outlet labeled “LINE VOLTAGE - PUMP ONLY” on the rear of the MS. Power is

supplied through this outlet and is controlled by the power switch on the rear

panel.

The foreline pump used on the 4000 MS is a Varian DS-102 two-stage rotary

vane pump with a pumping speed of 90 L/min and a vacuum potential of

1.5 x 10

-3

Torr (2 x 10

-1

Pa).

If you use the 4000 MS to analyze hazardous materials, be sure to direct the

foreline pump exhaust to an exhaust system that complies with applicable

safety regulations.

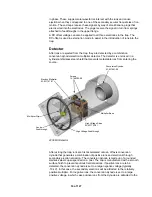

Turbomolecular Vacuum Pump

The Varian TV-301T Turbomolecular Vacuum Pump provides the high vacuum

for the 4000 MS. Under normal operating conditions, this pump supplies a

vacuum of approximately 10

-5

Torr (1.33x10

-3

Pa) in the manifold region outside

the ion trap assembly. The pump is rated at 230 liters/second; it is air cooled and

thermostatically protected. If the temperature of the pump housing near the

bearing exceeds 60 °C, the pump will automatically shut down.

A turbomolecular-pump controller regulates and supplies power to the pump. The

controller sits below the pump in the analyzer compartment of the spectrometer.

Turning off the main power switch on the rear panel of the mass spectrometer

shuts off power to the turbomolecular-pump controller and thus to the pump.

The electronics service switch does not turn off the vacuum pumps.

The turbomolecular-pump controller monitors the pump’s rotational speed. The

controller sends a signal proportional to the pump speed to the controller board

via the power board. You can monitor the turbomolecular pump speed from the

Diagnostics or the Startup/Shutdown tab dialogs in System Control.

If the pump speed falls below 94% of its maximum operating speed, the

VACUUM OK signal read by the Controller board turns off. The filament, electron

multiplier, RF generator, CI reagent gas valve, and calibration gas valve turn off

automatically. This condition probably indicates a major air leak in the system or

that the pump is too warm.

Ion Gauge

An ion gauge is present on the bottom of the vacuum manifold. Its design is

based on the Bayard-Alpert gauge tube. The specifications for the gauge are

similar to those of commercially available gauges. Fixed pressure readings with

nominally identical gauges may exhibit variations of

±

15%. An accuracy of

±

25%

in mid-range for any one gauge is considered typical.

The ion gauge generally exhibits good repeatability. However, the ion gauge

response depends on gas composition. A given pressure of air and water will

give a different reading than that of helium. The ion gauge is meant to be a rough

indicator of vacuum conditions. It is not a precise quantitative tool.

18 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...