

>5

(

>3

). Unhook guide

spur arm

4

by rotating it in the arrow direction per

>5

from the chassis frame and put it aside.

3)

Removal of the working space sheet metal cover:

Following step

>6

(

>3

), unscrew M6 bolt

D

. Only loosen other M6

bolt

D1

, so the sheet metal cover stays attached to the chassis frame. Now, using a No. 10 spanner, following

>7

,

unscrew

both M6 bolts

E

and

E1

(

E1

is on the opposite side and is not shown).

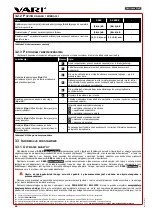

Take care of your own safety. During the next disassembly step, the machine may tilt back by its own weight. Be

careful, or ask another person to stabilize the machine by holding its guide handles.

4)

Unscrew last M6 bolt

D1

per step

>6

(

>3

) and move multi-purpose chassis

MaX

backwards.

5)

Belt drive covering

Attach plastic cover

1

per step

>8

in the reverse way, than during its installation in step

>1

. Place a

part of cover

1

under the engine plate and fit the cover openings onto the chassis frame bolts. Screw in both M6 nuts

A

and

tighten them gently. The cover is plastic and could break. Now, the chassis of your

MaX

brush cutter is prepared for attaching a

new adapter.

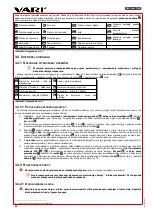

Never start the engine without its plastic belt drive cover on multi-purpose chassis

MaX

.

78

It must be purchased separately.

79

The sticker is affixed to the left side of the working space cover.

80

For quick installation, we recommend preparing, instead of 2 ring spanners, 1 ring spanner No. 13 and 1 ratchet (GOLA) with socket size 13.

81

Inside the cover, there you may keep the bolts from the next removal steps.

82

If possible, do not rotate it around its horizontal axis. Keep the original position in which it worked.

83

If you know that you will need to remove the cover again to install another adapter, do not replace it and do so later.

30

Re

vi

ze

1

0/

20

19

Summary of Contents for Hurricane MaX F-580

Page 2: ......

Page 4: ...Z ru n list CZ...

Page 21: ...Hurricane MaX 21 Revize 10 2019...

Page 55: ...Hurricane MaX 55 Revize 10 2019...

Page 61: ......

Page 62: ......

Page 63: ......