DS-520 Líza

DS-520H Líza

18

6.5 Tightening pulley wire and drive diagnostics.

In order to guarantee low operating forces on levers which control drive switching, it is

advisable to lubricate wires in Bowden cables at least 2x during the season with some oil

available in atomiser (e.g. SILKAL, MD Spray, WD40). Correct functioning of the machine

also requires correct setting of drive steering elements. Should the adjustment bolt be fully

screwed out and the V-belt needs to be tightened, wire spring can be hooked into the front

hole on the tightening pulley arm.

6.6 Driving problems diagnostics.

Excessive belt pull-out

(see Fig. 6)

Replace the belt with a new one

Slippage of mowing

disk drive

Tightening pulley does not

tighten the belt properly

Adjust the tightening pulley by means of

adjustment bolt (see Fig. 7)

Nuts are to be tightened by two spanners No. 10 or No. 9. Should there be no more step

on the adjustment bolt, spring on the wire can be hooked in the pulley arm hole for return

spring.

Problem

Reason

Remedial action

Mowing disk does not

turn

Tightening pulley does not

tighten the belt properly

Adjust the tightening pulley by means of

adjustment bolt (see Fig. 7)

Cable fallen out from tightening

pulley lever

Put the cable back

V-belt fallen behind tightening

pulley or out of belt pulley

Put the belt back

Torn V-belt

Replace the belt with a new one

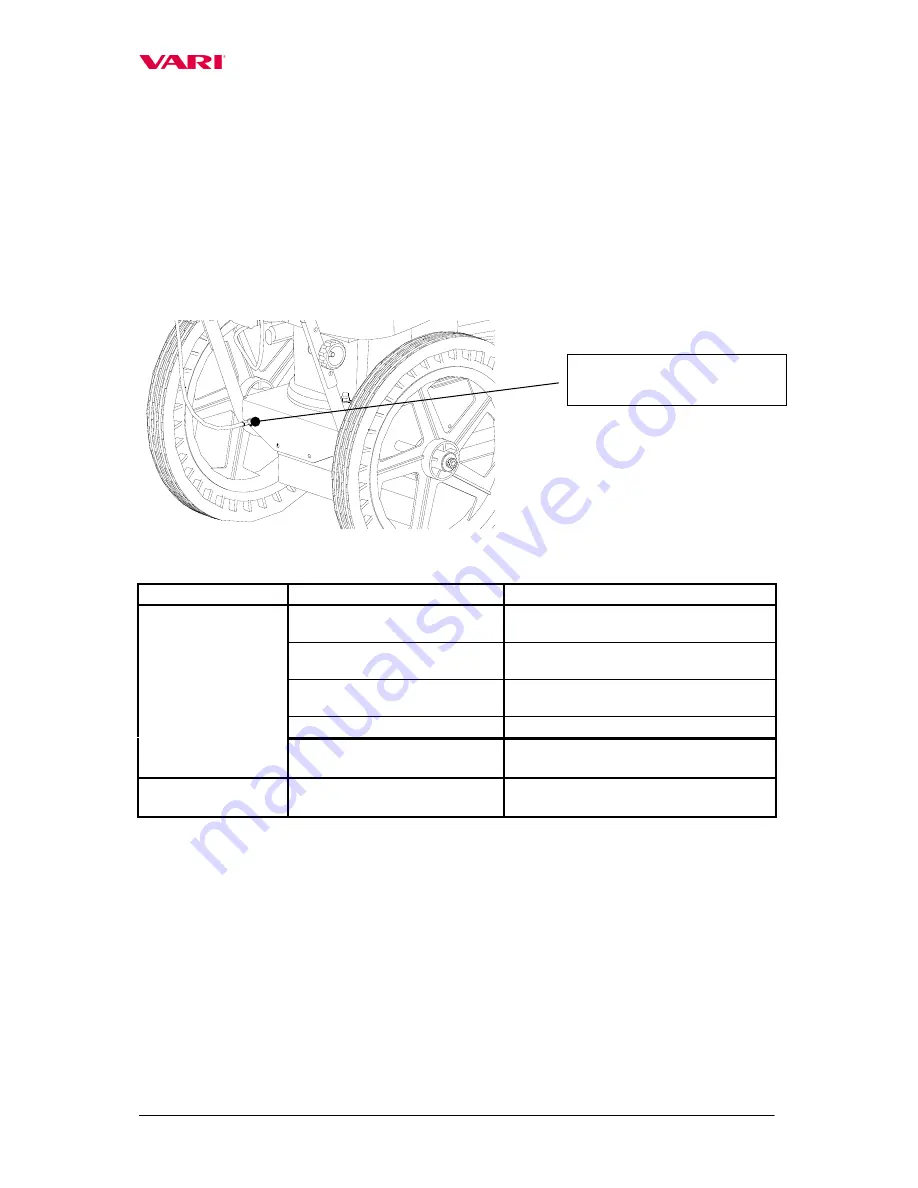

Pulley Bowden and adjustment

bolt

Figure 7: Bowden cable and adjustment bolt.

Summary of Contents for Liza DS-520

Page 22: ...DS 520 L za DS 520H L za 22 9 List of components...

Page 23: ...DS 520 L za DS 520H L za 23...

Page 25: ...DS 520 L za DS 520H L za 25...

Page 27: ...DS 520 L za DS 520H L za 27...

Page 31: ...DS 520 L za DS 520H L za 31 Text and illustration c 2002 VARI a s Publication No VL 064 2002...