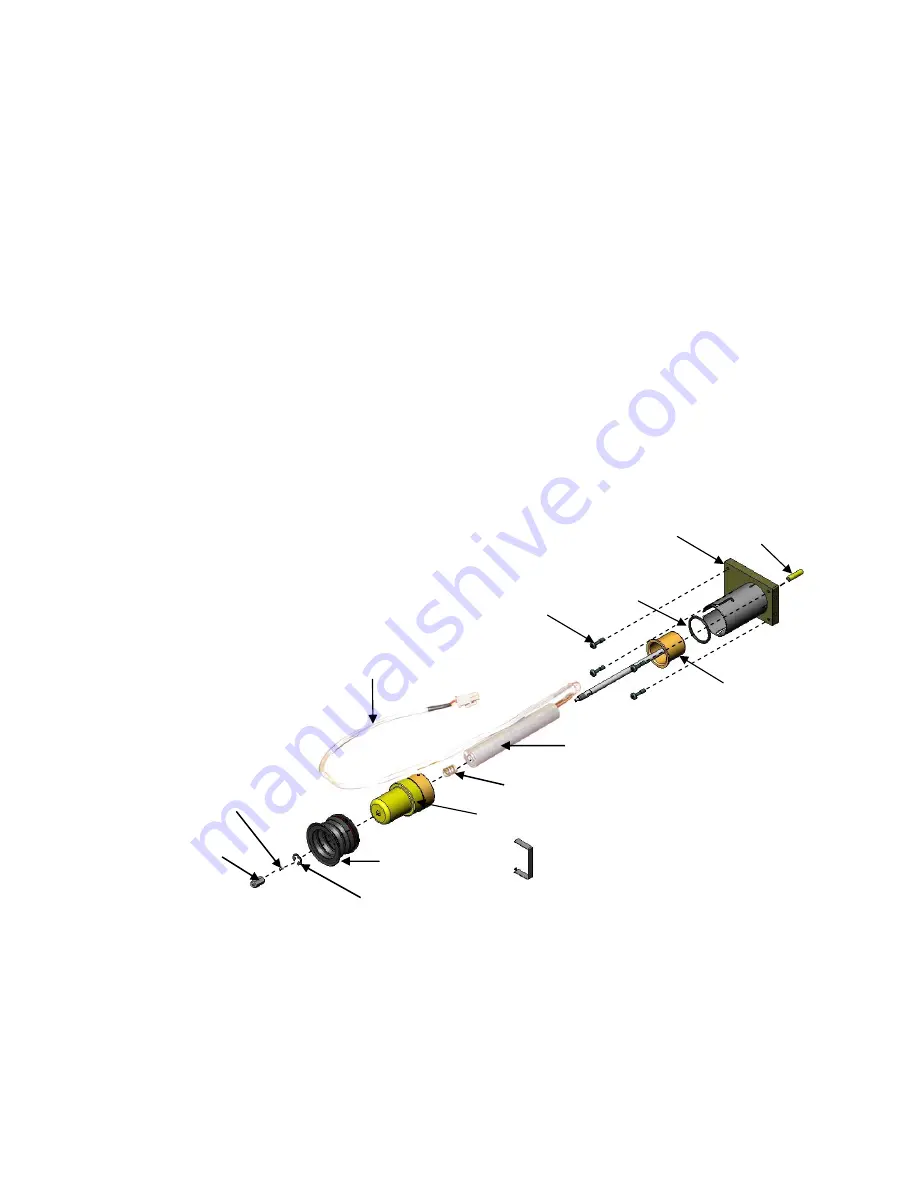

Transfer Line

A stainless steel tube transfer line directly couples the GC to the mass

spectrometer. The purpose of the transfer line is to keep the GC column warm as

the column enters the mass spectrometer to avoid condensation of the sample,

which could result in tailing. One end of the transfer line enters a hole in the right

side of the GC before passing into the GC oven. The other end enters the

vacuum manifold in one of two positions, depending on where the sample is to

be ionized. If the sample is to be ionized in the external source, the transfer line

is inserted into the source volume. If the sample is to be ionized in the trap, the

transfer line is inserted into a hole in the trap close to an electron generating

filament. Two different tips must be used to extend the GC column into the point

of ionization, depending on the mode used. A short Polyimide tip is used for

internal ionization and a long metal tip is used for external ionization. The body of

the transfer line consists of a stainless steel body fitted with a center tube, a heat

exchanger, and a boot. The heat exchanger is an aluminum cylinder that

contains a cartridge heater and a thermocouple as the temperature sensor. The

temperature sensor measures the temperature of the tube. The cartridge heater

heats the cylinder, which distributes heat evenly throughout the length of the

transfer line tube. The boot of the transfer line, which mates to the GC, prevents

hot air from leaking from the GC oven.

Bayonet Mount

Feature

Block Heater

Weldment

Compression Spring

Retaining

Clip

Quad

O-Ring

Brass Nut

Air Seal Boot

Nose-Collar

Captive Screw

(4 places)

Heater Cable

No-Hole Ferrule

Weldment

Retaining Clamp

(E Clip)

Exploded View of Transfer Line

A bayonet mount feature secures the transfer line. Before you remove the trap,

push gently on the bayonet mount as you twist it counterclockwise and pull the

mount out. Make sure the transfer line extends out from the trap.

9 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...