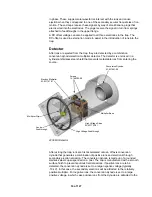

A power input sub-system distributes line voltage to various components as

needed.

RF Generator

Assembly

Controller Board

Power Board

Ion Trap

Source

Manifold Boards

(2)

(Source Voltage

Supplies/Emission

Regulator, End

Cap Electronics)

RF Coil

&

Detector

Ion Detection

Board

(Conversion

Dynode, IG

Multiplier)

USB

Electronic

Flow

Control

To Controller

Board

Trap

Source

Coupling

Detector

Ion

Amplifier

4000 MS Electronics Block Diagram

Controller

The controller (see block diagram) is the “brains” of the spectrometer, controlling

all operations as well as acquiring all data. The controller executes scan

functions, sets various static voltages and switches components such as valves.

Commands and data are communicated between the controller and the MS

Workstation computer through a universal serial bus (USB) interface.

The processing subsystem of the controller utilizes two TI DSP (Digital Signal

Processing) microchips. The use of two processors allows time critical

operations, handled by the scan processor, to be separated from non-time critical

operations, handled by the communication processor. The processors each have

their own local memory where programs reside and a shared dual processor

memory that is used to hold data and exchange command or status information.

The scan processor handles instrument control, including scan function

execution and data acquisition, in a synchronous manner. Receiving of

commands from the workstation and transmission of accumulated data is

performed asynchronously by the communications processor.

Acquisition method segments are pre-downloaded in their entirety to the

communications processor prior to their execution and stored in shared memory.

The segments are then activated at the appropriate time by the controller.

Multiple method segments can be preloaded. 32 megabytes of dynamic random

access memory (DRAM) is used to store a library of waveforms used for scan

function supplemental waveforms. The combination of preloaded waveform

libraries and preloaded segments eliminates any delays between segments.

22 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...